Ink box for laser printer

A technology of laser printers and printers, applied in optics, electrical recording, instruments, etc., can solve problems such as cumbersome installation process, damage, and complex structure of ink cartridges, and achieve the effect of easy connection and separation, and collision prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

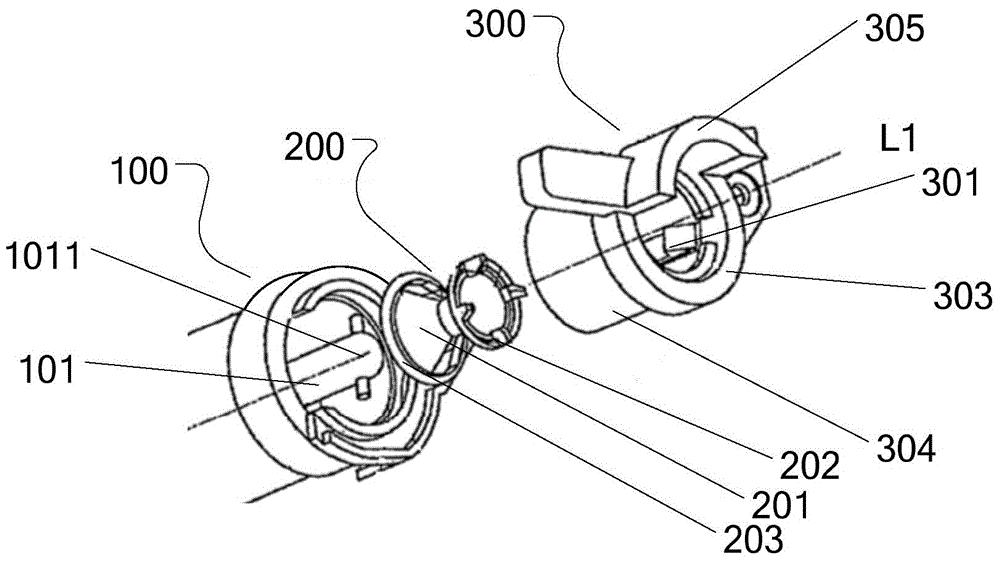

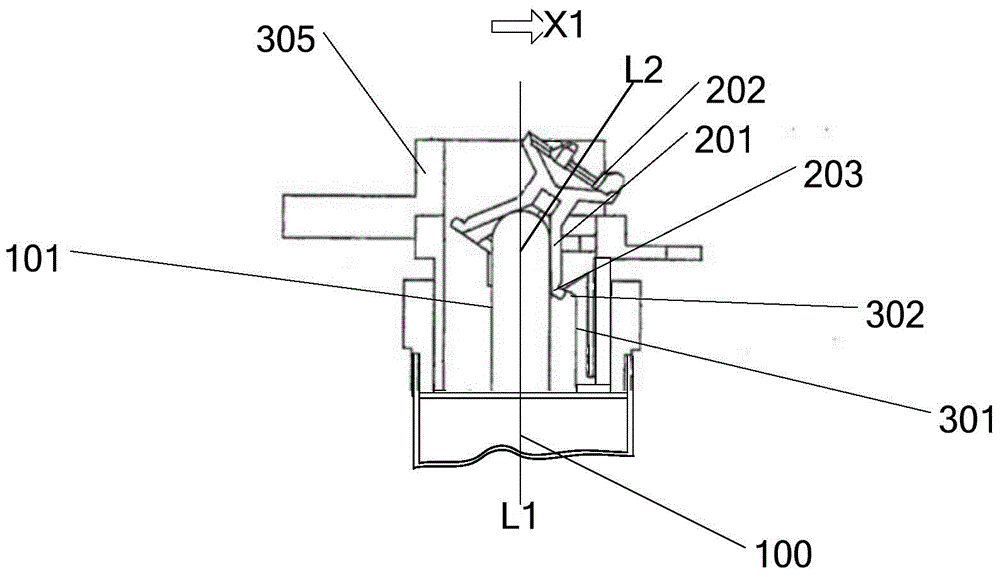

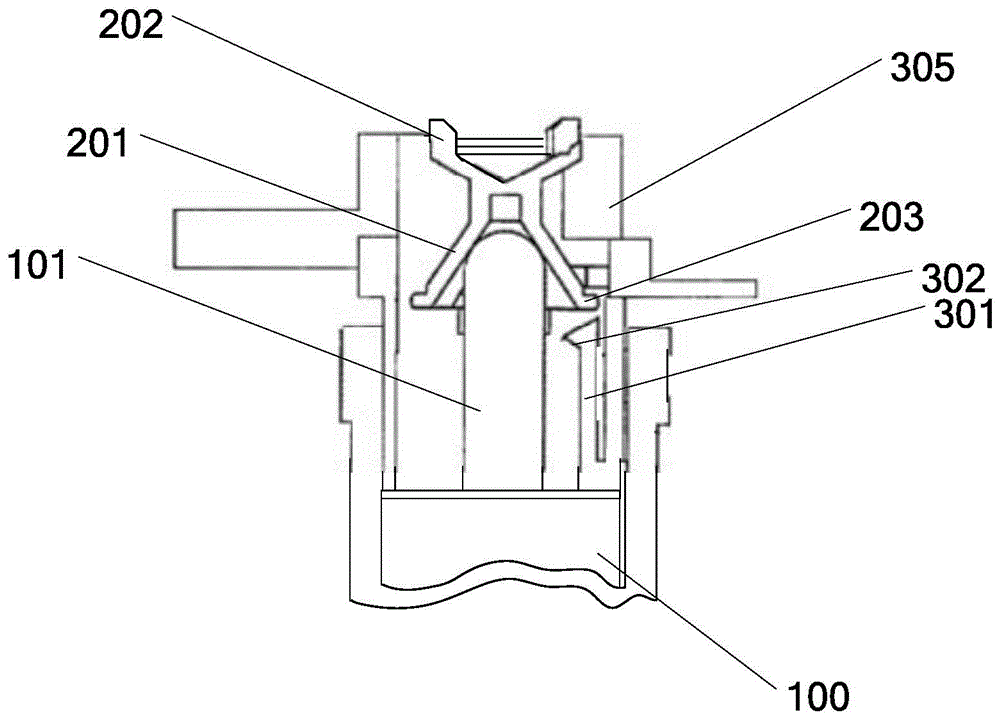

[0020] Such as figure 1 with figure 2 As shown, the laser printer ink cartridge of the present invention includes: a photosensitive drum 100, at least one side of the photosensitive drum 100 is provided with a shaft 101; The free end 202 of the photosensitive drum receives rotational driving force from the printer and rotates; the engaging portion 201 has a flange portion 203 ; the shaft 101 is detachably connected to the printer through the connecting member 200 .

[0021] And the drum receiving part 300, which is ring-shaped and arranged substantially coaxially with the shaft 101, the connecting part 200 is arranged in its inner space, and its inner side wall is provided with a locking part 301, the locking surface 302 of the locking part 301 A part is engaged with the upper surface of the flange portion 201 and at the same time is in contact with the inclined surface of the connector 200 to maintain the inclination angle of the connector 200 . The flange portion 203 is d...

Embodiment 2

[0033]In this embodiment, the locking member 301 is an elastic rib extending perpendicular to the inner surface of the side wall of the drum receiving member 300 . The locking member 301 is provided with an elastic portion. The amount of engagement between the lock piece 301 and the flange portion 203 is reduced. The locking piece 301 is disposed on the most downstream side with respect to the installation direction X1.

[0034] In one of the examples, as Figure 4 As shown, the locking member 301 is arranged upstream relative to the mounting member direction X1. The lock 301 is constituted by a part of the drum support 300 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com