Even-gumming type rubber shoe bottom mold assembly

A sole mold and mold technology, applied in the direction of bonding shoe parts, footwear, shoe-making machinery, etc., can solve the problems of the impact of the firmness of rubber shoes, the lack of technical personnel, and the high production cost, and improve production efficiency and operation convenience. , the operation is convenient and flexible, the structure is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

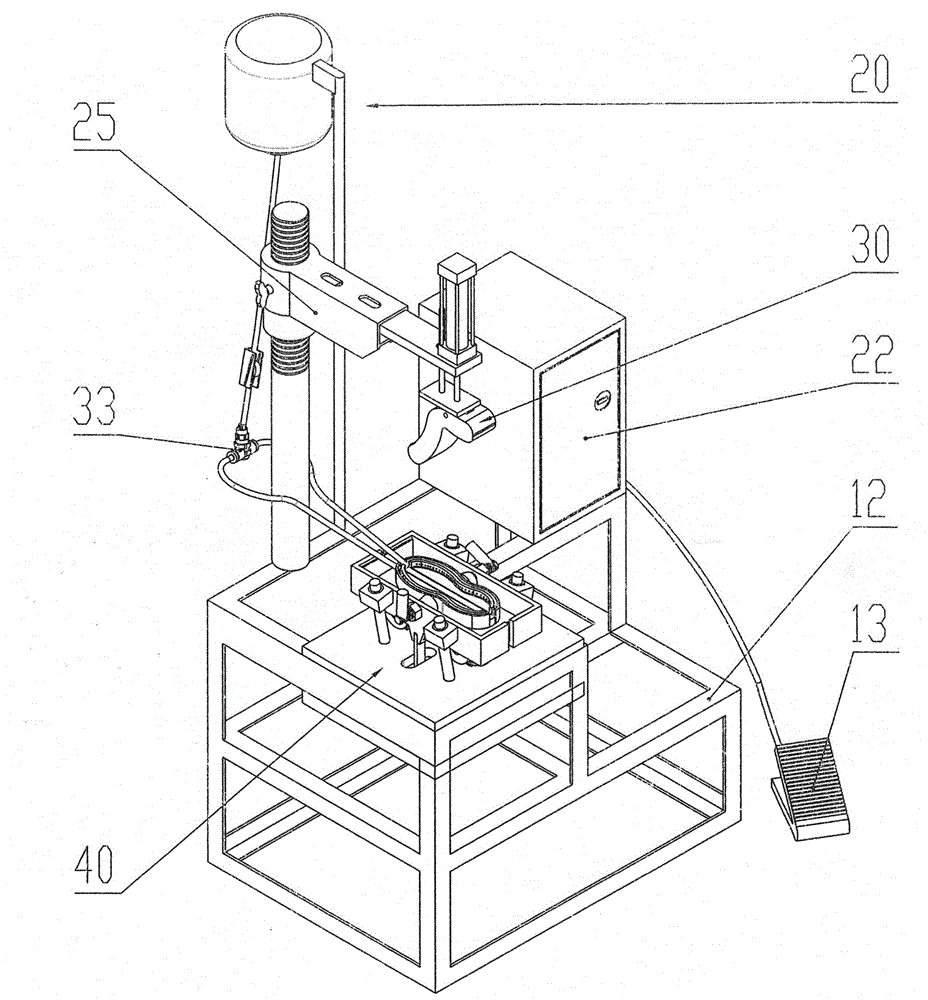

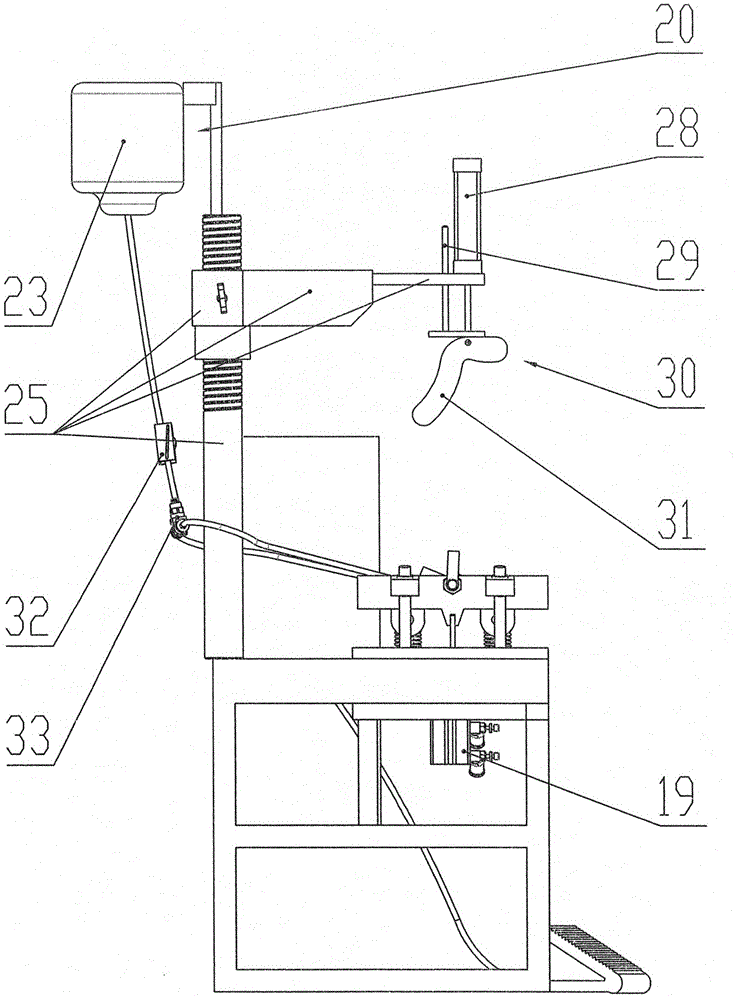

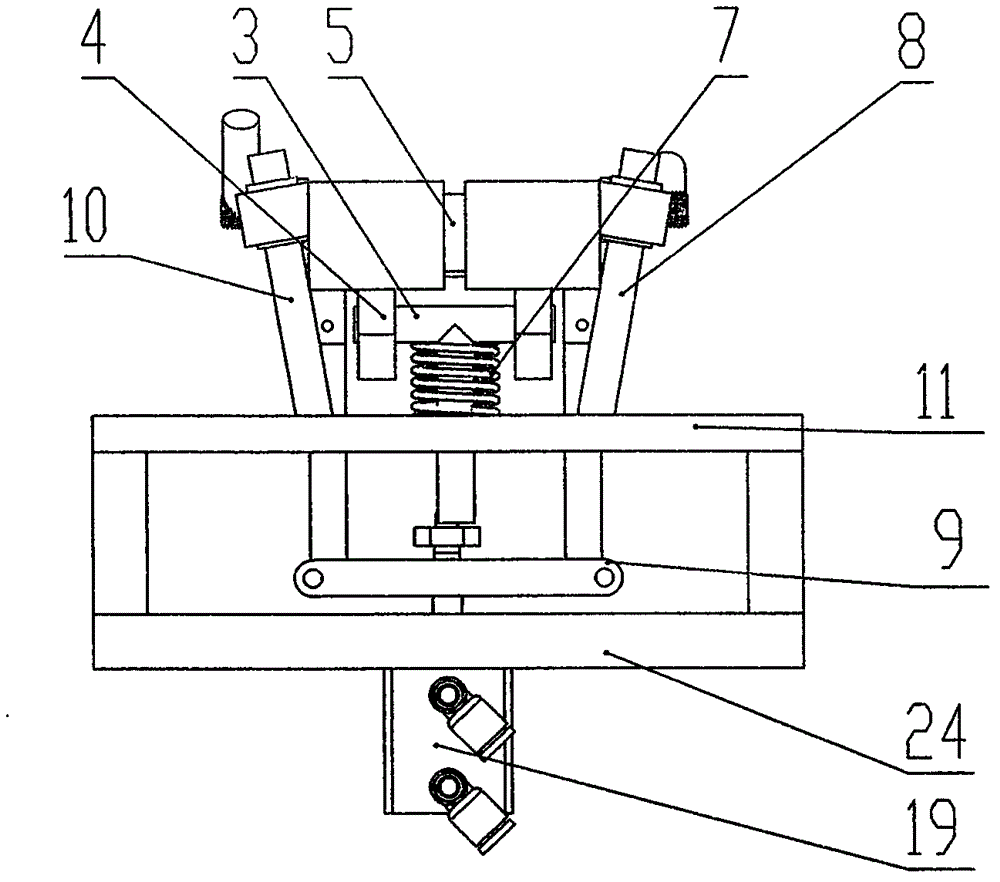

[0015] refer to Figure 3 to Figure 6 It can be seen that the uniform rubber sole mold assembly of the present invention comprises a rubber sole mold (equivalent to the size of the rubber sole), and the rubber sole mold is composed of a left mold 1 and a right mold 6, and the left mold 1 is contained in a left mold box 21, the right mold 6 is installed in the right mold box 26, the inner wall (bottom) of the left mold 1 and the right mold 6 is equipped with a sponge cushion layer 2 (capable of absorbing glue), and in the left The inner walls of the mold 1 and the right mold 6 are all provided with some glue outlet holes 16 (communicated with the glue flow channel 14). The left mold 1 and the right mold 6 are connected by a mold inner tube 5 (preventing glue leakage), and the left mold 1 and the right mold 6 all have glue runners 14, which are all passed through the glue inlet 17. Externally connects into sebific tube 33 (one end). On the inner walls of the left mold 1 and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap