Novel landing-type integral side support of internal mixer

A floor-standing, internal mixer technology, applied in the field of new floor-standing integral side brackets, can solve the problems of micro-movement of the side bracket and the base, uneven locking force, loose bolts, etc., to ensure stability and solve the problem of bolt loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

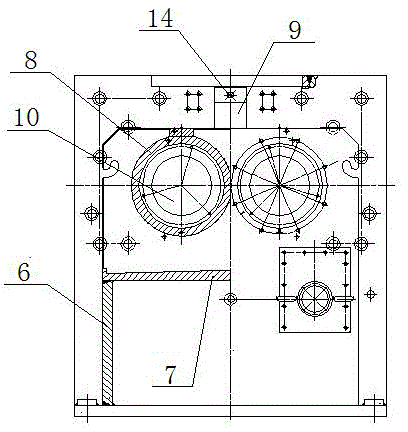

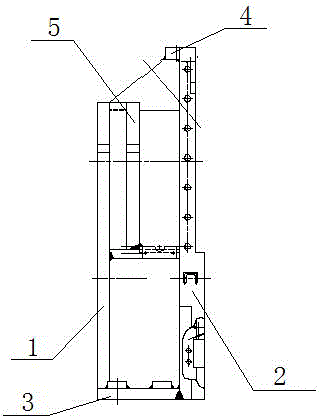

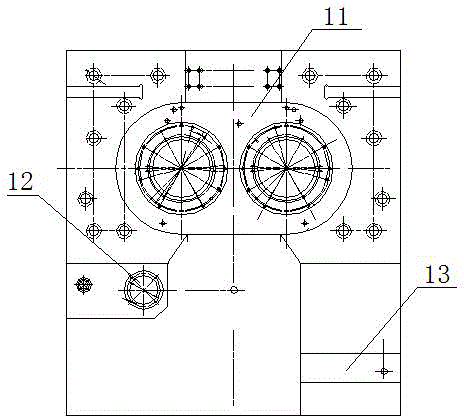

[0015] Such as Figure 1 to Figure 3 As shown, the new floor-standing integral side support of the internal mixer includes outer plate 1, inner plate 2, bottom plate 3, top plate 4, vertical plate 5, side plate 6, partition plate 7 and bearing seat circular plate 8, outer plate 1 , the inner plate 2 and the side plate 6 are respectively fixed on the bottom plate 3, the top plate 4 is installed on the upper end of the inner plate 2, the side plate 6 is arranged between the outer plate 1 and the inner plate 2, the partition plate 7 is installed on the side plate 6, and the vertical plate 5 is installed on the partition 7, the bearing seat circular plate 8 is set on the outer plate 1, the outer plate 1 is provided with bearing holes 10, the outer plate 1, the vertical plate 5 and the inner plate 2 are provided with ribs 9, and the inner plate 2 is provided with a sinking groove 13 for retaining ring installation, the inner plate 2 is provided with a mounting hole 12 for the door ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap