Resin forming device with air-exhaust insert

A technology of resin molding and inserts, applied in the field of resin moldings for lamps and lanterns, can solve the problems of difficult cooling of ventilated metal materials, easy occurrence of shrinkage holes, difficult to repair and blockage, etc., and achieves the effect of easy maintenance and reduction of shrinkage holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the drawings. In the following embodiments, various limitations are made on constituent elements, types, combinations, shapes, relative arrangements, etc., but these are merely examples, and the present invention is not limited thereto.

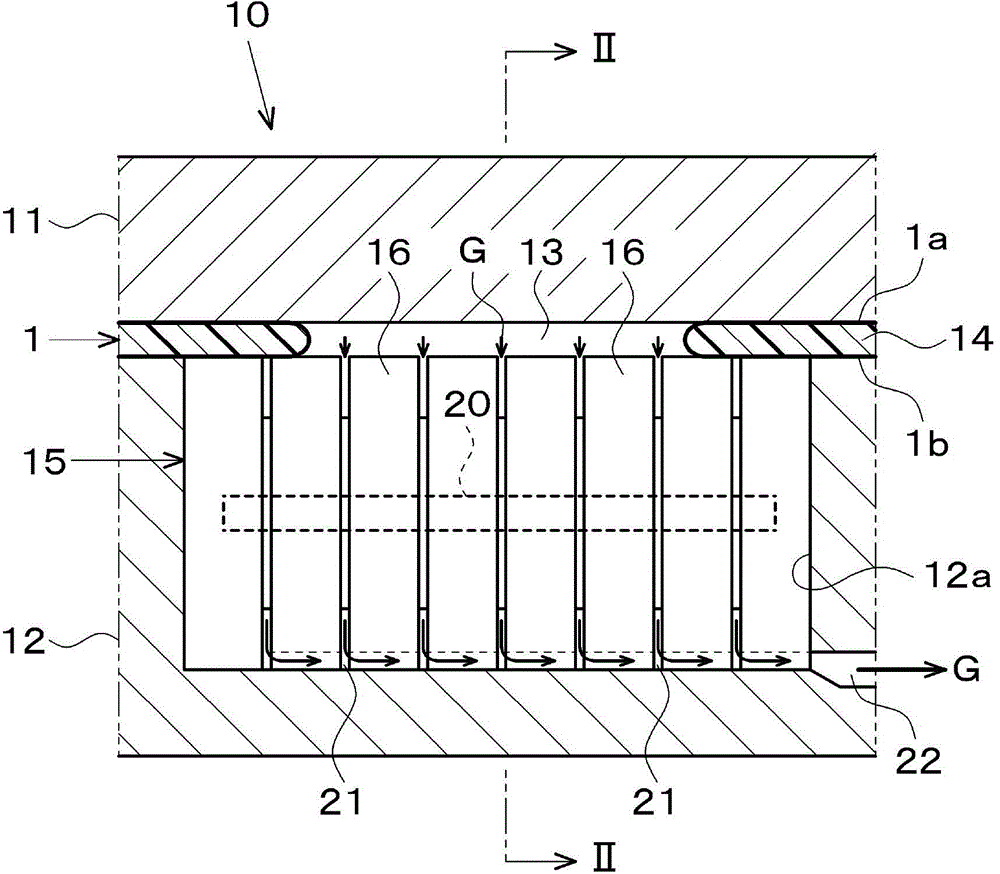

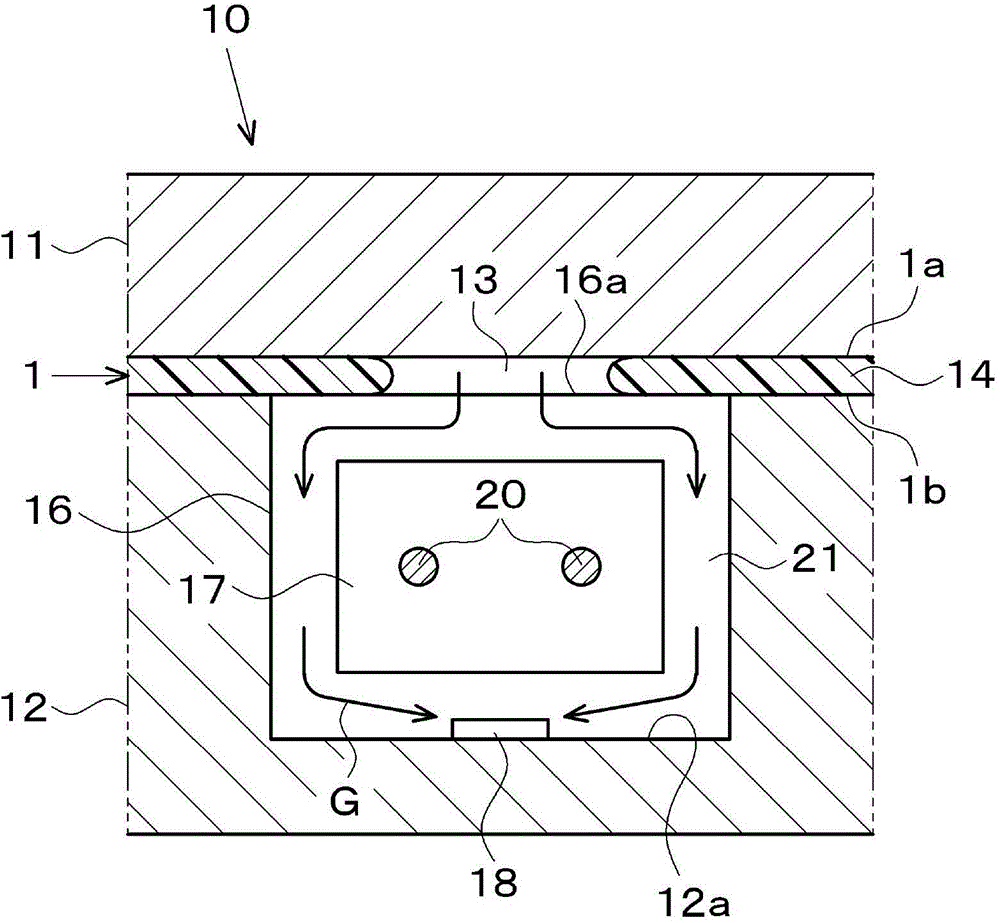

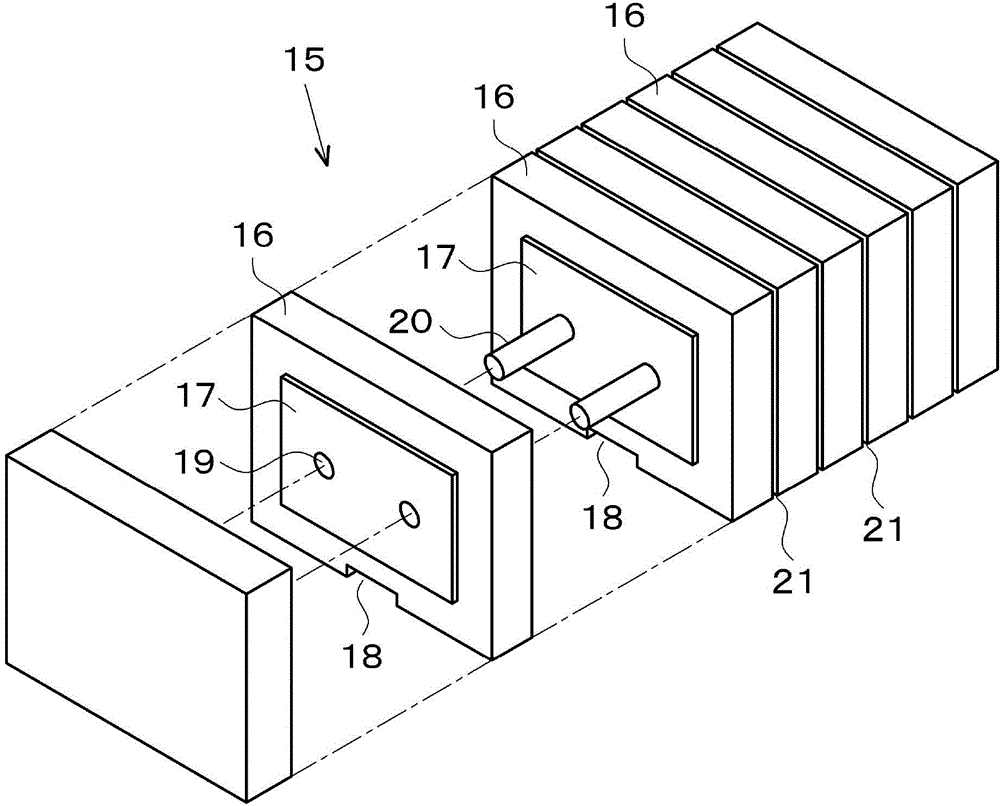

[0048] figure 1 , figure 2 The shown resin molding apparatus 10 includes a steel first mold 11 for molding the front surface 1 a of the resin molded product 1 , and a steel second mold 12 for molding the back surface 1 b of the resin molded product 1 . A cavity 13 is formed between the first mold 11 and the second mold 12 , and a concave portion 12 a is formed in the second mold 12 at a position corresponding to a meeting portion of the molten resin 14 injected into the cavity 13 . Also, an exhaust insert 15 is provided in the concave portion 12a, and the gas G (indicated by an arrow) remaining inside the chamber 13 is exhausted to the outside of the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com