Building material lifting device capable of being locked automatically

A technology of automatic locking and elastic locking device, which is used in elevators, lifts, transportation and packaging in buildings, and can solve the problems of low operation safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

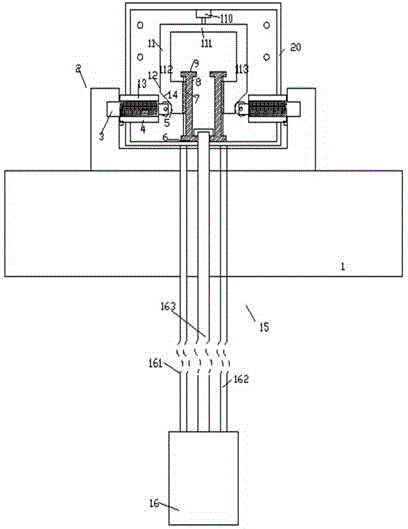

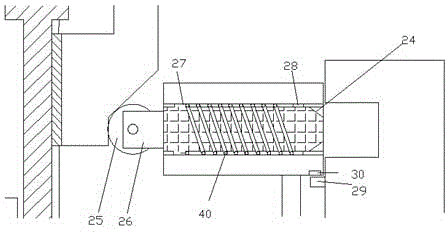

[0015] Combine below Figure 1-2 The present invention will be described in detail.

[0016] The lifting device for building materials that can be automatically locked according to the present invention includes a material basket 1, a locking assembly 20 and a lifting device 15, the material basket 1 is used to hold building materials, and the lifting device 15 is used to lift the material basket For lifting, the locking assembly can be fixed to the building body and can lock the position of the material basket in the raised position;

[0017] The lifting device 15 includes a lifting motor 16, a lifting screw 163 and two guide rods 161, 162, the lower end of the lifting screw 163 is power connected with the lifting motor 16, and the upper end is rotatable with the housing of the locking assembly 20 The lifting screw 163 is threadedly matched with the material basket 1 to lift it, and the two guide rods 161, 162 are fixedly connected to the housing of the locking assembly 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com