Hydraulic lifting platform for built-in lowering operations

A technology of hydraulic lifting platform and working platform, applied in the direction of lifting device, etc., can solve the problems of limited application scope, lifting platform or elevator that cannot maintain and repair the maglev track beam, etc., and achieves the effect of safe and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

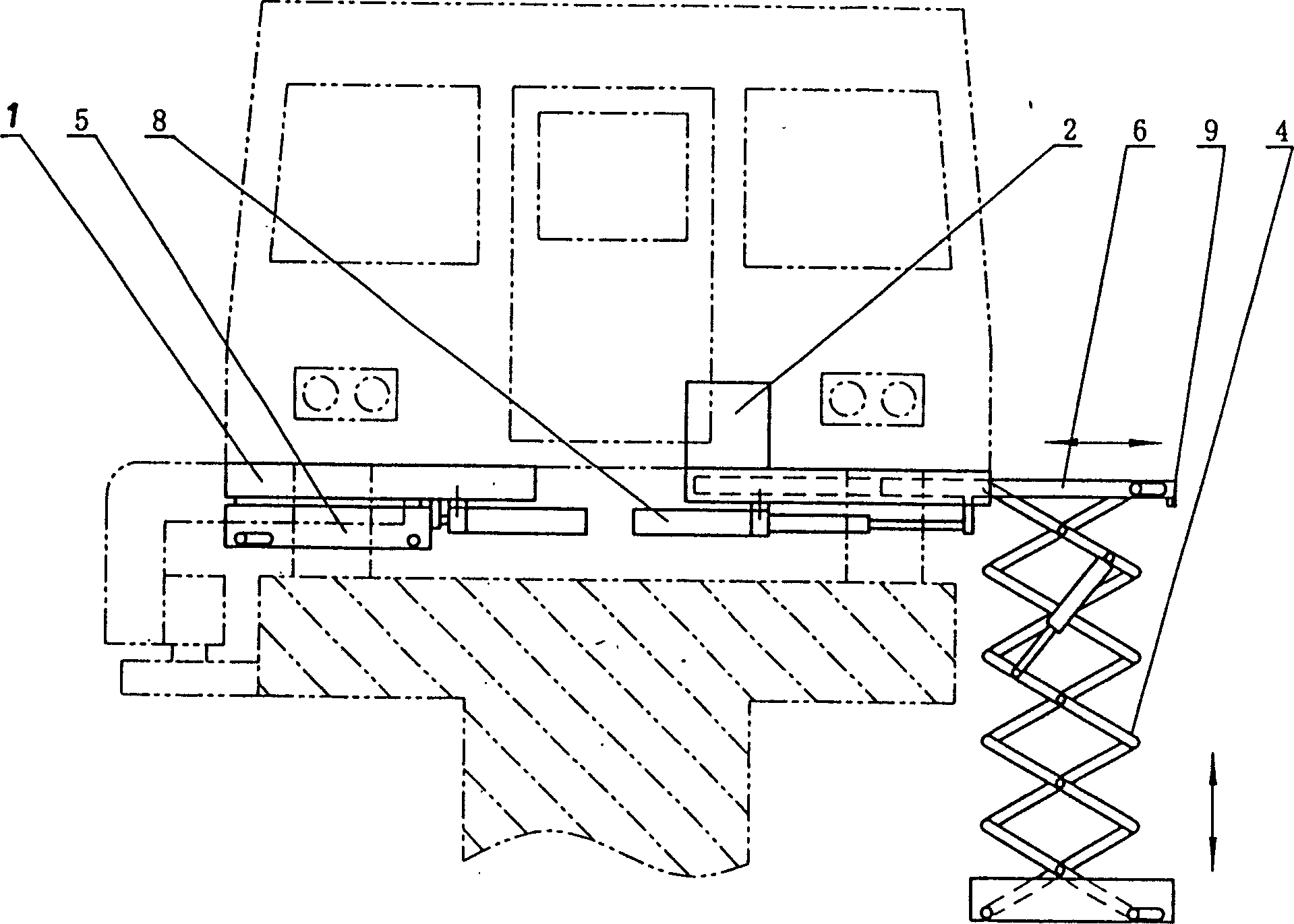

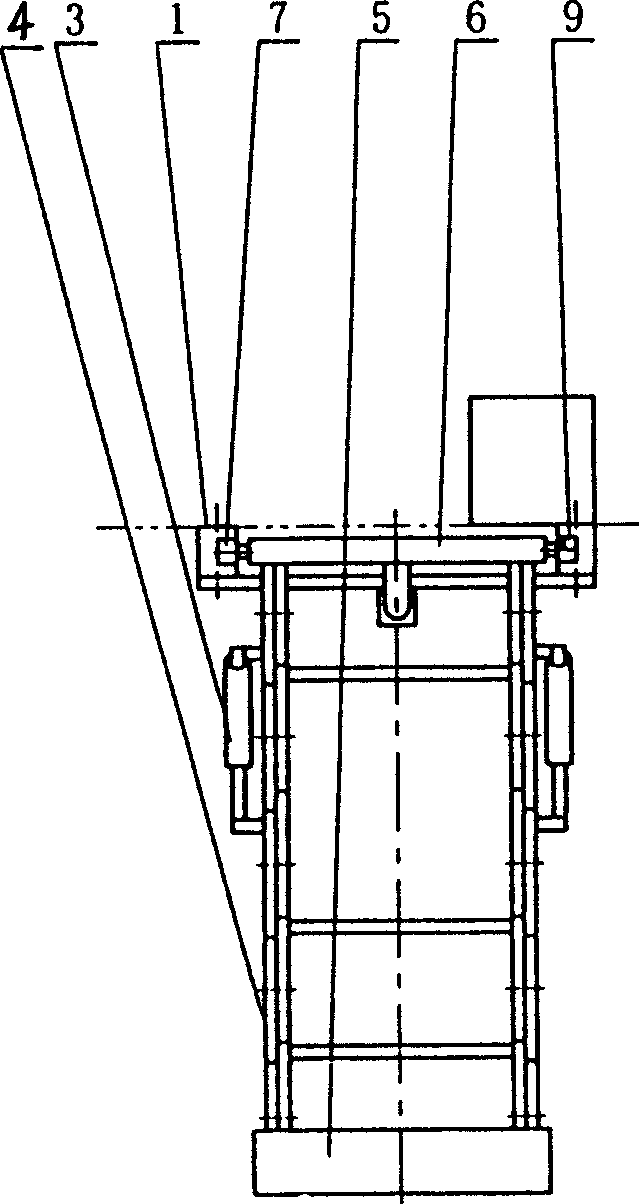

[0010] Such as figure 1 and figure 2 As shown, the present invention includes: a base 1, a hydraulic station 2, a lifting hydraulic cylinder 3, a scissor lifting mechanism 4, a working platform 5, a traversing carriage 6, a roller 7, a traversing hydraulic cylinder 8, and a detection sensor 9. The connection method is as follows: one end of the traversing hydraulic cylinder 8 is hinged on the base 1, and one end of the piston rod is hinged on the traversing carriage 6, and a plurality of rollers 7 are arranged on both sides of the traversing carriage 6. The fork-type lifting mechanism 4 is respectively hinged on the upper and lower ends of the traverse carriage 6 and the work platform 5, the two ends of the lifting hydraulic cylinder 3 are hinged on the scissor-type lifting mechanism 4, and the hydraulic station 2 is fixed on the base 1 or the chassis of the vehicle On the ground or on the floor inside the car body, there are hydraulic oil pumps and oil tanks inside, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com