Method for transporting and mounting hydraulic support in coal mining face

A technology for coal mining face and hydraulic support, which is applied in transportation and packaging, underground transportation, earth-moving drilling, etc., can solve the problems of high energy consumption, difficult maintenance, difficult operation, etc., and achieve safe and reliable lifting and steering, and mechanization. High, high transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

[0025] A method for transporting and installing a hydraulic support in a coal mining face according to the present invention, the method includes the following steps:

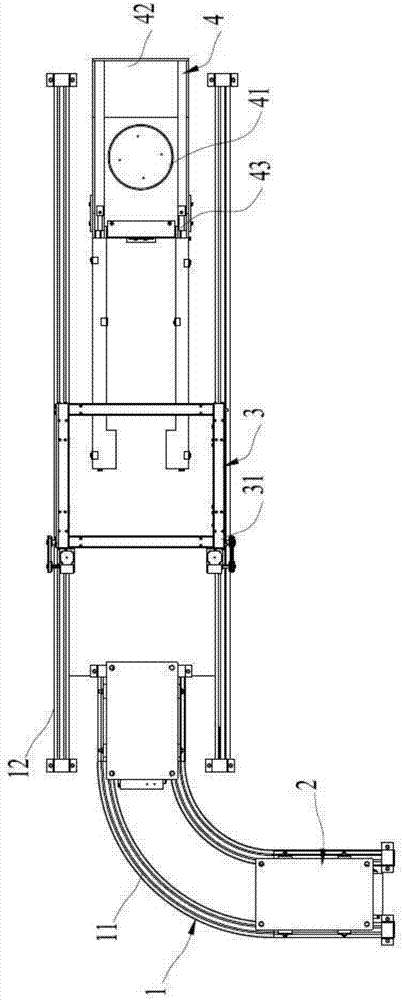

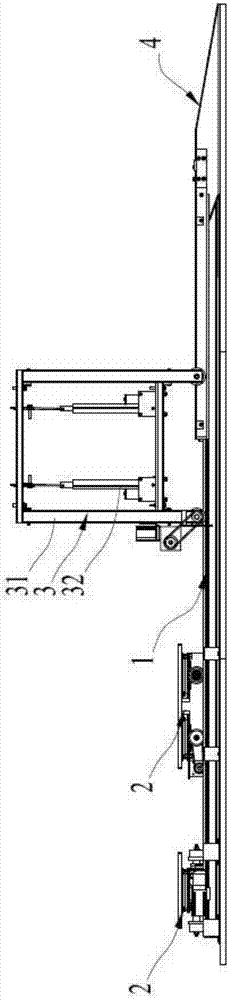

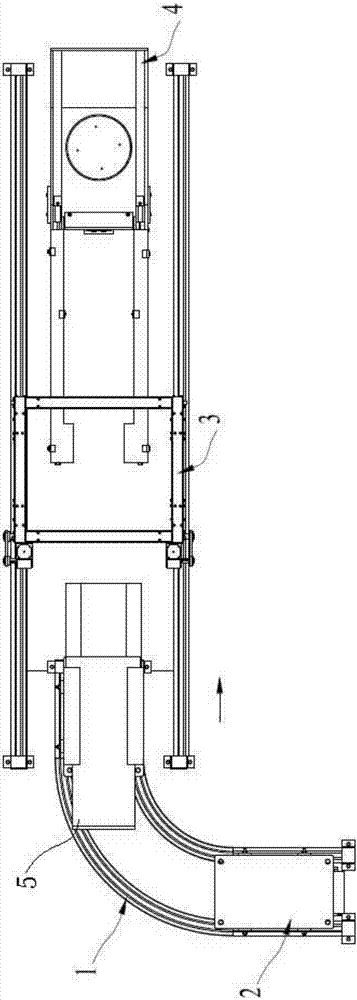

[0026] a) if figure 1 and 2 As shown, the transport track 1 of the hydraulic support 5 is laid, and the transport track is composed of a transport track 11 and a transfer track 12. The transport track 11 is laid in the underground roadway, and the transport track 11 extends to the coal mining face. The support transport vehicle 2 is laid with a transfer track 12 along the coal mining face, a movable support transfer platform 3 is installed on the transfer track 12, and a hoisting device 32 is installed on the support transfer platform 3 through a gantry 31. The designated installation point of the coal working face is provided with an installation machine 4. The installation machine 4 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com