Oxidation-resisting flexible NdFeB pasting magnetic stripe and preparation method thereof

An anti-oxidation and flexible technology, used in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of reduced magnet performance, low bonding strength, easy exposure to air, etc., to improve magnetic performance, strong resistance The effect of oxidative power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

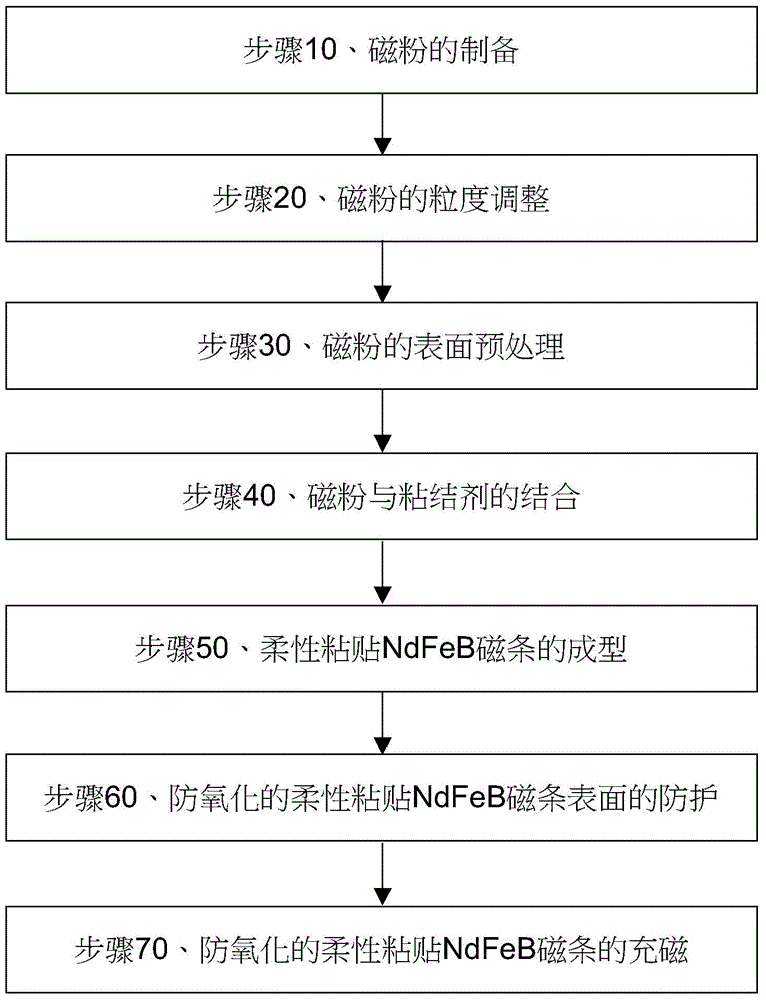

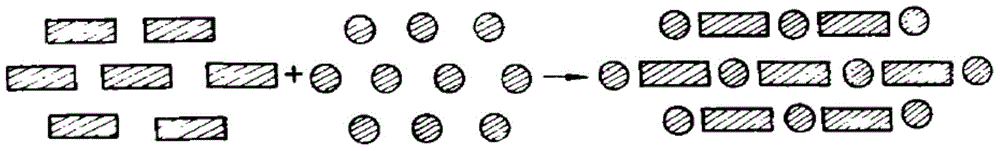

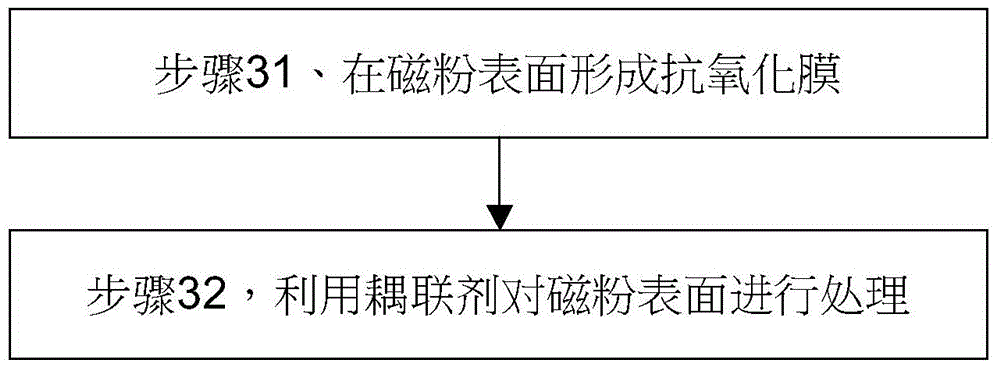

Method used

Image

Examples

Example Embodiment

[0029] Essentially, the flexible bonding NdFeB permanent magnet material is a kind of material with poor corrosion resistance, because neodymium is one of the most chemically active metal elements, and its standard electromotive force E(Nd3+ / / Nd)= -2.431V. In the bonded NdFeB permanent magnet powder, most of the neodymium forms the Nd2Fe14B phase, and there is basically no neodymium-rich phase, and the grain structure is nanostructure, so the corrosion resistance is much better than that of the sintered NdFeB magnet, but it is long-term in the atmospheric environment Exposure will still cause significant oxidation corrosion, which will significantly reduce the magnetic properties. There are two factors that cause the decrease of magnetic performance: one is that the neodymium element generates oxides after oxidation, the excess iron is precipitated, and the soft magnetic phase is formed, resulting in the reduction of the permanent magnetic phase; the second is that the soft mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com