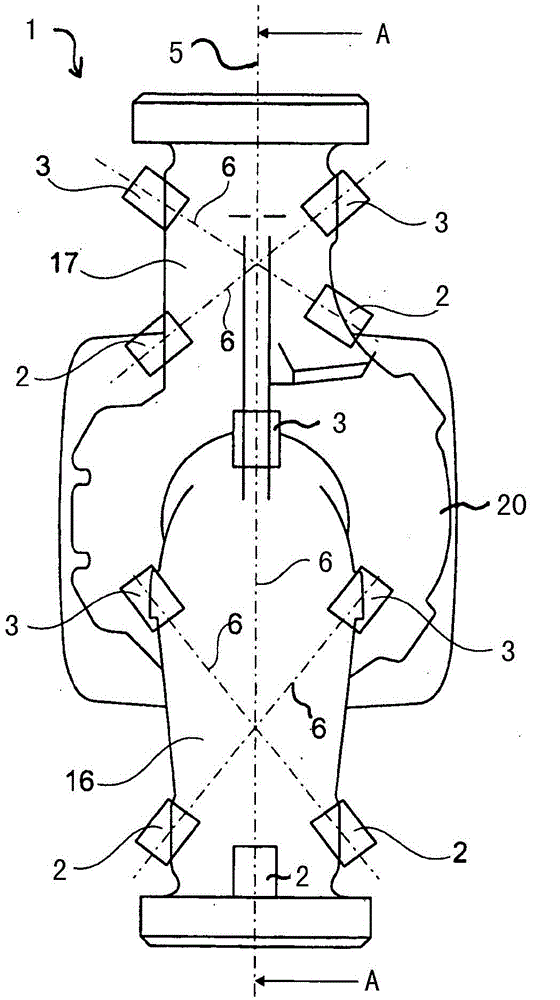

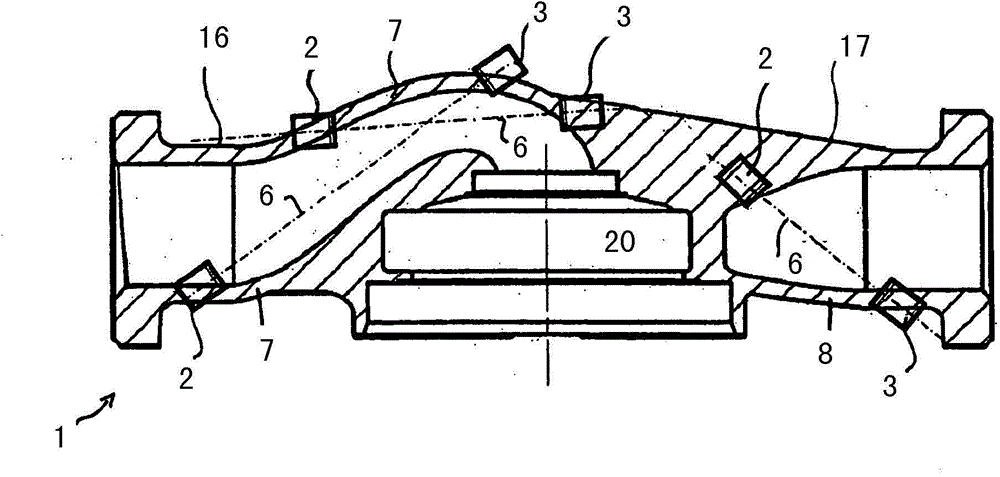

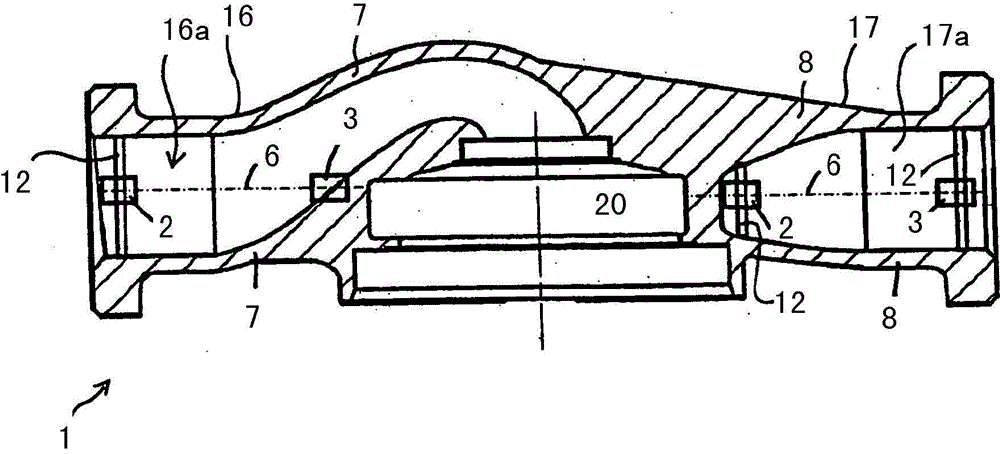

Centrifugal pump with ultrasound flow-through measurement device

A technology of rotary pump and flow measurement device, applied in liquid/fluid solid measurement, measurement flow/mass flow, pump control, etc., which can solve the problems of reducing the volume flow range and deteriorating measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] The pump according to the invention can be a solar pump in which, for example, a flow measuring device for heat detection (revenue detection) is integrated. In general, the pump according to the invention can be integrated in a solar system for function control. Alternatively, the pump may be a fresh water station pump, a heat pump or a metering pump. As a heat pump, the flow measuring device can also be used for heat metering. Finally, the flow measuring unit can also be used for power measurement or power regulation of pumps or pump systems. The pump 1 can be a wet rotor or a dry rotor.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap