Double-row-seeding seed-metering device of alfalfa

A technology of alfalfa and seed metering device, which is applied in sowing, seeder parts, applications, etc., can solve the problems of low seeding efficiency, difficult control of seeding rate, and poor seeding uniformity, so as to improve seeding efficiency and prevent arbitrary sprinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

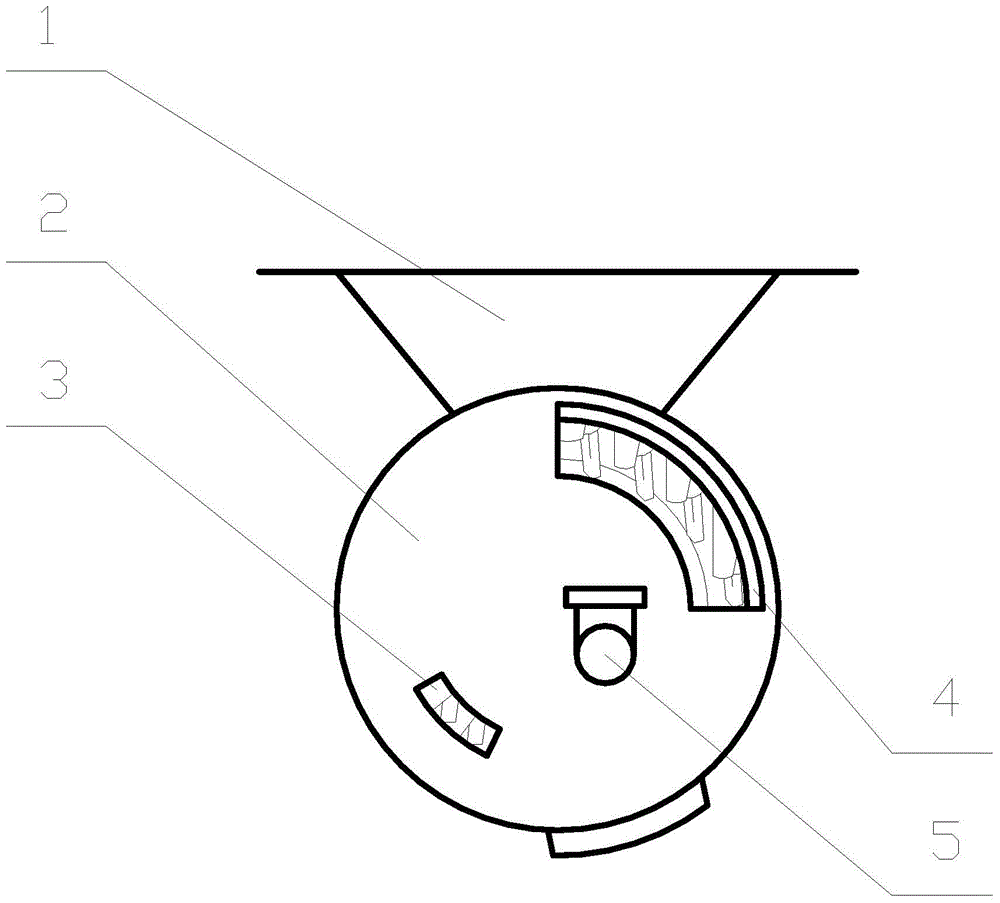

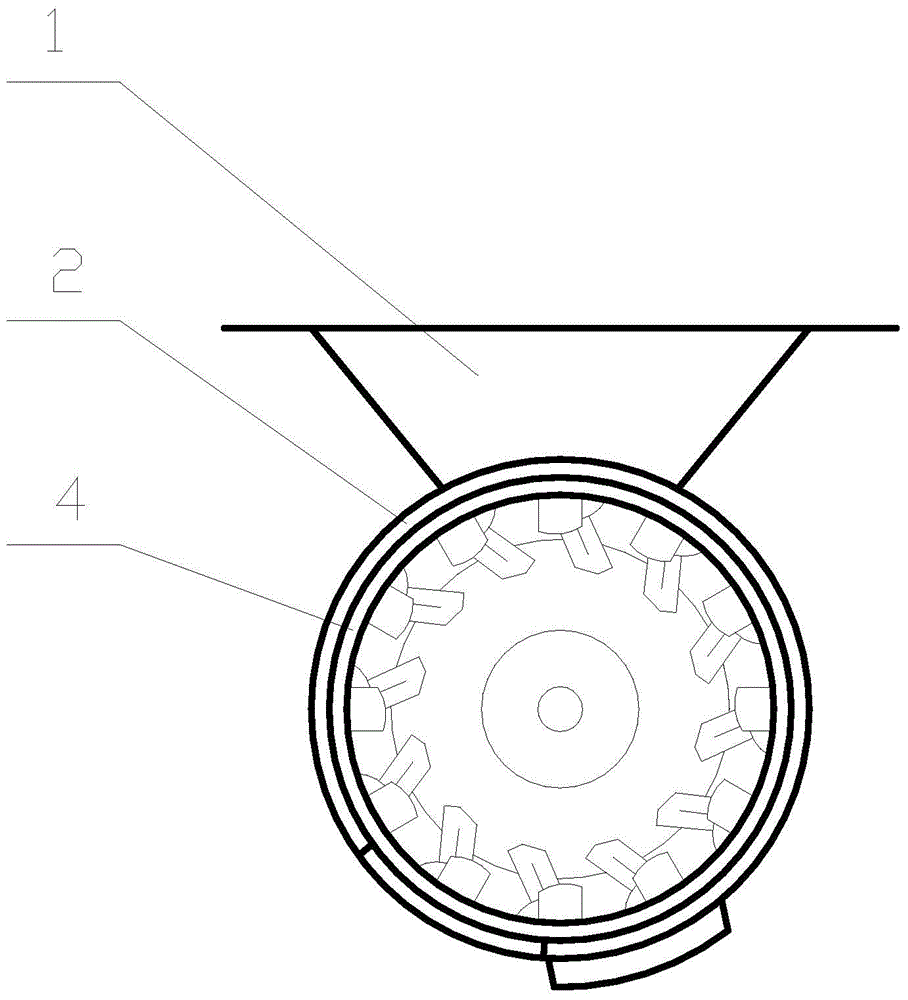

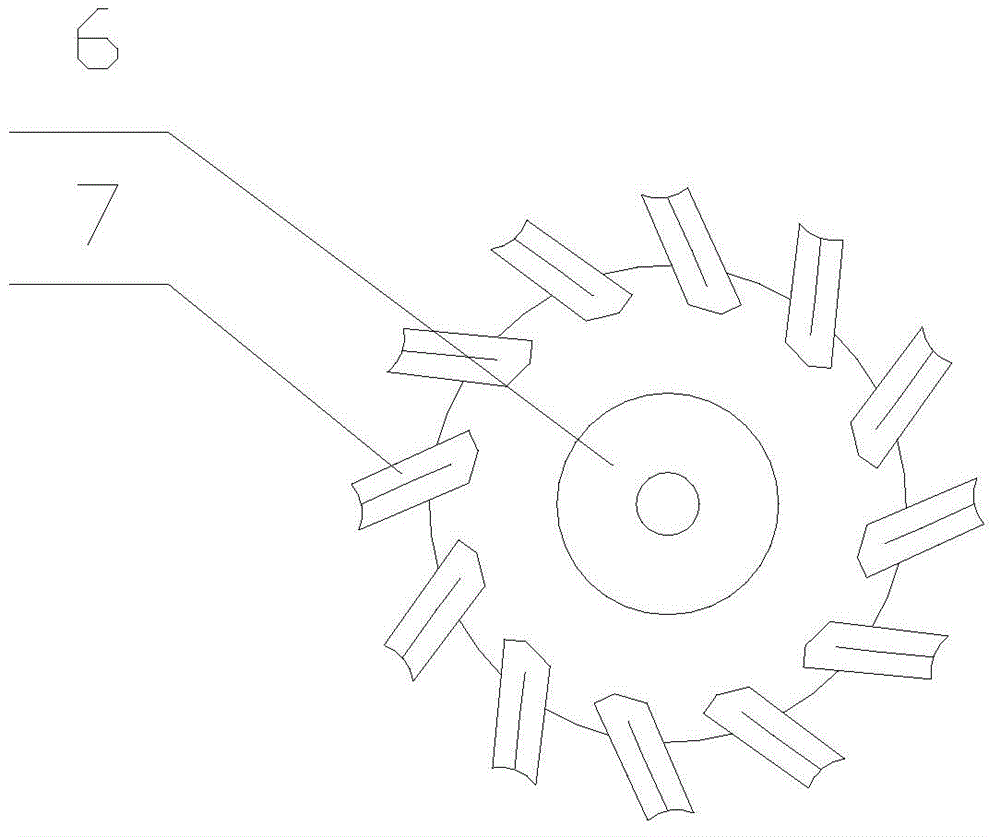

[0025] The following will be combined with figure 1 , 2 , 3, 4, 5 further illustrate the present invention.

[0026] The present invention is composed of a seed hopper 1, a casing 2, a seed discharge port 3, an elastic material 4, a spoon wheel 6, a helical tooth 7, a seed guide wheel 8, a seed guide tooth 9, a seed guide groove 10, and a neutral gear 11, specifically : the inner ring of the shell 2 is provided with an elastic material 4, and a seed guide wheel 8 and a scoop wheel 6 are coaxially installed side by side at the same time, the top of the shell 2 is provided with a seed hopper 1, and the bottom of the shell 2 is provided with a seed discharge port 3, said The seed guide wheel 8 circumference is evenly provided with guide seed teeth 9, and the circumference of the spoon wheel 6 is evenly provided with helical teeth 7, and the described seed guide teeth 9 are provided with a seed guide groove 10, and the seed guide groove 10 edge There is neutral gear 11 at the pl...

example 2

[0029] The following will be combined with figure 1 , 2 , 3, 4, 5 further illustrate the present invention.

[0030] The present invention consists of a seed hopper 1, a casing 2, a seed discharge port 3, an inspection hole 5, a spoon wheel 6, a helical tooth 7, a seed guide wheel 8, a seed guide tooth 9, a seed guide groove 10, a neutral gear 11, and a baffle plate 12. The composition is specifically as follows: inside the casing 2, a seed guide wheel 8, a baffle plate 12, and a spoon wheel 6 are installed side by side and coaxially, the top of the casing 2 is provided with a seed hopper 1, and the bottom of the casing 2 is provided with a seed discharge port 3 , There is an inspection hole 5 on one side of the shell 2. The circumference of the described seed guide wheel 8 is uniformly provided with seed guide teeth 9, and the circumference of the spoon wheel 6 is uniformly provided with helical teeth 7, and the described seed guide teeth 9 are provided with a seed guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com