Pat-type oilseed rape threshing machine

A technology for thresher and rapeseed, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of slow detachment, low work efficiency, waste, etc., and achieve the effect of good threshing effect, high work efficiency, and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

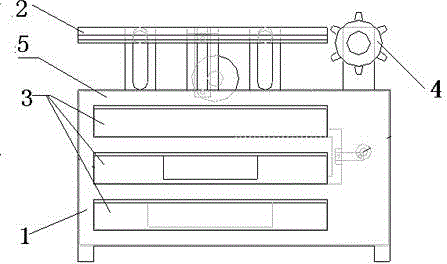

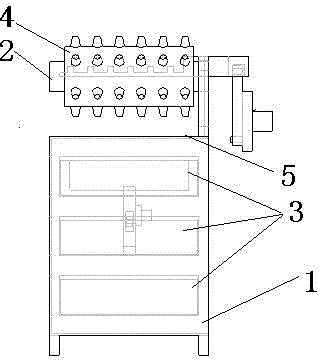

[0011] Such as Figure 1-Figure 2 Shown, the present invention comprises frame 1, and the top of frame is provided with platform 5, and the top of platform is provided with beating board 2, and the bottom of platform is provided with 3 mesh screens successively from top to bottom, and the hole of mesh screen is arranged from top to bottom. It gradually becomes smaller from the bottom, and one end of the platform is provided with a roller 4 for compacting the feed material. In the machine, the beating plate 2, the mesh screen 3 and the rollers 4 are respectively connected to the driving device, and the beating plate is driven to swing up and down, the mesh screen horizontally swings and the rollers are rotated.

[0012] When in use, hold the root of the rape plant so that the rape stalk at the top enters the gap between the roller and the platform, the rape stalk squeezed by the roller is no longer loose, and many rape siliques have been broken, and then enter the platform, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com