whiteboard eraser automatic washing machine

A washing machine and automatic technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as waste, manpower and material resources, and inability to wring out, so as to reduce production costs and clean The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings.

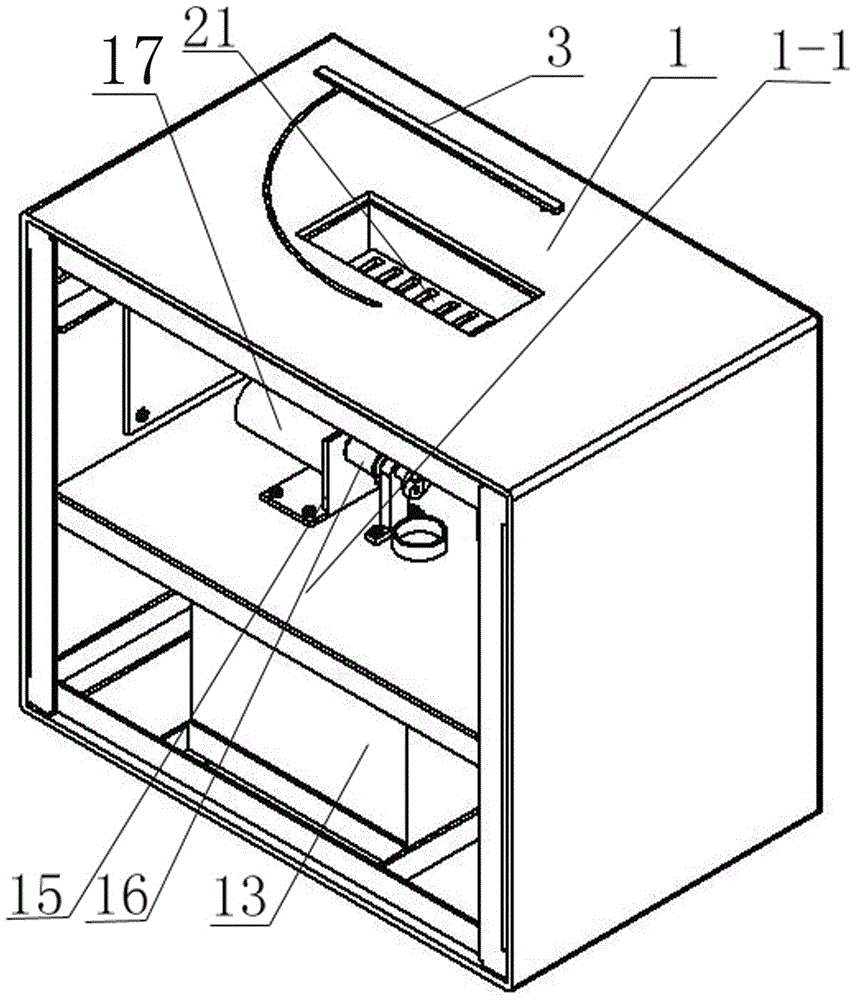

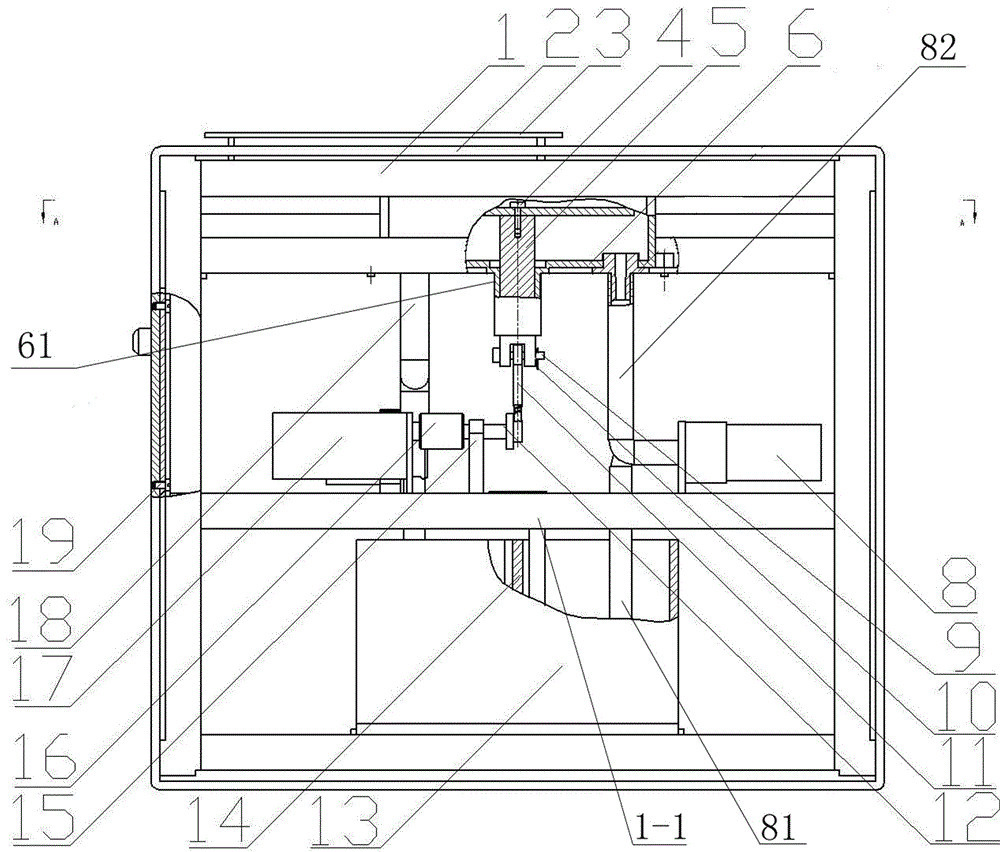

[0020] Such as Figure 1-5 As shown, the present invention includes a frame 1, a washing box 6, a motor 17, a slider shaft 5, a crank 11, a liquid storage tank 13, a water pump 8, a washing plate 21, a steering gear 23, a clamping rod 3 and a control circuit board 25 The frame 1 is made of aluminum profile, the outer side of the frame 1 is installed with a shell 2, and the middle of the frame 1 is provided with a partition 1-1. The washing box 6, the motor 17, the water pump 8, the liquid storage tank 13, and the steering gear 23 are installed on the frame 1. The motor 17 and the water pump 8 are respectively installed on the partition 1-1 by four screws I 19, so The liquid storage tank 13 is located below the partition 1-1, and the washing box 6 is located above the partition 1-1.

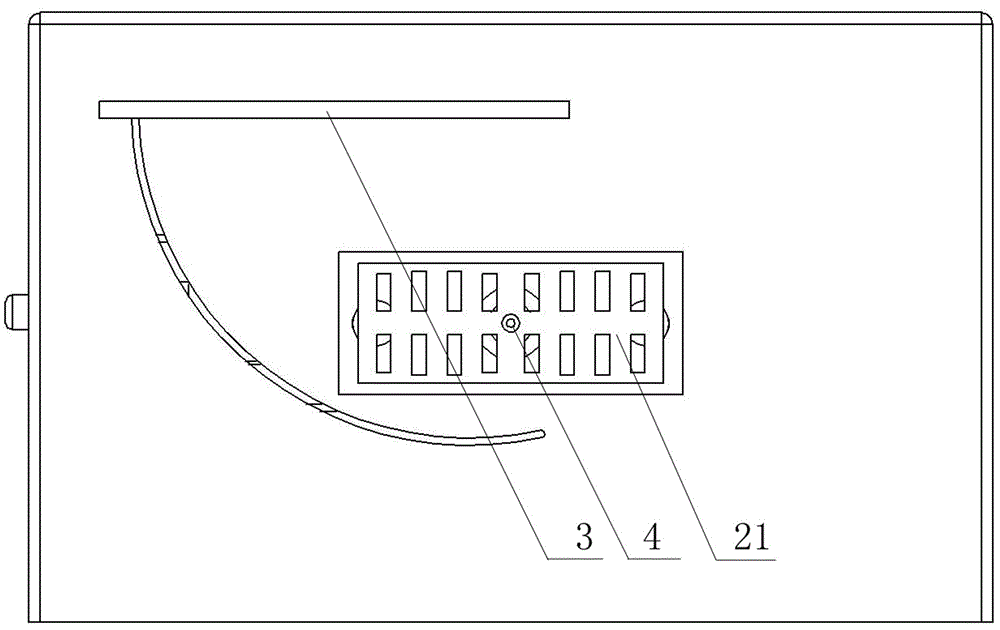

[0021] The washing board 21 is provided with 16 rectangular frames, which increases the pressing press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com