In-place measurement method for thickness of large-sized wall plate

A large-scale panel and measurement method technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing, etc., can solve the problems of low measurement efficiency and inability to obtain comprehensive data of the panel, so as to improve work efficiency and test The effect of improving efficiency and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

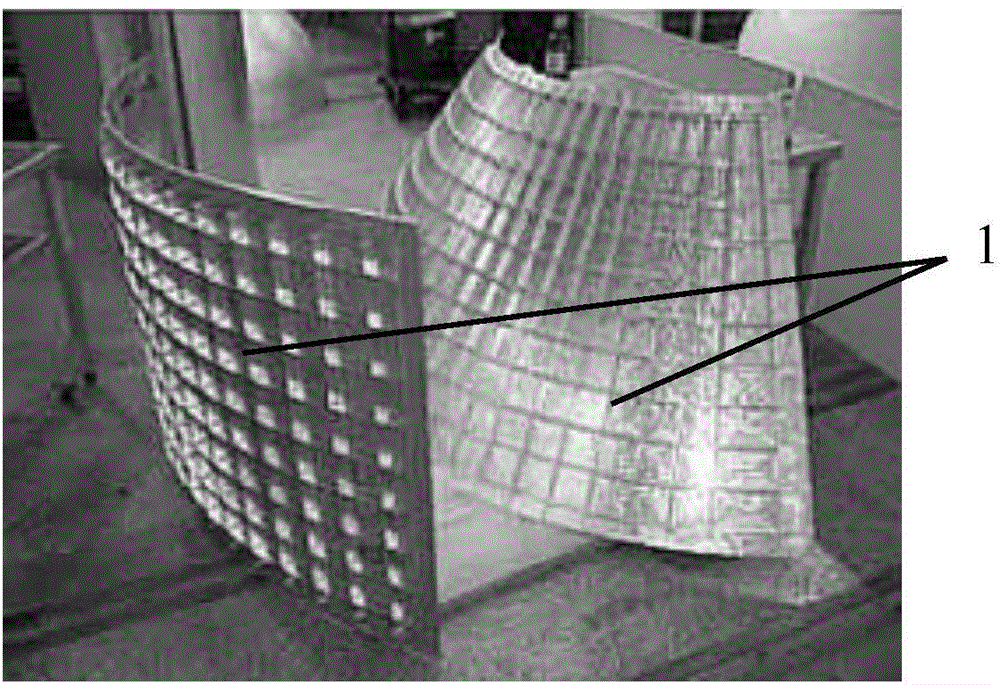

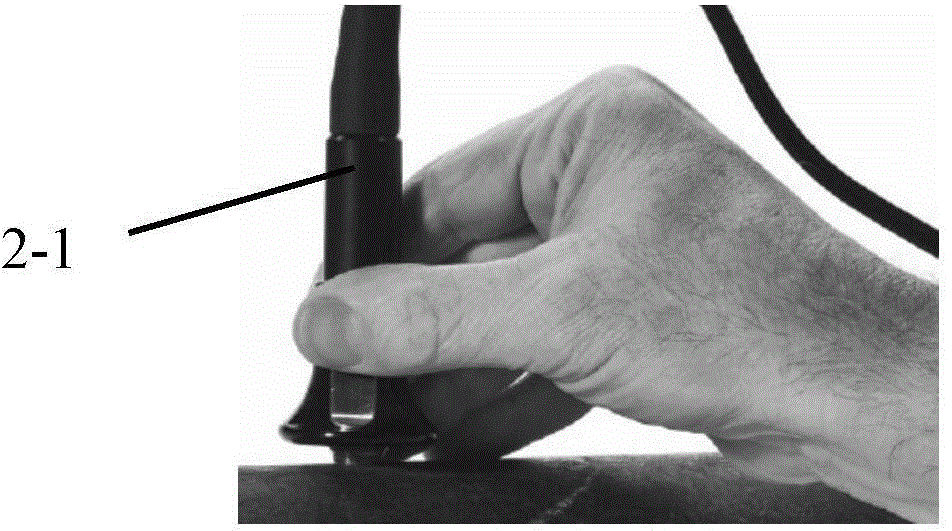

[0024] Specific implementation mode one: as Figure 1~5 As shown, the method described in this embodiment is implemented based on the measurement system, and the measurement system mainly includes ultrasonic thickness gauges, precision tooling, data transmission processing modules, special software, and terminal processing equipment.

[0025] An on-site measurement method for the thickness of a large wall plate, the measurement method is realized based on a measurement system including an ultrasonic thickness gauge, a data transmission processing module, a card loading mechanism and a terminal processing device, and the ultrasonic thickness gauge and data transmission The processing module is installed on the CNC milling machine used to process large wall panels with precision tooling;

[0026] The realization process of described method is:

[0027] Step 1. After the CNC milling machine has processed the grid-shaped reinforced wallboard, remove the milling cutter on the CNC ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap