Non-setting adhesive mold and method for fabricating facing bricks on site using mold

A decorative brick and self-adhesive technology, which is applied in the field of building materials construction, can solve the problems of reduced weight of the overall decorative layer, roughening of the molding surface, and water seepage of the decorative layer, so as to achieve no flash, regular molding surface, and color blocks of the facing brick uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

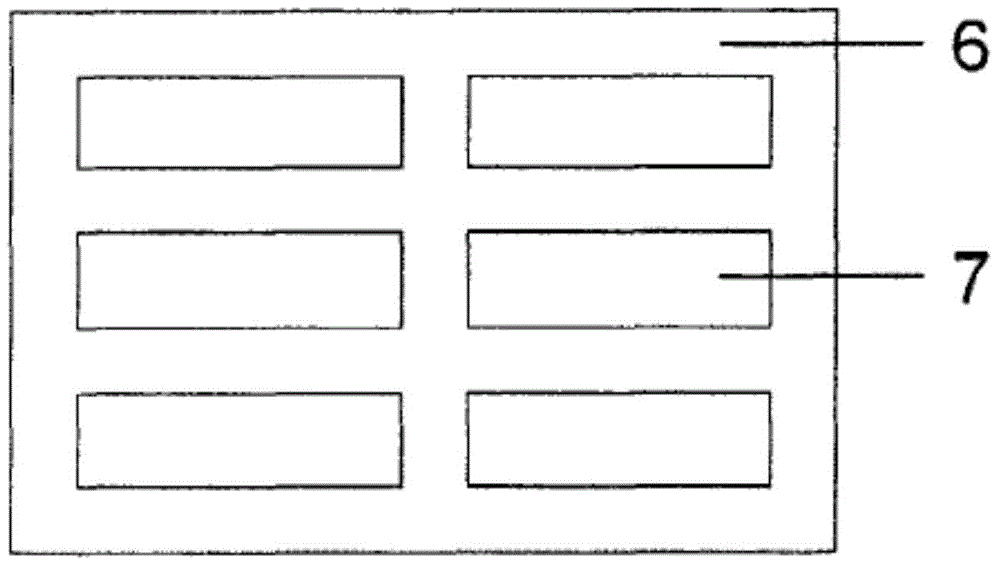

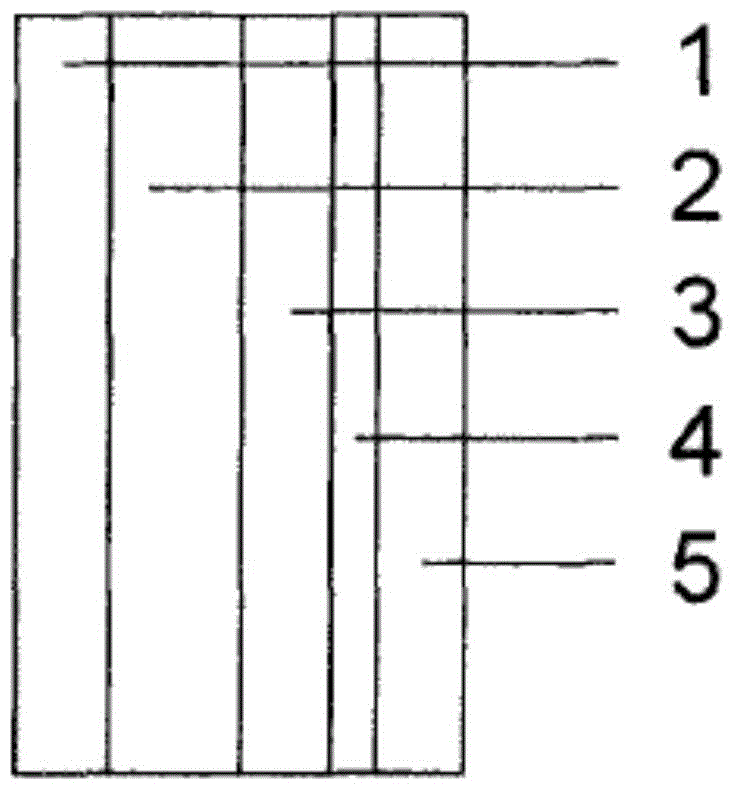

[0063] figure 1 It is a schematic diagram of the front side of the wall facing brick mold that can be demoulded at one time. figure 2 It is a schematic side view of a wall facing brick mold that can be demoulded at one time.

[0064] Such as figure 1 As shown, a wall facing brick mold for making facing bricks on the surface of a building has a sheet-shaped hollow structure, and the mold body 6 has hollow brick-shaped holes 7 . The total thickness of the sheet hollow mold is figure 2 The total thickness of each layer is about 0.6mm.

[0065] Such as figure 2 As shown, wherein, the mold includes a release layer 1, a self-adhesive adhesive layer 2, a bottom layer of coated paper 3, a paper body 4, and a surface layer of coated paper 5 from the inside to the outside. The thickness of the bottom layer coated paper 3 is about 0.05mm. Outer layer surface layer coated paper 5 is positive colored coated film, to distinguish the front or the back side of mold conveniently, its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com