Screw mechanism with adjustable pre-tightening force

A set screw and screw technology, which is applied in the connection of screws, nuts, rods, etc., can solve the problems of spherical locking screws, such as easy damage, short service life, and insufficient stability of the mechanism, and achieve stable and reliable locking and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited accordingly.

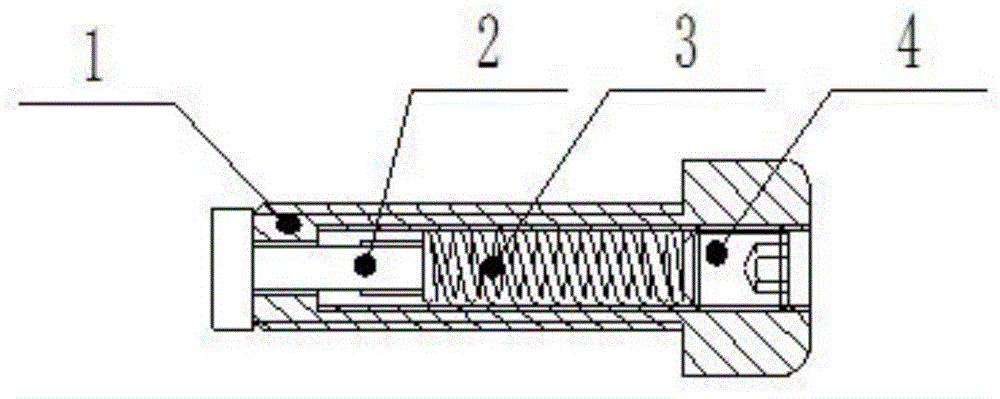

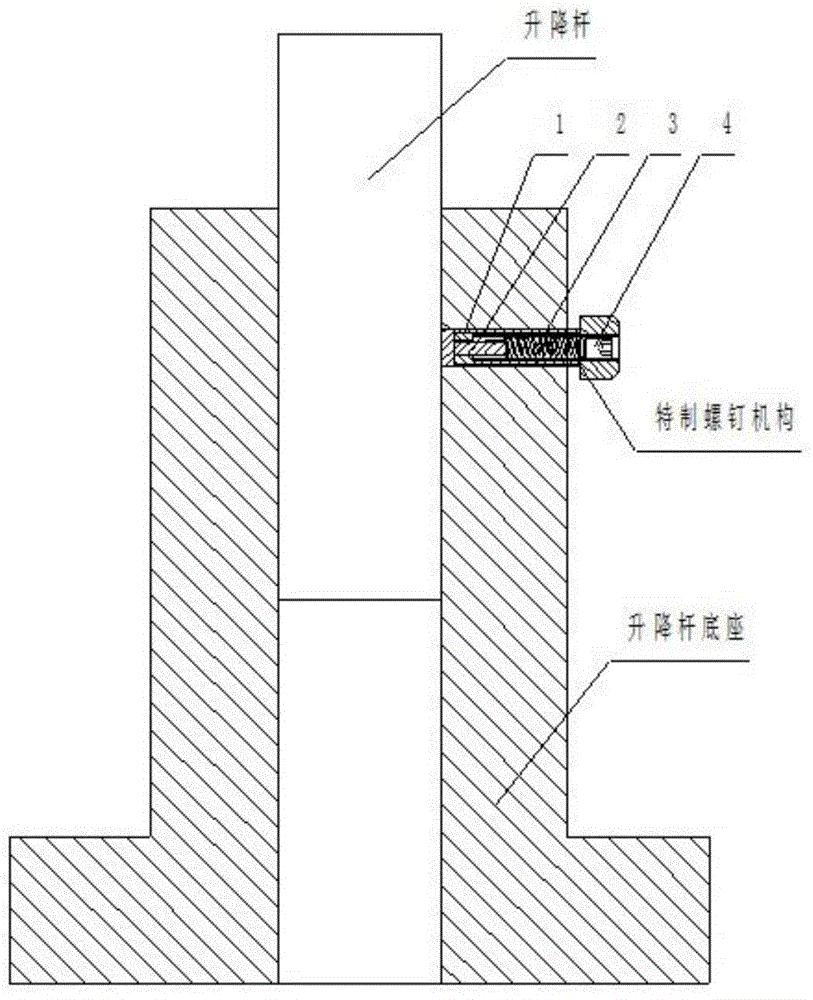

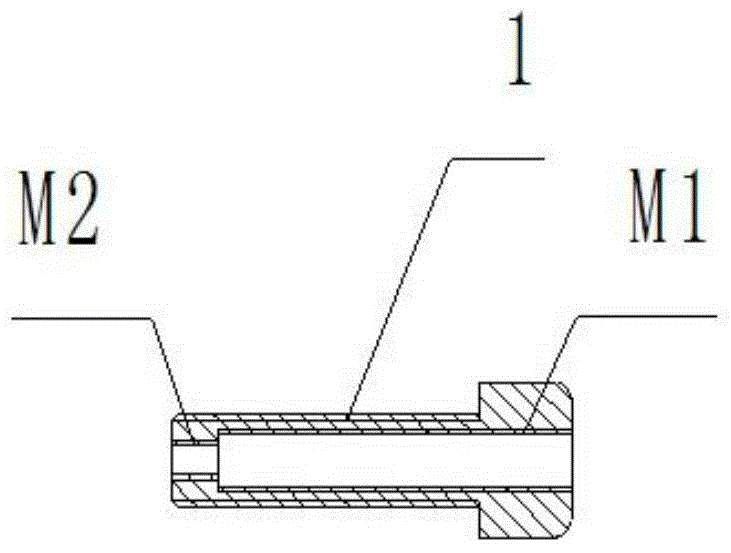

[0015] see figure 1 , figure 2 , figure 1 It is a cross-sectional view of the screw mechanism with adjustable preload of the present invention. It can be seen from the figure that the screw mechanism with adjustable preload of the present invention consists of a screw 1 with an internal stepped threaded hole, a stepped cylindrical boss 2, and a compression spring. 3. Set screw 4, the internal stepped threaded hole screw 1 has external thread and internal stepped threaded hole, and the internal stepped threaded hole is divided into two sections along the axial direction: the long internal threaded hole is a fine-pitched internal screw hole M1, the short-section internal threaded hole is an ordinary internal screw hole M2, the tail of the smaller outer cylinder of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com