Two-stage variable displacement oil pump

A displacement machine and variable technology, which is applied to lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of high cost of solenoid valve oil pumps and restrictions on the layout of oil pumps, and achieve low cost, flexible layout, and stable oil output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

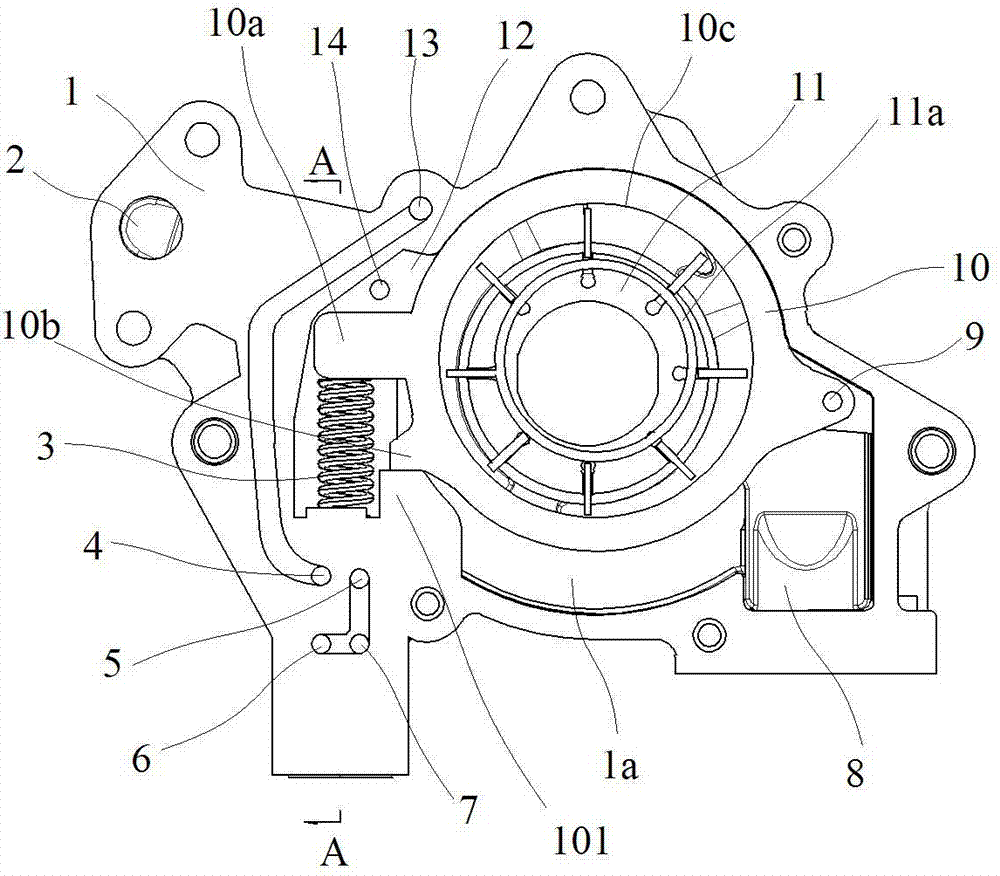

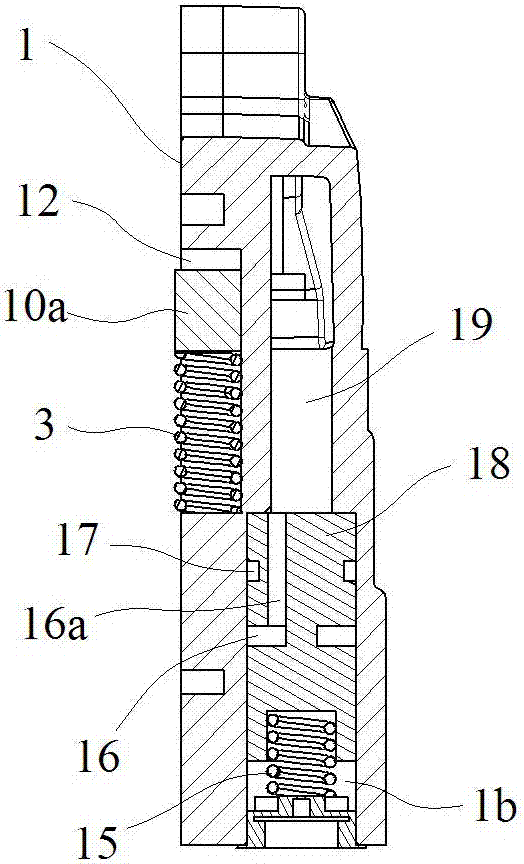

[0019] like figure 1 In the illustrated embodiment, a two-stage variable displacement oil pump includes a pump body 1 , a rotor 11 , an adjusting ring 10 and a mechanical valve. Wherein, the pump body 1 is provided with an oil inlet 8, an oil outlet 2, and an inner cavity 1a, and both the adjusting ring 10 and the rotor 11 are located in the inner cavity 1a, the adjusting ring 10 is provided with a circular inner hole 10c, and the rotor 11 is located in the inner cavity 1a. The rotor 11 is provided with a vane 11a that can move radially along the rotor 11 as the rotor 11 rotates in the inner hole 10c and is arranged eccentrically relative to the inner hole 10c. The adjustment ring 10 is provided with a rotating positioning end on the side close to the oil inlet 8, and the rotating positioning end is rotationally connected with the pump body 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap