An antique wood floor processing machine

A technology for processing machines and wood floors, applied in wood processing appliances, manufacturing tools, forming/shaping machines, etc., can solve the problems of high labor intensity, low production efficiency, waste of resources, etc., and achieve high transmission efficiency, low-speed torque, The effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

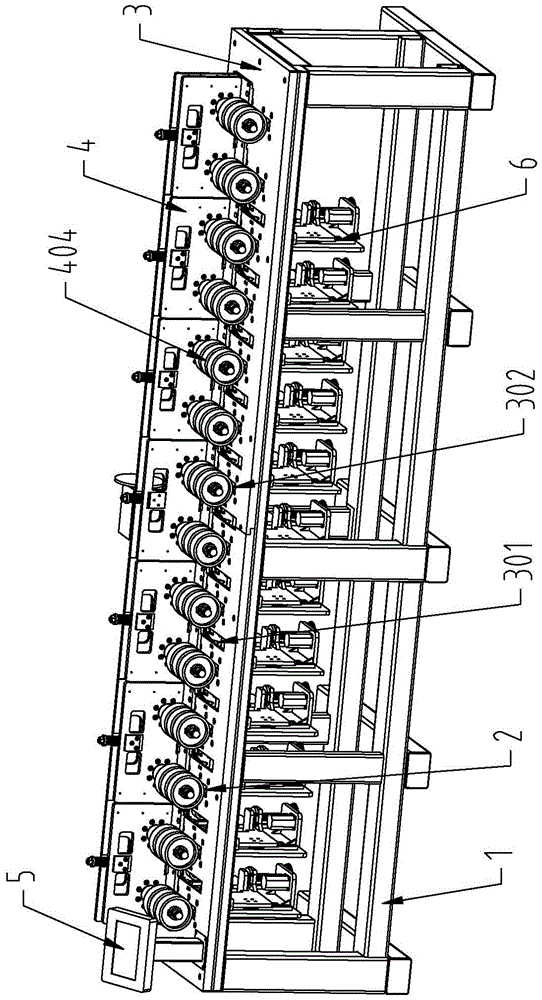

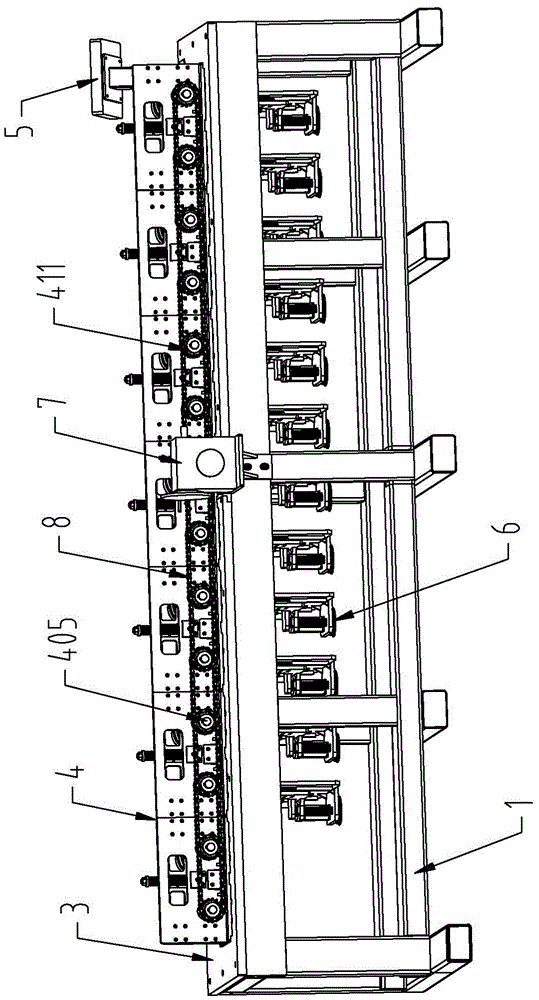

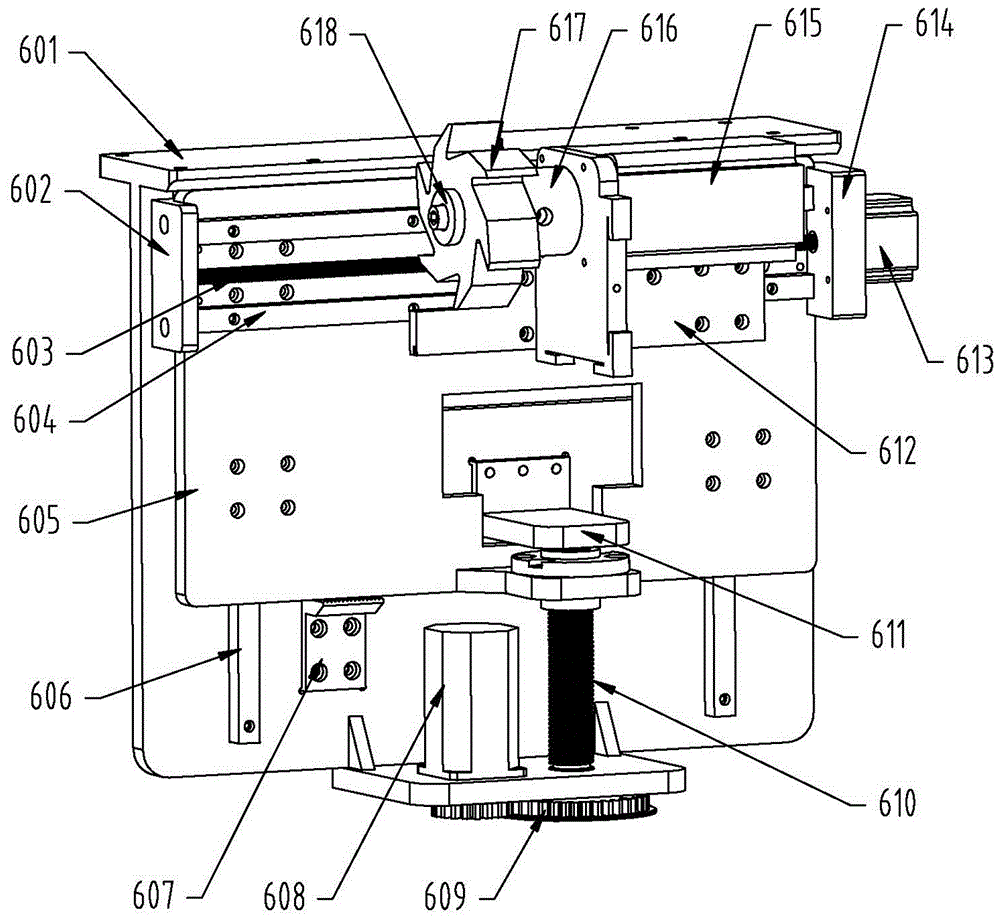

[0032] Such as Figure 1-4Shown: an antique wooden floor processing machine, including a frame 1, on which a worktable 3, a sheet material conveying device 4, a cutting device 6, a floating material device 2 and a touch screen 5 are installed, wherein the sheet material The conveying device 4 is installed on the workbench 3, the cutting device 6 and the floating material device 2 are installed under the workbench 3, and the workbench 3 is provided with a cutting groove 301 corresponding to the cutting device 6 and corresponding to the floating material device 2. Corresponding to the floating material tank 302 , the floating material tank 302 is located directly below the conveying pressing wheel 404 on the sheet material conveying device 4 , and the cutting groove 301 and the floating material tank 302 are arranged at intervals. Specifically, the cutti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap