Moistureproof wallpaper compounding equipment and moistureproof wallpaper compounding process

A technology for composite equipment and wallpaper, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of poor bonding fastness, unsatisfactory moisture-proof effect, etc., to avoid wallpaper damage, realize processing, fast and efficient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

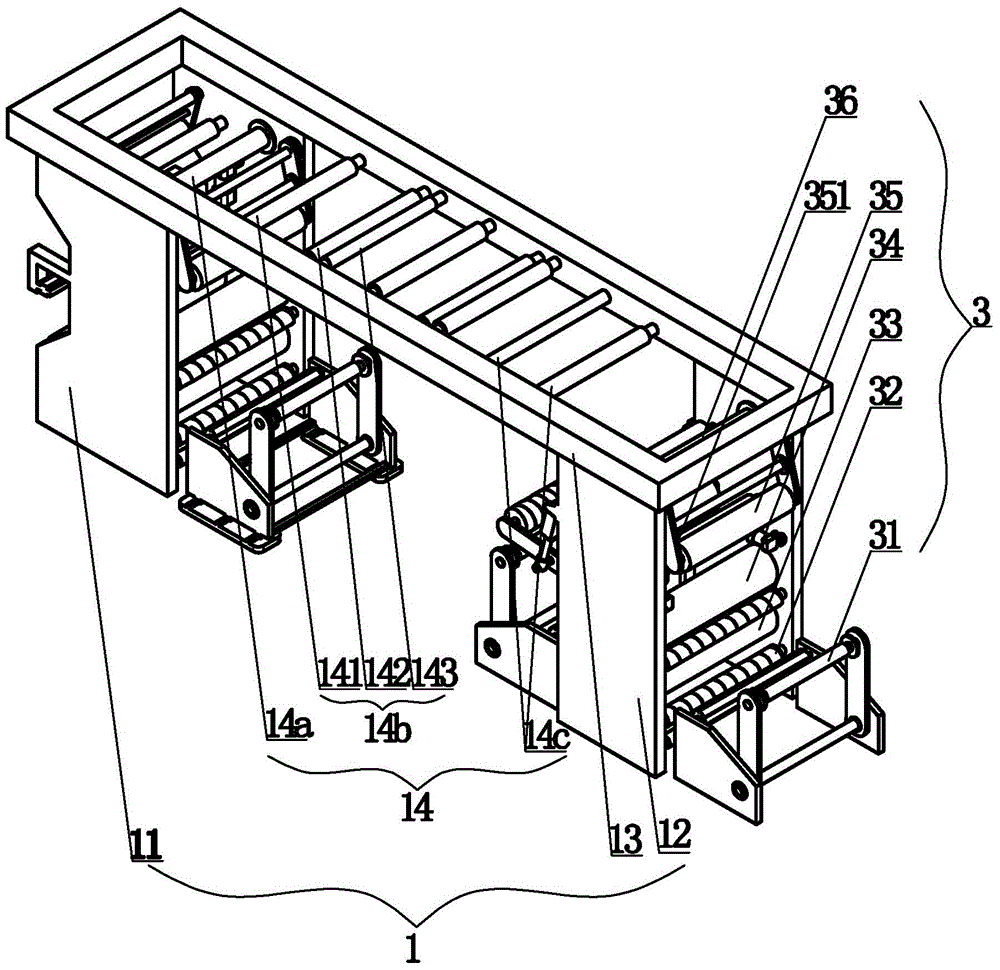

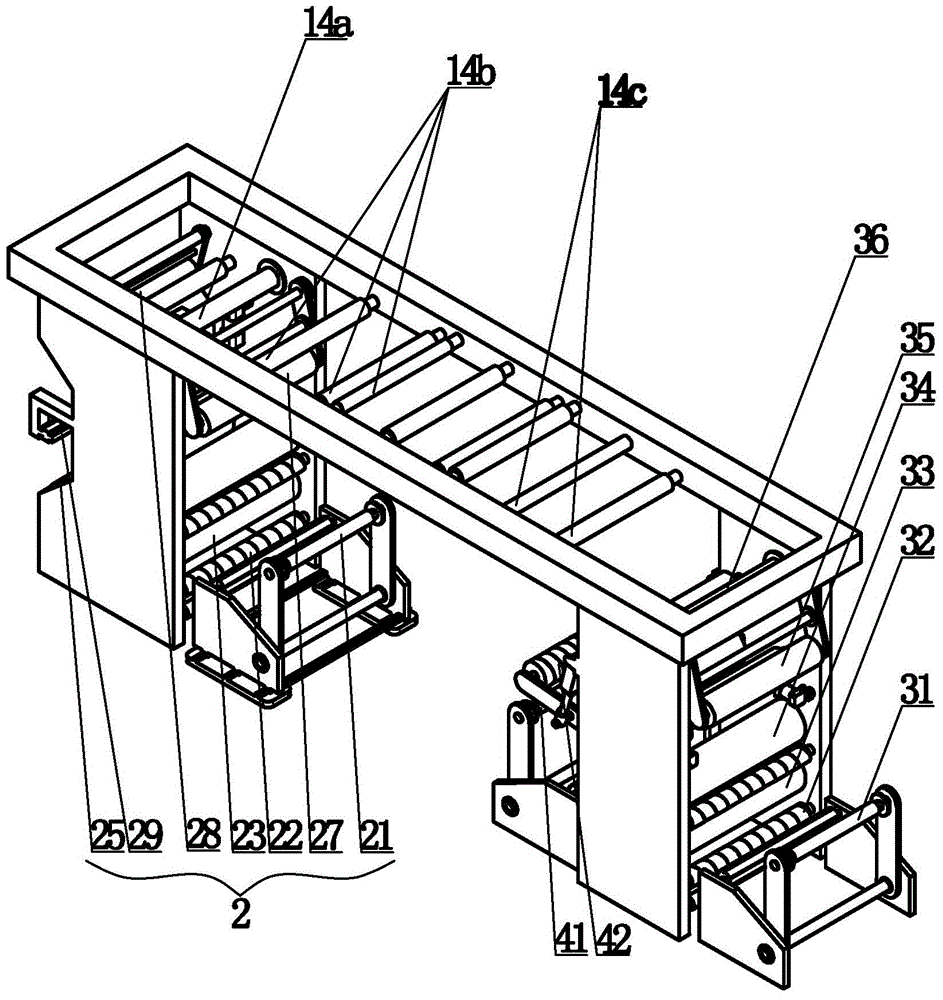

[0032] The moisture-proof wallpaper composite equipment of this embodiment, combined with figure 1 , figure 2 and image 3 , including a gantry frame 1, a cloth feeding mechanism 2, a paper feeding mechanism 3 and a composite mechanism 4, wherein the gantry frame 1 consists of a left end frame 11, a right end frame 12 and a top between the left end frame 11 and the right end frame 12. The frame 13 and the top frame 13 are arranged horizontally, and the two ends of the top frame 13 are respectively connected to the top of the left end frame 11 and the top of the right end frame 12, specifically to this embodiment:

[0033] The cloth feeding mechanism 2 is located in the left end frame 11, including feed roller 1 21, pressing roller 1 22, front drafting roller 1 23, preheating roller 1 24, rear drafting roller 1 25, rubber roller 26, pressing roller 2 27 And upper drafting roller 1 28, feed roller 1 21 is located at the outermost side; Pressure roller 1 22, front drafting rol...

Embodiment 2

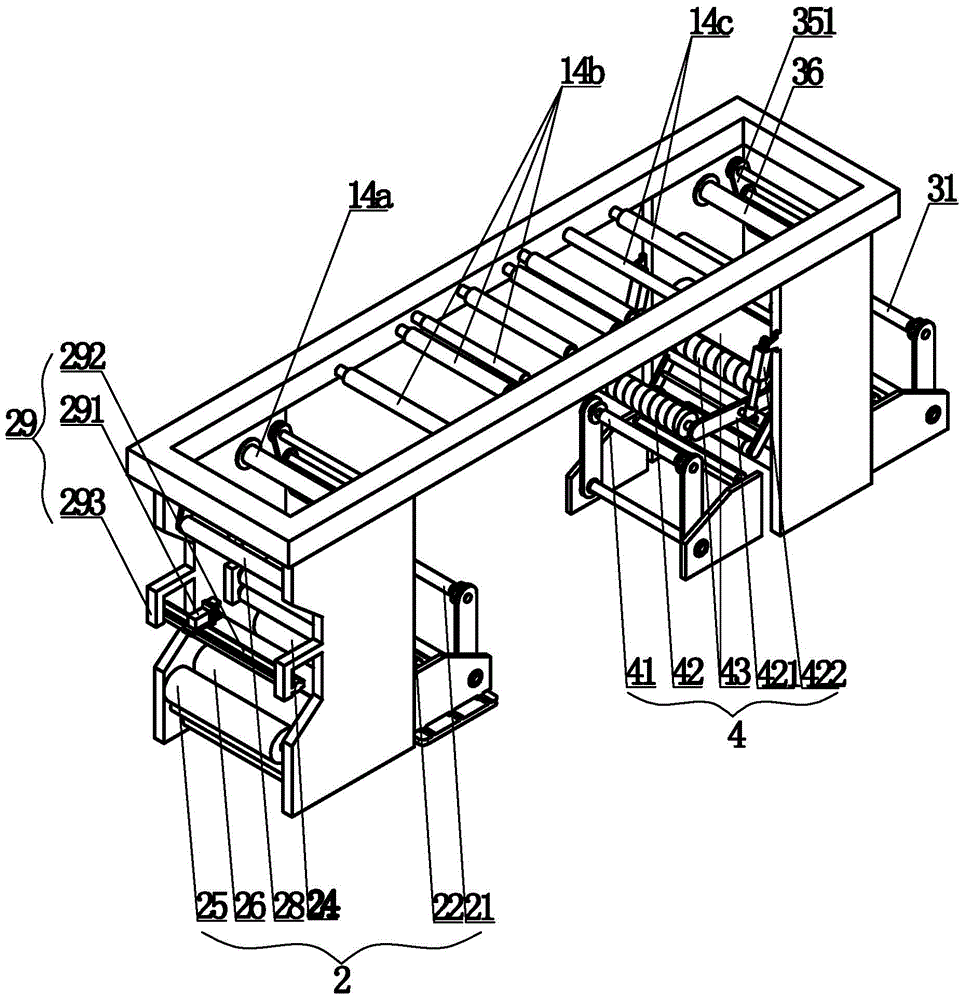

[0042] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: pressure roller two 27 is installed on the left end frame 11 through swing arm one 271; pressure roller four 35 is installed on the right end frame 12 through swing arm two 351; Also be equipped with cylinder 421 on the frame 12, the output end of cylinder 421 is connected with swing arm three 422 by rotating shaft, and pressure roller five 42 is installed on the left end frame 12 by swing arm three 422.

[0043] Pressure roller 2 27 is installed on the left end frame 12 through swing arm 1 271, and pressure roller 4 35 is installed on the right end frame 12 through swing arm 2 351. The pressure on the wallpaper can be adjusted in real time according to the actual situation of the wallpaper passing through to ensure that the wallpaper can Flat and smooth conveying; the pressure roller five 42 is installed between a pair of swing arms three 422, the swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com