Putty storage box capable of supplying material for hollow putty applying plate

A technology for scraping putty and putty boxes, which is applied in construction, building construction, etc., can solve problems such as high work fatigue, slow work progress, and inconvenience, and achieve the effects of wide application range, excellent performance, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

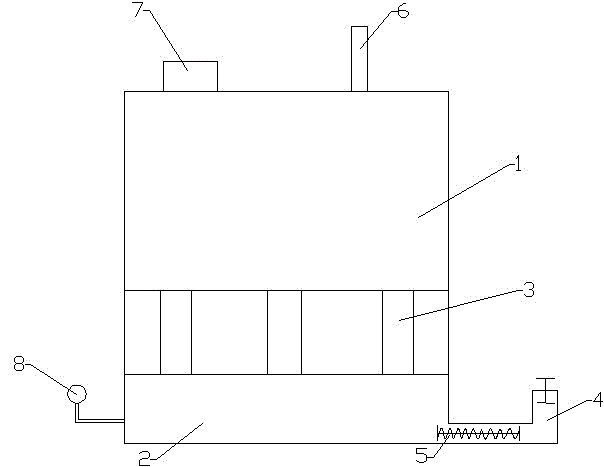

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] In the view, a putty raw material bin 1, an air pressure bin 2, and a pneumatic piston 3 are installed in a cylindrical putty box, and an air pressure gauge 8, an air pump 4, and a one-way valve 5 are installed at both ends of the putty box. The box is provided with a putty output pipe 6 and a sealable raw material feeding port 7. When in use, the putty raw material is filled in the putty raw material warehouse 1 at the sealable raw material feeding port 7, and the air pump 4 is used to pump air, and the air generated by the air pump 4 is pushed open. The one-way valve 5 enters the air chamber 2. When the pressure in the air chamber 2 reaches the specified value of the air pressure gauge 8, the air pump 4 stops pumping air, and the one-way valve 5 immediately closes the intake pipe. When the putty scraping operation starts, the air in the air chamber 2 Push the pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com