Implementation method for automatically controlling starting, stopping and exhaust amount of range hood

A technology for range hoods and implementation methods, applied in the directions of oil fume removal, heating methods, household heating, etc., can solve the problems of complicated installation and debugging process, unfavorable popularization and use, high maintenance cost, etc., and achieve low production cost, convenient debugging and calibration, Stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

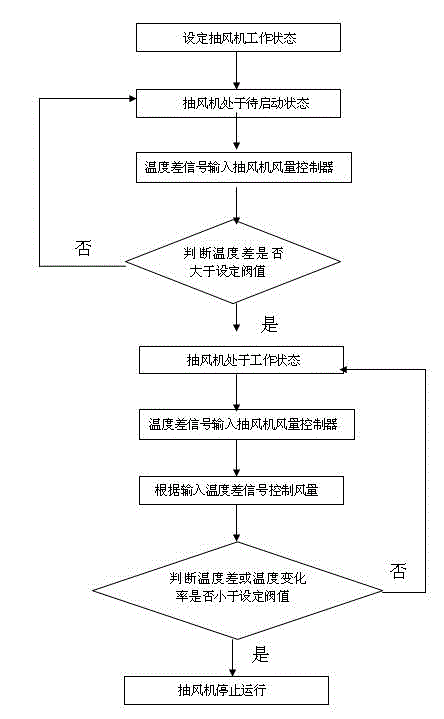

Method used

Image

Examples

Embodiment 1

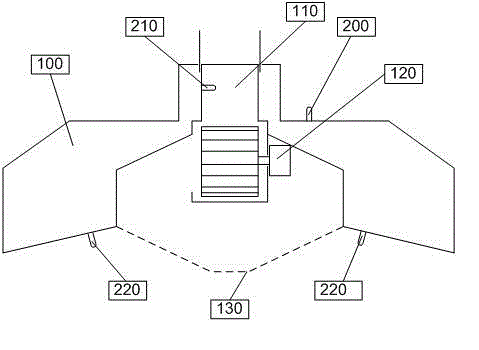

[0014] Embodiment 1: A method for realizing automatic control of start-stop and exhaust air volume of a range hood, including a smoke collection hood 100, an exhaust fan 120, an air volume controller for the exhaust fan, and a smoke exhaust pipe 110. A first temperature sensor 200, a second temperature sensor 210 is provided in the exhaust pipe 110, a third temperature sensor 220 is provided on both sides near the air inlet below the smoke collecting hood 100, and the air volume controller of the exhaust fan is based on the first temperature sensor 220. The signals of the first temperature sensor 200 , the second temperature sensor 210 and the third temperature sensor 220 determine the start and stop of the exhaust fan 120 and the air supply volume.

[0015] When the heater under the range hood is turned on, the temperature between the range hood and the heater rises, and the temperature values T1 and T1a measured by the two third temperature sensors 220 and the temperature v...

Embodiment 2

[0021] Embodiment 2: basically the same as Embodiment 1, the difference is that when the heater under the range hood is turned on, the temperature between the range hood and the heater rises, and the temperatures measured by the two third temperature sensors 220 respectively There is a temperature difference ΔT12=T1-T2, ΔT12a=T1a-T2 between the values T1, T1a and the temperature value T2 measured by the first temperature sensor 200. If ΔT12 or ΔT12a is greater than the threshold value of 1.0 degrees Celsius, the exhaust fan 120 starts to run.

[0022] After the exhaust fan 120 is running, if ΔT13 and ΔT13a are less than the threshold value of 1.0 degrees Celsius, and dT1 / dt or dT1a / dt (temperature change rate) is less than 0.1 degrees Celsius / second, and the temperature difference between T1, T1a and T2 is close to or less than 1.0 degrees Celsius , the exhaust fan 120 stops running.

Embodiment 3

[0023] Embodiment 3: basically the same as Embodiment 1, the difference is that when the heater under the range hood is turned on, the temperature between the range hood and the heater rises, and the temperatures measured by the two third temperature sensors 220 respectively There is a temperature difference ΔT12=T1-T2, ΔT12a=T1a-T2 between the values T1, T1a and the temperature value T2 measured by the first temperature sensor 200. If ΔT12 or ΔT12a is greater than the threshold value of 0.75 degrees Celsius, the exhaust fan 120 starts to run.

[0024] After the exhaust fan 120 is running, if ΔT13 and ΔT13a are less than the threshold value of 0.75 degrees Celsius, and dT1 / dt or dT1a / dt (temperature change rate) is less than 0.075 degrees Celsius / second, and the temperature difference between T1, T1a and T2 is close to or less than 0.75 degrees Celsius , the exhaust fan 120 stops running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com