Calibration method for measuring accuracy of high-temperature crack length through direct current potential method

A technology of crack length and direct current potential, which is applied in the direction of measuring devices, electric devices, electromagnetic means, etc., can solve the problems of crack length inaccuracy, sample surface oxidation, blackening, etc., and achieve the effect of convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

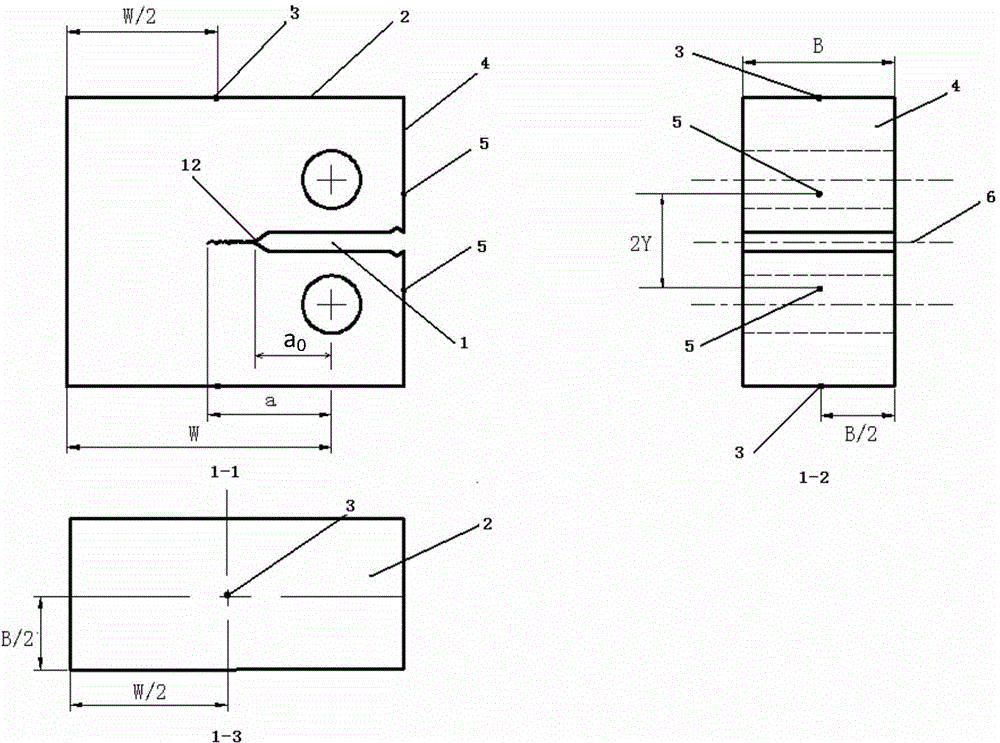

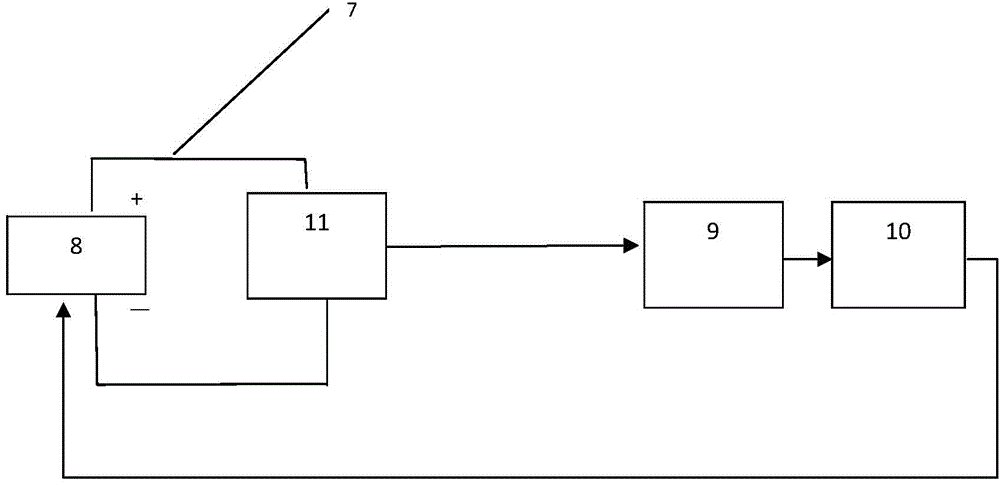

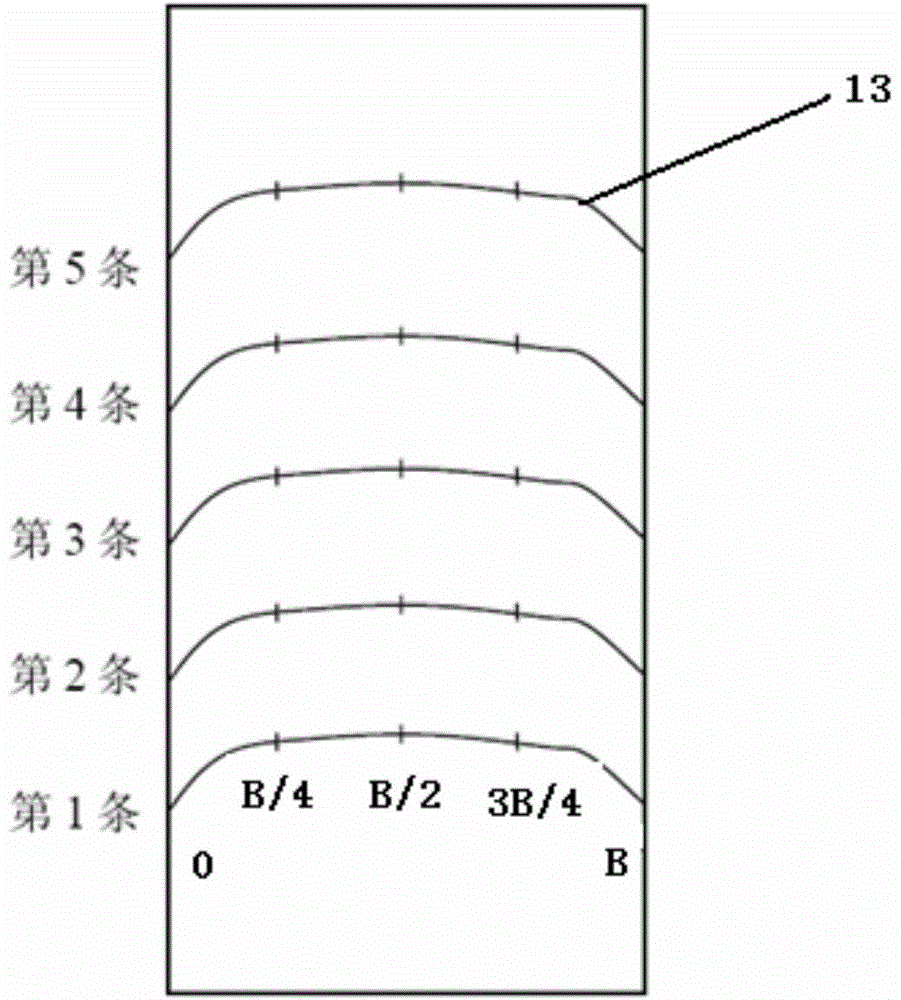

[0028] See attached Figure 1~3 As shown, this kind of calibration method for measuring the precision of high-temperature crack length by DC potentiometric method is characterized in that: the steps of the method are as follows:

[0029] Step 1. Referring to the requirements of the navigation mark HB7680-2000, process a compact tensile calibration sample 11. The material grade of this sample is a nickel-based superalloy of GH4169G. The width W of the sample is 40 mm, and the thickness B of the sample is Mark a current input solder joint position 3 on the sample width surface 2 on both sides of the notch 1 of the calibration sample 11, and the current input solder joint position 3 is in the center of the sample width W and sample thickness B, namely The position of the current input solder joint (3) is 20mm and 5mm from the edge of the sample width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com