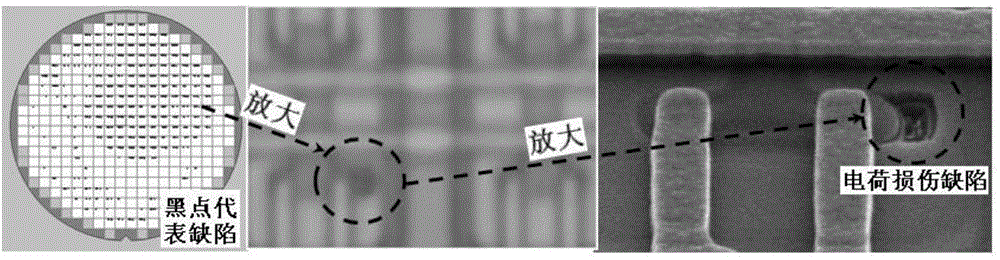

Method for detecting electric charge damage in photolithography technique

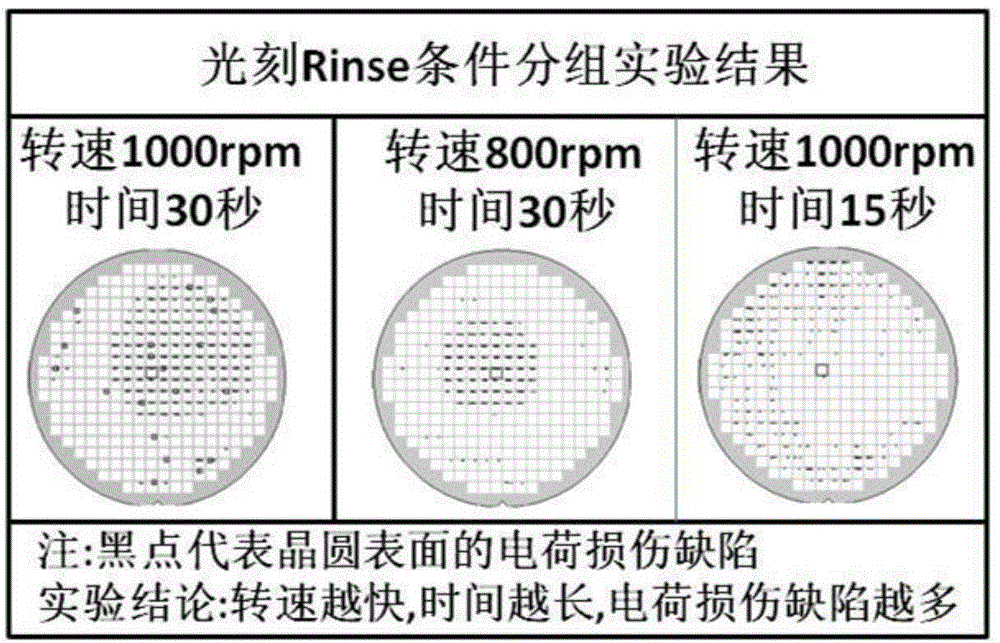

A lithography process and a technology for detecting light, which are applied in microlithography exposure equipment, photolithography exposure devices, circuits, etc., can solve problems such as poor chemical reagent spit, excessive wafer speed, and reliability risks. Achieve convenient and timely effective charge damage, improve yield and reliability, and optimize photolithography process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0034] The invention discloses a method for detecting charge damage in a photolithography process. The method can be applied to a semiconductor process followed by a wet process after photolithography. The method specifically includes the following steps:

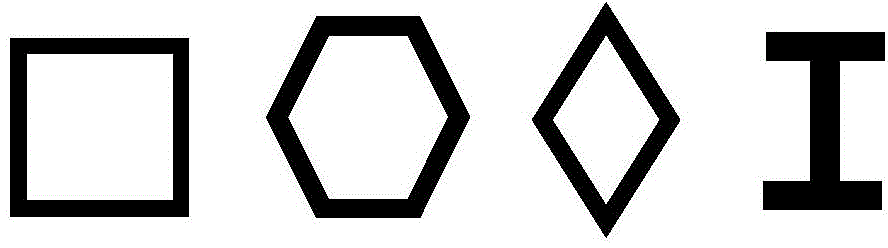

[0035] Step 1: When designing the product layout, place the detection pattern in the chip or dicing groove (the detection pattern can be placed in the chip (affecting wafer utilization, not recommended), or in the dicing groove (recommended) ). The detection pattern is given by image 3 Cell arrays consisting of repeating arrangements of detection cells are shown, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 shown. The unit structure of the detection figure can be a circle, an I-shape, or a polygon. Such as image 3 As shown, the unit structure of the detection pattern ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap