Identify defects in the function of at least one active switching element of an active bridge rectifier

A technology of bridge rectifier and active switch, which is applied in the direction of electrical components, output power conversion devices, AC power input conversion to DC power output, etc., which can solve problems such as high temperature and reduced efficiency, and achieve load reduction, Avoid the effect of the vehicle operating point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

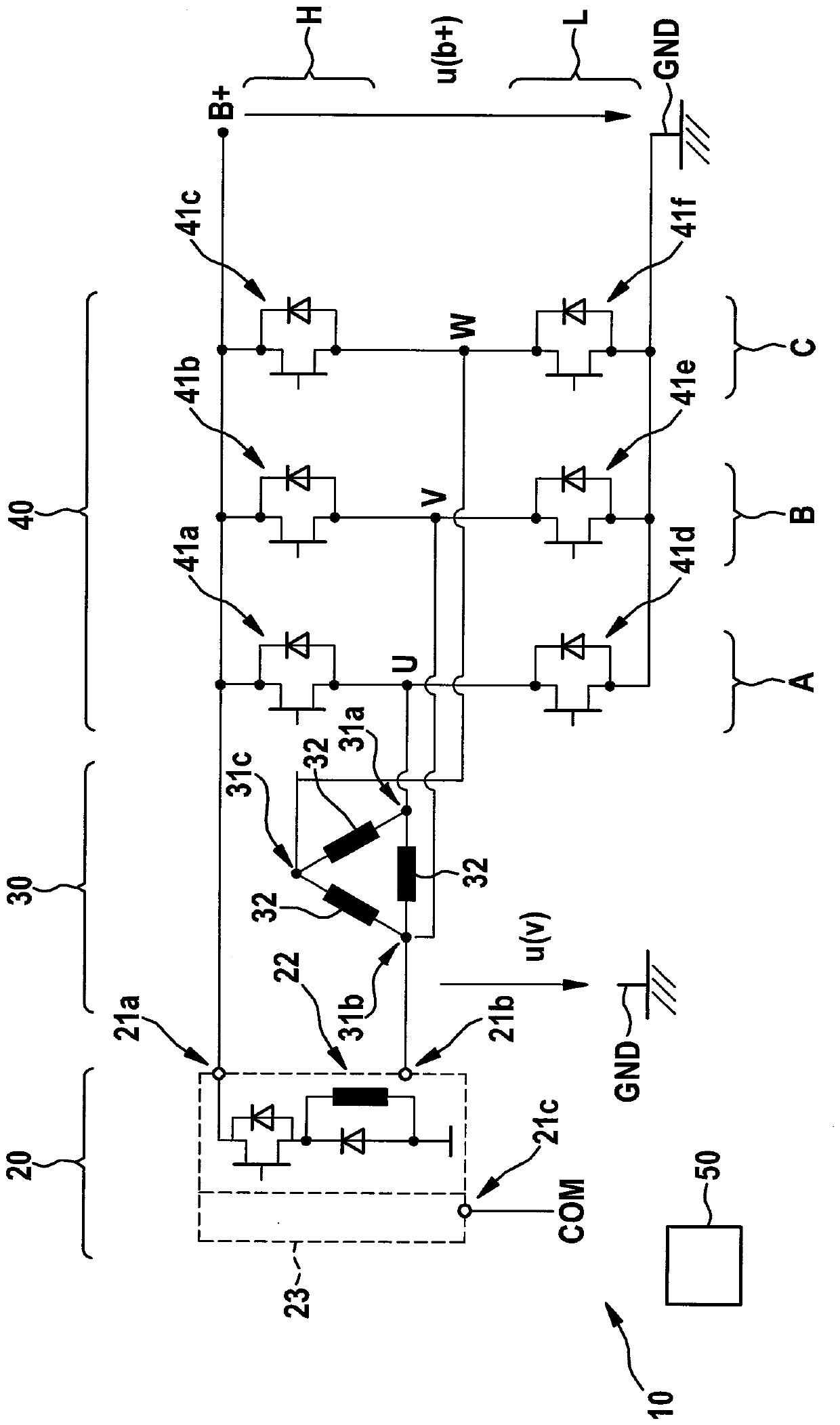

[0037] exist figure 1 A device with generators 20 , 30 , bridge rectifier 40 and control device 50 is schematically shown in FIG. 3 using the example of a three-phase system. The described arrangement is part of the on-board electrical system 10 of the motor vehicle, which is only partially shown here.

[0038]The generator 20, 30 comprises a generator regulator 20 with terminals 21a, 21b and 21c, a field coil 22 and a communication line COM and a stator with three stator windings 32 interconnected in a delta circuit at switching points 31a, 31b and 31c 30.

[0039] bridge rectifier 40 in figure 1 is shown as a six-pulse bridge rectifier 40 which is provided for rectifying the rotating current of the three-phase generator 20 , 30 . In the same way, however, it is also possible, for example, to use four-phase, five-phase, six-phase or seven-phase generators 20 , 30 and to use correspondingly adapted eight-pulse, twelve-pulse or fourteen-pulse bridge generators. Rectifier 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com