Separation device for flue gas and perfusate

A separation device and perfusate technology, applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve occupational hazards, fatigue, discomfort and other problems, achieve the effect of easy cleaning and management, and increase the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

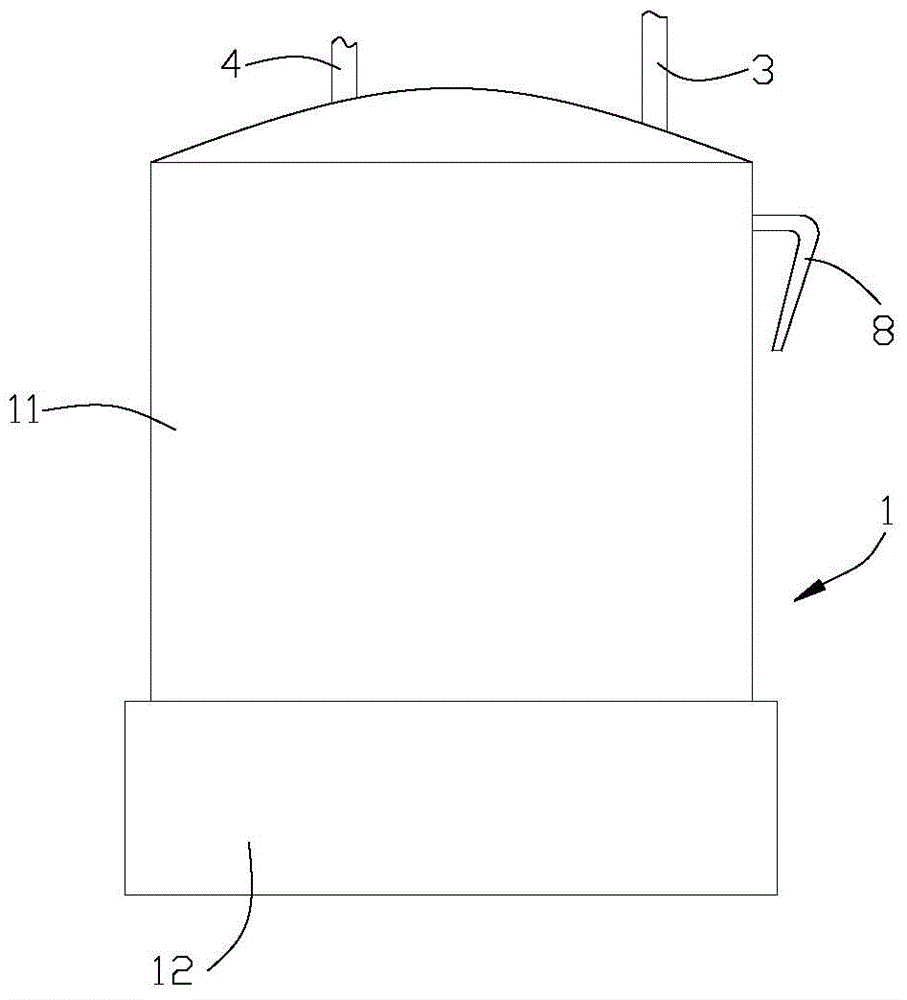

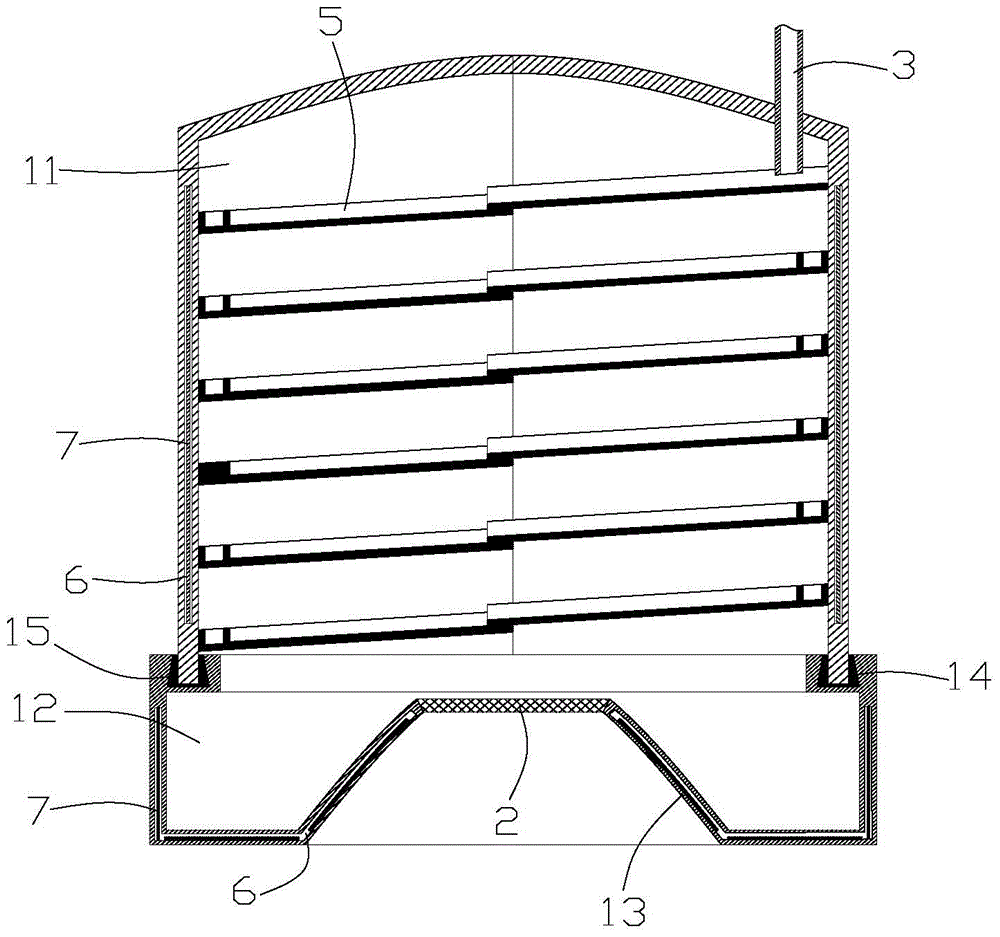

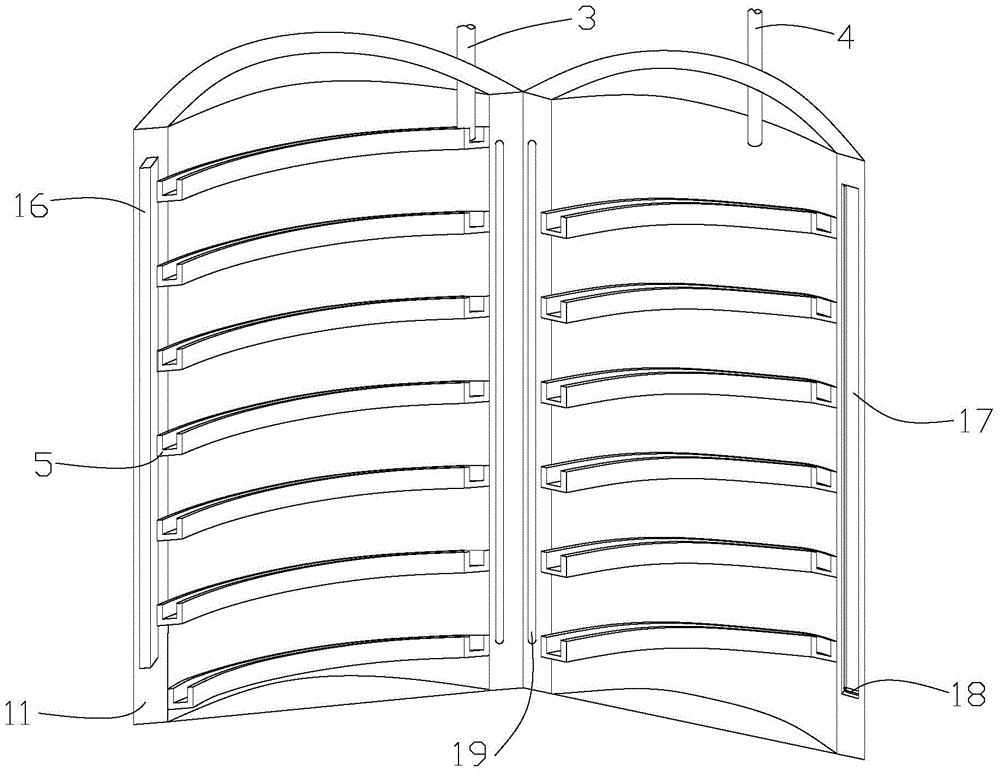

[0018] Combine below figure 1 , figure 2 , image 3 The separation device for flue gas and perfusate of the present invention includes a columnar separation chamber 1 with an inner cavity, the top end of which is closed, and a filter screen 2 is installed at the bottom end. A collection pipe 3 for smoke and perfusate, which is sealed and connected to the outlet port of the resectoscope sheath, and a negative pressure pipe 4 is provided at the top, and the negative pressure pipe is connected with the negative pressure machine in the operation center; A U-shaped liquid guide groove 5 is arranged spirally from top to bottom, the upper end of the liquid guide groove communicates with the collection pipe, and the lower end of the liquid guide groove is close to the filter screen. The mixture of flue gas and perfusate from the resectoscope sheath enters the liquid guide groove through the collection tube, so that the mixture flows spirally along the peripheral wall of the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com