Method for realizing bundled plastic film with single heat-sealing joint in plastic sealing pre-bundling process

A plastic film and process technology, applied in the field of financial equipment control, can solve problems such as uneven interfaces and loose bundles, and achieve the effects of neat joints, reduced downtime failure rate, and improved strapping efficiency and machine stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

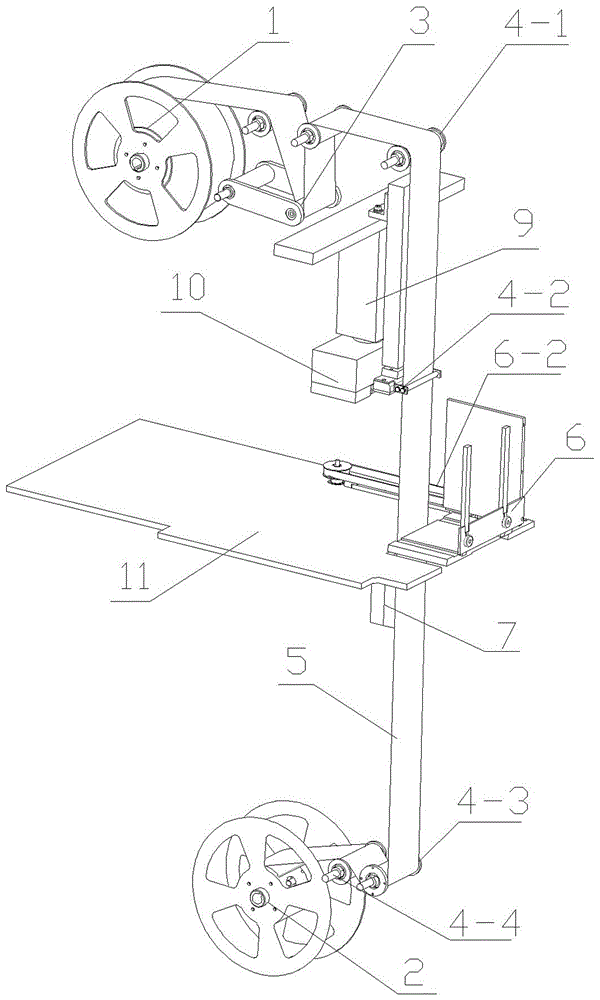

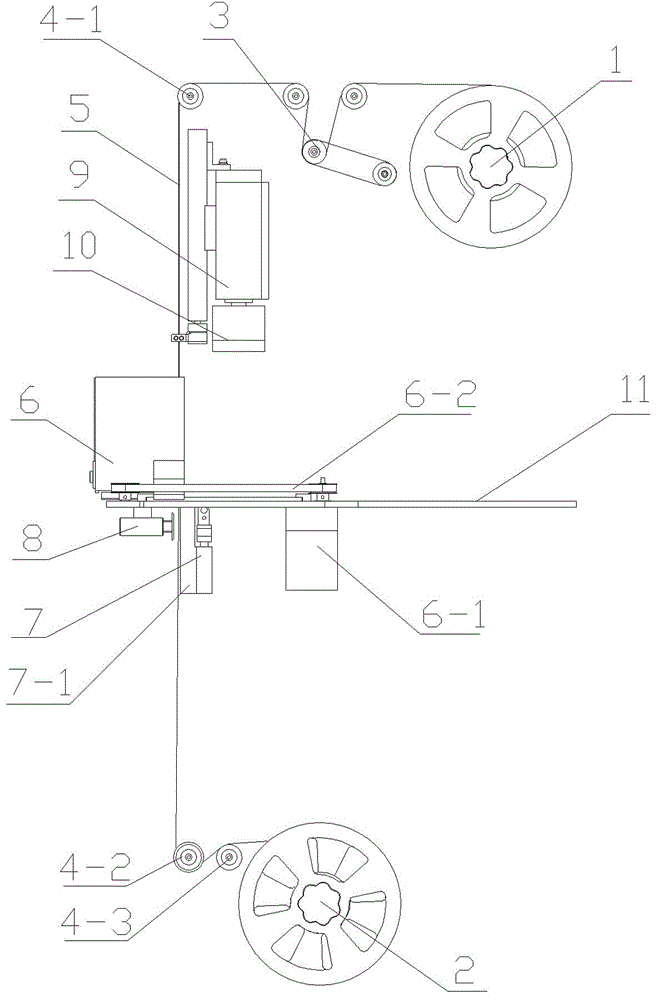

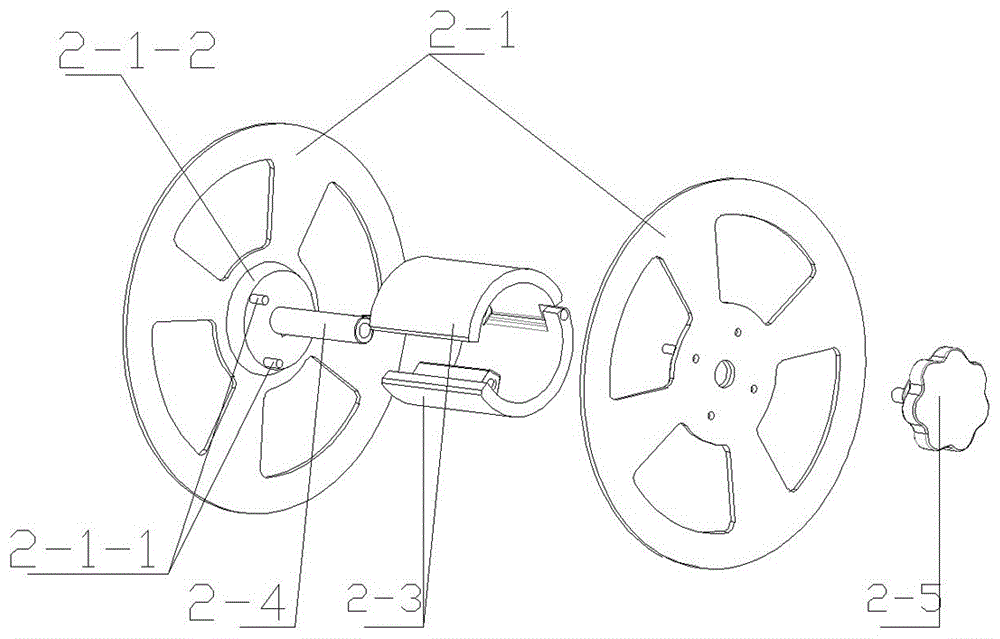

[0022] The realization of the method of the present invention is based on the pre-binding mechanism composed of the plastic film rack 1, the waste film rack 2 and their supporting driving mechanisms, the pushing device 6 of the banknote pile, the embedded roller pressing head 10 and the sealing and cutting device. see figure 1 and figure 2 , which is a specific embodiment of the present invention to realize that the bundled plastic film has a single heat-sealing joint, and its structure includes a plastic film rack 1 arranged above and a supporting drive motor, and a waste film rack 2 arranged below and a supporting drive motor , between the plastic film frame 1 and the waste film frame 2, a tension mechanism 3, an upper correction roller 4-1, a film limiting assembly 4-2, a lower correction roller 4-3 and a film guide roller 4-4 are arranged in sequence, embedded The rolling head 10 and the linear drive mechanism 9 for driving it to move up and down, as well as the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com