Method for improving complexity of fracture and construction efficiency of horizontal well

A technology with high construction efficiency and horizontal wells, which is applied in the field of oil and gas field exploration and development, and can solve the problems of small drainage volume and low complexity of fracturing fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

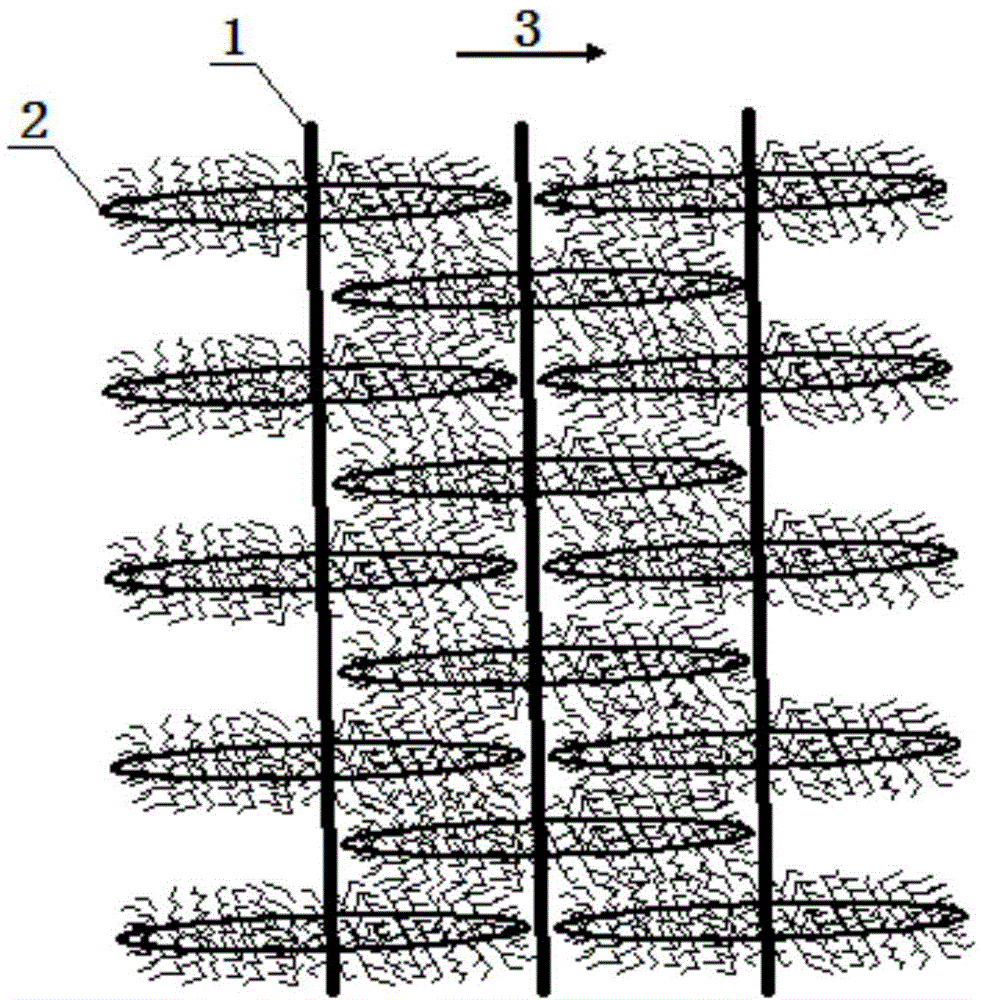

[0011] 1. Deployment of horizontal wells

[0012] Three horizontal wells are deployed on the same well site, and each adjacent wellbore 1 is parallel to each other, and each wellbore 1 is perpendicular to the maximum principal stress direction 3 of the formation;

[0013] 2. Select the location of the perforation section

[0014] The perforation section position of each horizontal well (that is, the fracture initiation site) and the perforation section position of another adjacent well are arranged alternately, and the interval between the fracturing sections of each well is set between 100 and 150 meters.

[0015] 3. Hydraulic fracturing

[0016] Use a set of fracturing units to fracture the first section of the first well with a displacement of 4.0m3 / min, then immediately fracture the first section of the adjacent well, and so on, successively alternately fracture the two adjacent wells .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com