Paste Concentrator

A thickening machine and paste technology, which is applied in the sedimentation tank, the feeding/discharging device of the sedimentation tank, chemical instruments and methods, etc., can solve the problems of small torque of the transmission system, low concentration height of the thickening equipment, and inability to operate the slurry. , to achieve the effect of accurate distance, large torque and satisfying filling needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

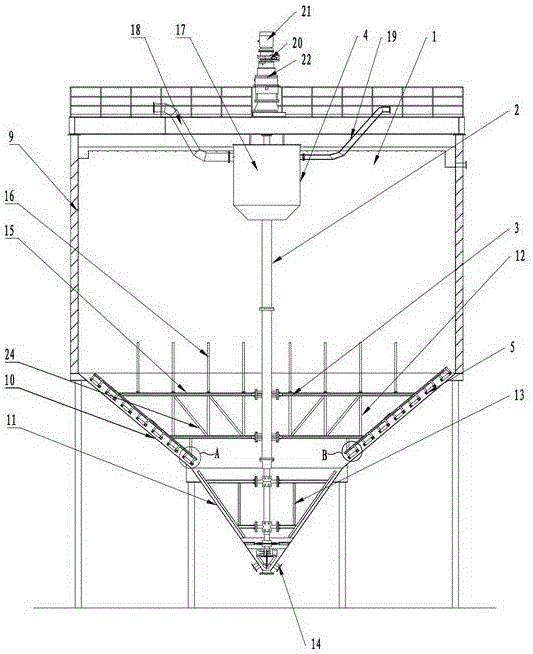

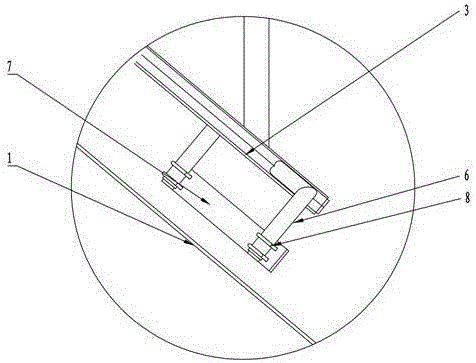

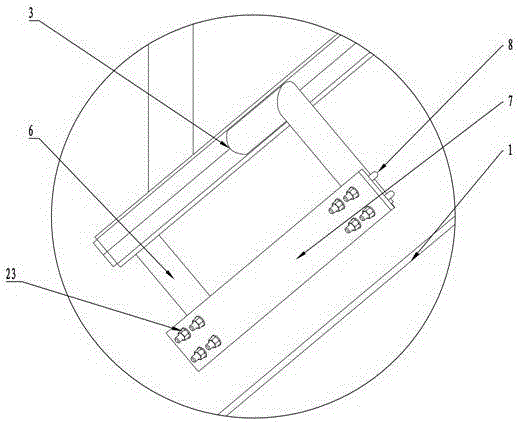

[0023] Such as Figure 1 to Figure 4 The paste concentrator shown is mainly composed of a pool body 1, a feeding device 4, a main shaft 2, a rake frame 3, a rake tooth 5 and a driving device for driving the main shaft 2 to rotate; the height of the pool body 1 is 8-10 m, the compression height of the concentrator in this embodiment is increased from 3 to 4 meters to 8 to 10 meters. On the one hand, the residence time of the ore pulp in the concentrator is prolonged, and the efficiency of solid-liquid separation is improved. On the other hand, the compression The increase in height also increases the pressure on the pulp, which is beneficial to the separation of water and solids in the pulp. In this embodiment, the feeding device 4 is installed on the upper part of the pool body 1; the rake teeth 5 are connected to the main shaft 2 through the rake frame 3; the rake teeth 5 include a steel pipe 6 fixed on the rake frame 3, a rectangular steel plate 7 and U-shaped bolts 8. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com