Patents

Literature

43results about How to "Meet filling needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

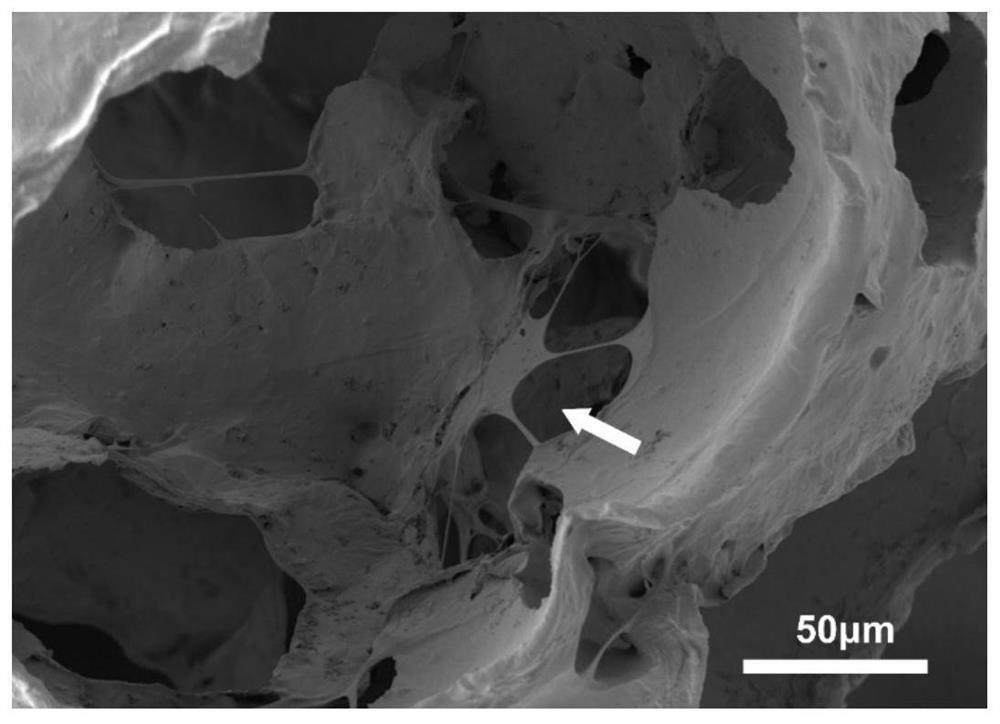

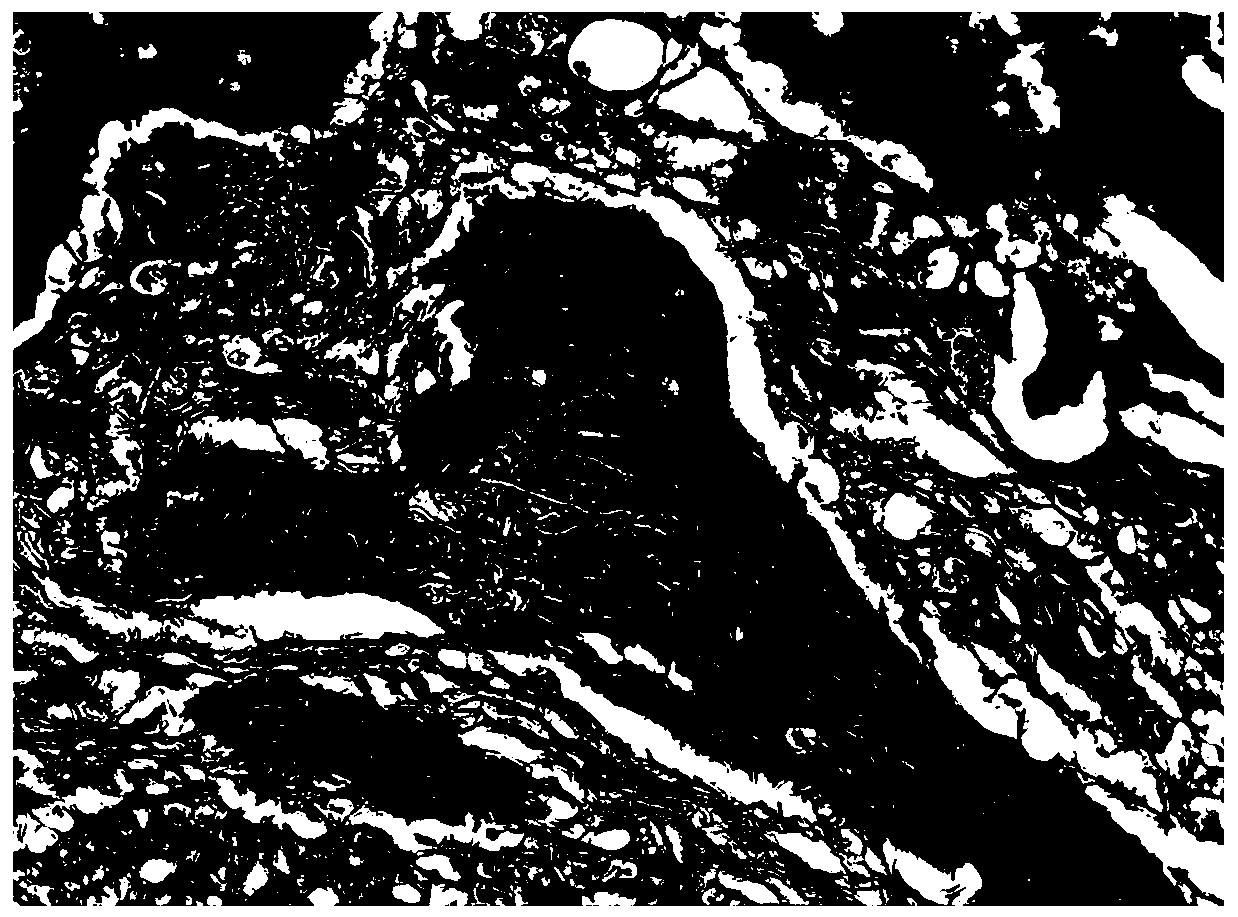

Fiber-based three-dimensional porous composite material for bone repair and preparation method thereof and molded product

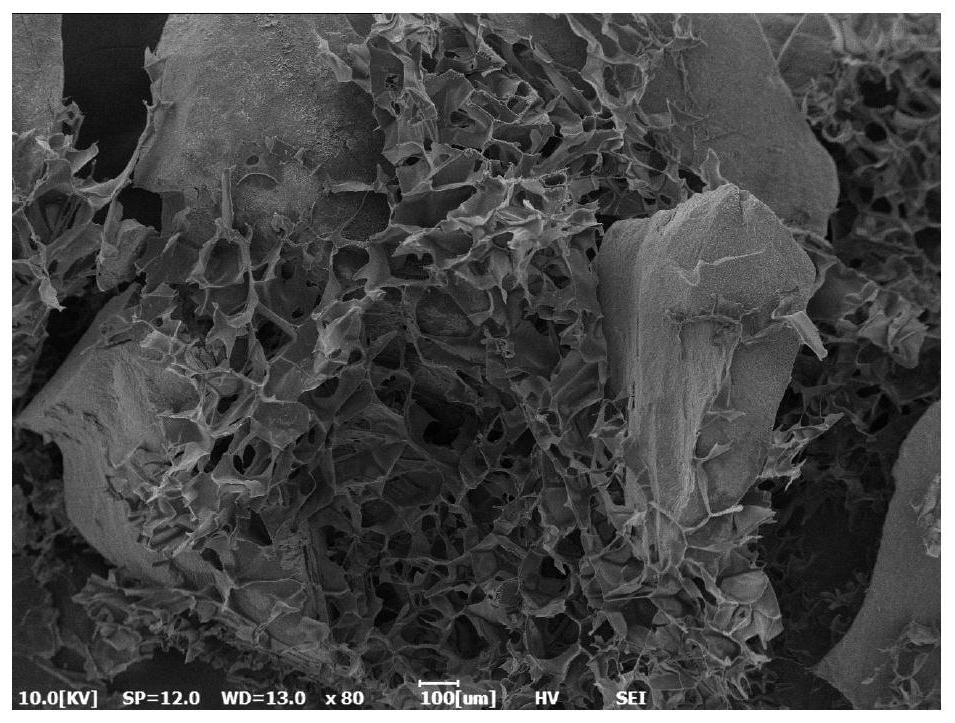

ActiveCN107137773AWell filled demandMeet filling needsTissue regenerationProsthesisFiber structurePorous composite

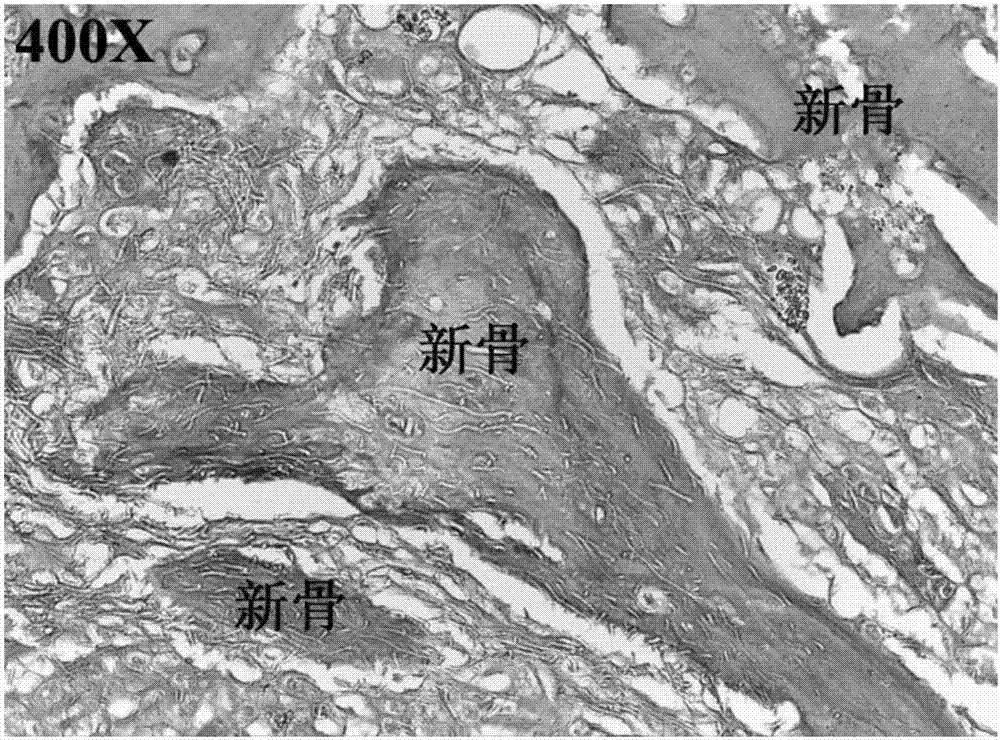

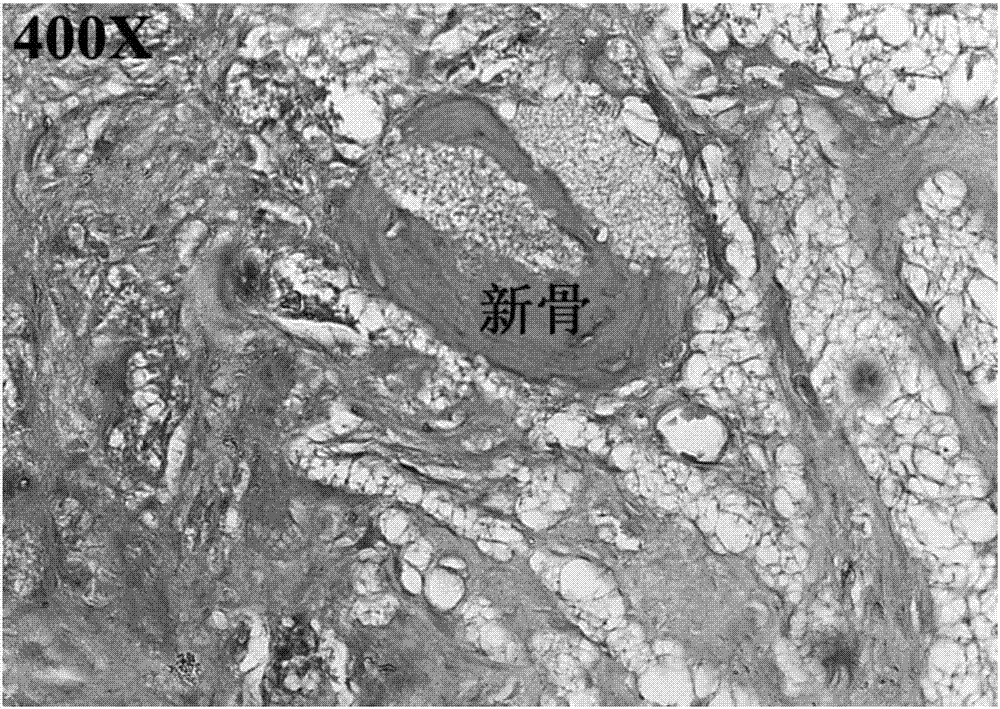

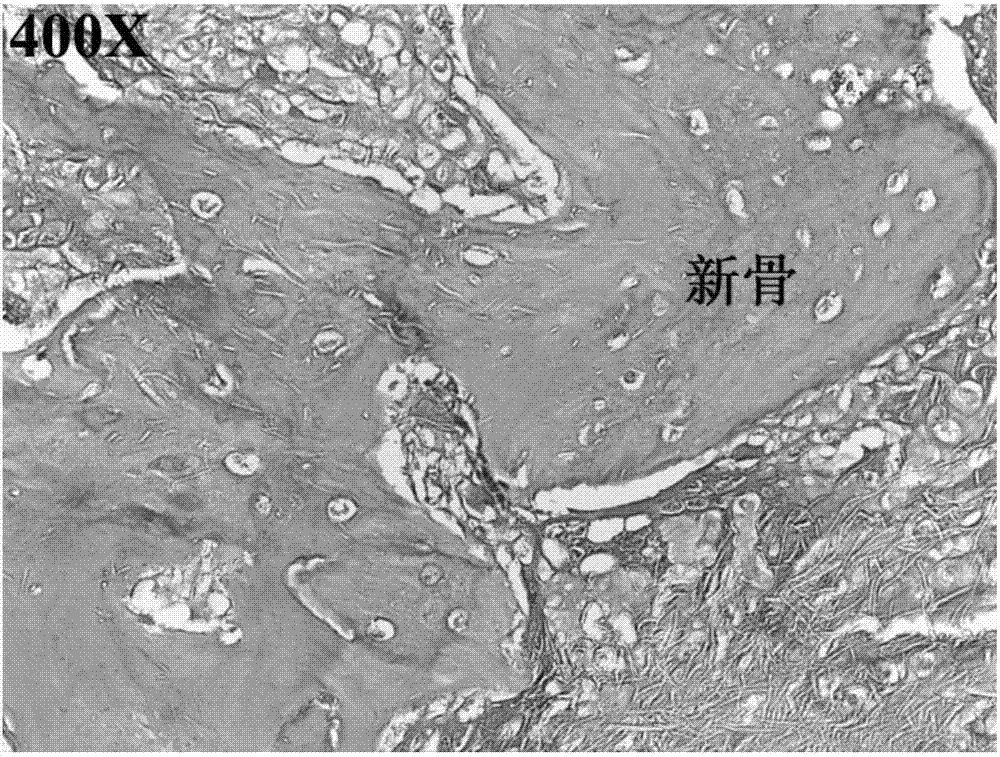

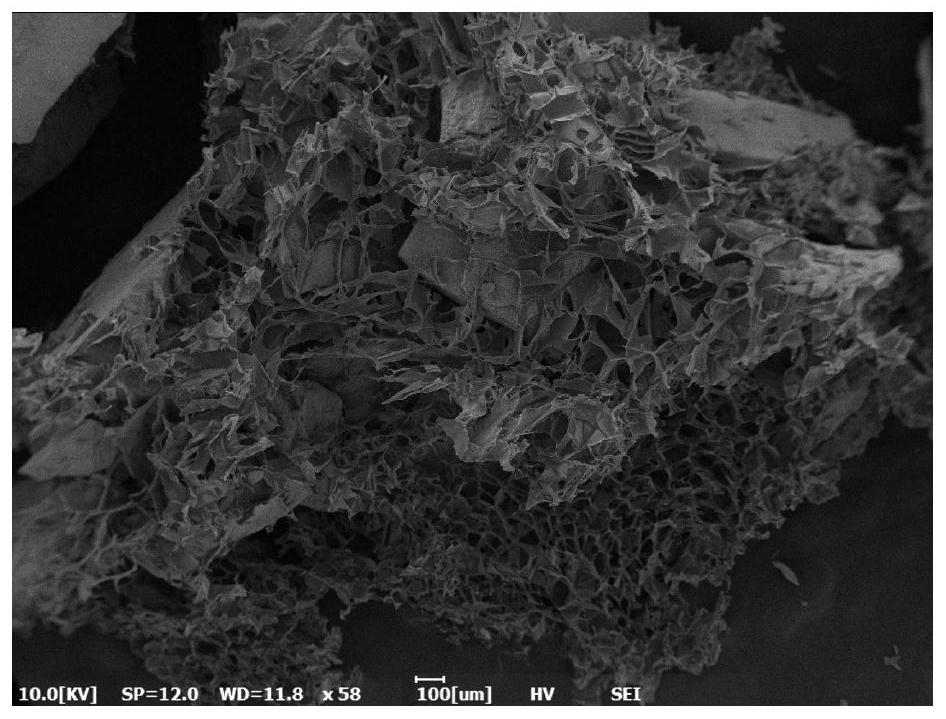

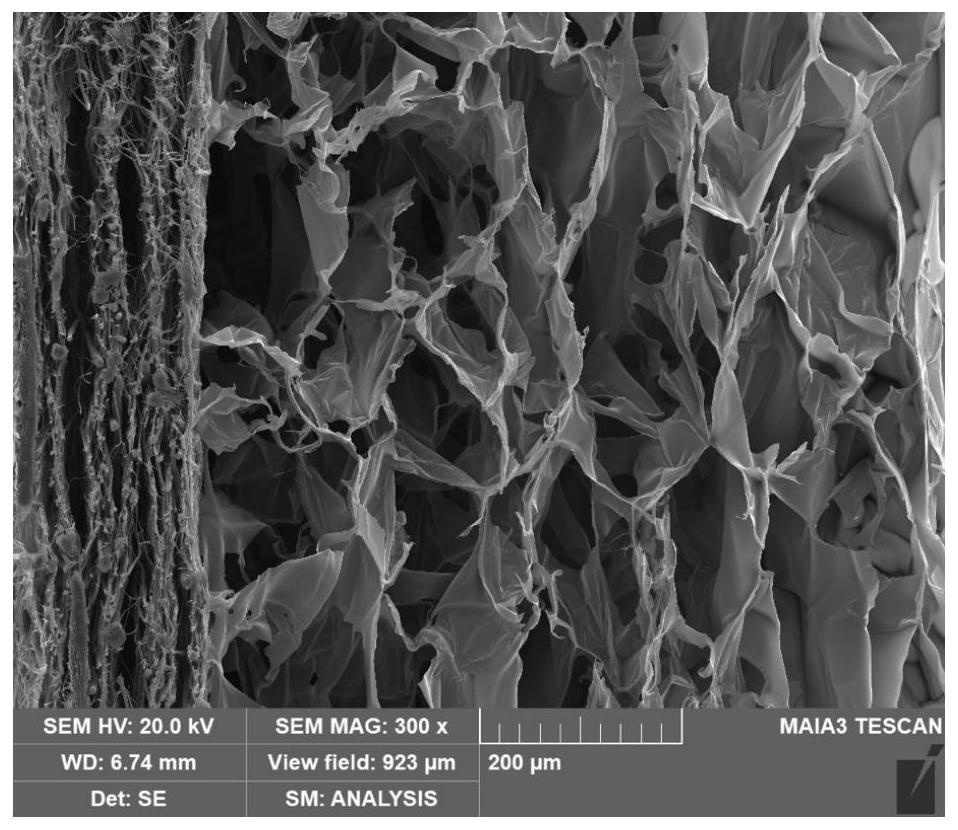

The invention provides a fiber-based three-dimensional porous composite material for bone repair and a preparation method thereof and a molded product. The fiber-based three-dimensional porous composite material comprises micronano fiber powder and a binder, wherein the particle diameter of the micronano fiber powder is 10-500 micrometers, the diameter of fiber forming the micronano fiber powder is 0.1-100 micrometers, and the micronano fiber powder is evenly dispersed in the binder; the binder comprises biodegradable and self-curable inorganic components; the fiber-based three-dimensional porous composite material comprises, by mass, 5-50% of the micronano fiber powder, the porosity of the fiber-based three-dimensional porous composite material is 30-85%, and the compressive strength is 1-15 MPa. A constructed fiber-based three-dimensional connected porous scaffold is simple in preparation method and has a micronano fiber structure, so that the scaffold has a remarkable induced osteogenesis effect; the constructed fiber-based three-dimensional connected porous scaffold can better meet the filling demand of bone defect sites and can provide better mechanical properties.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH +1

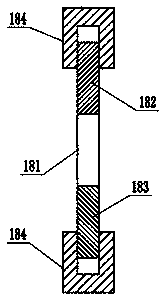

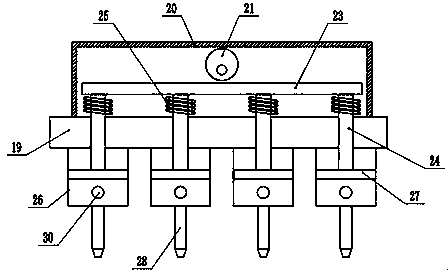

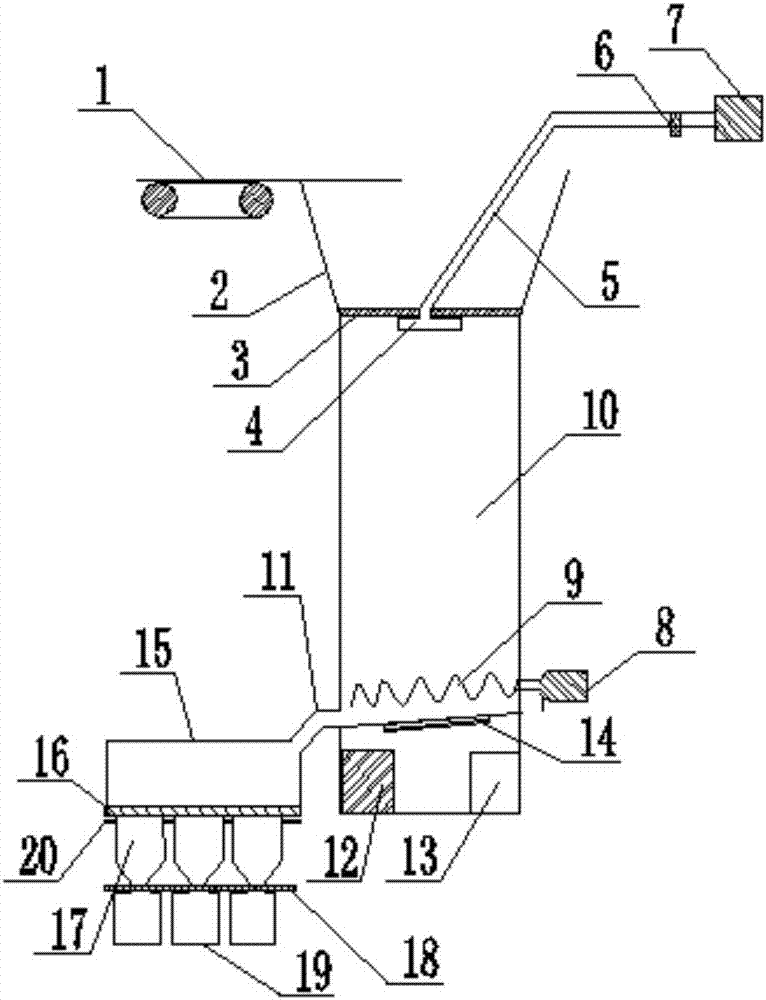

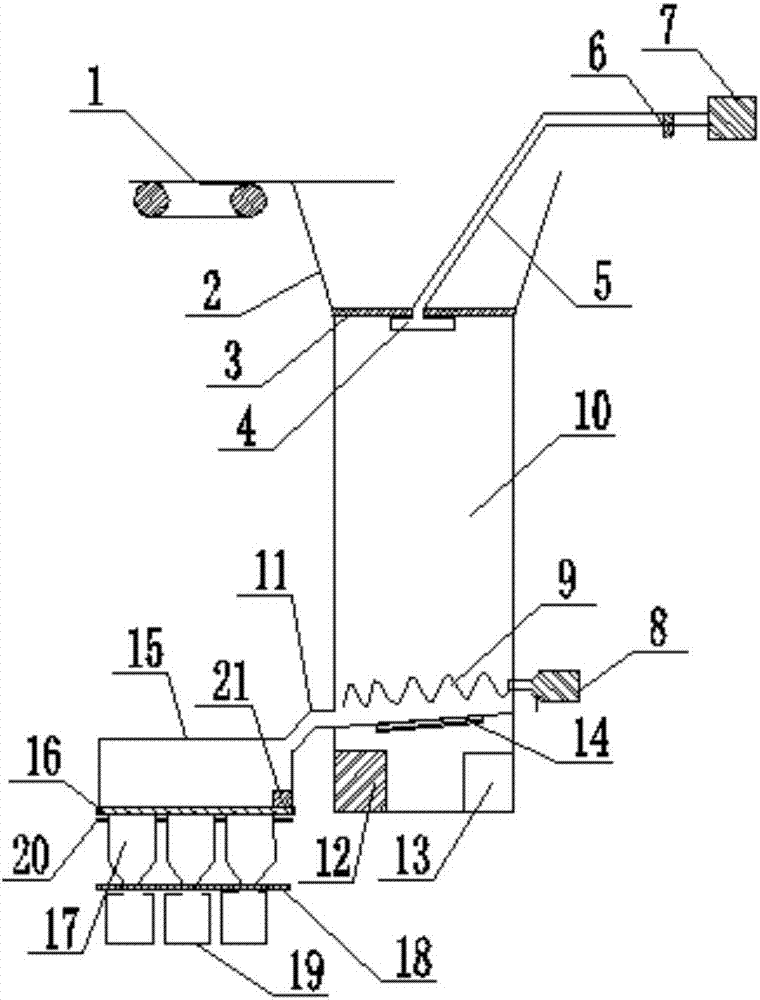

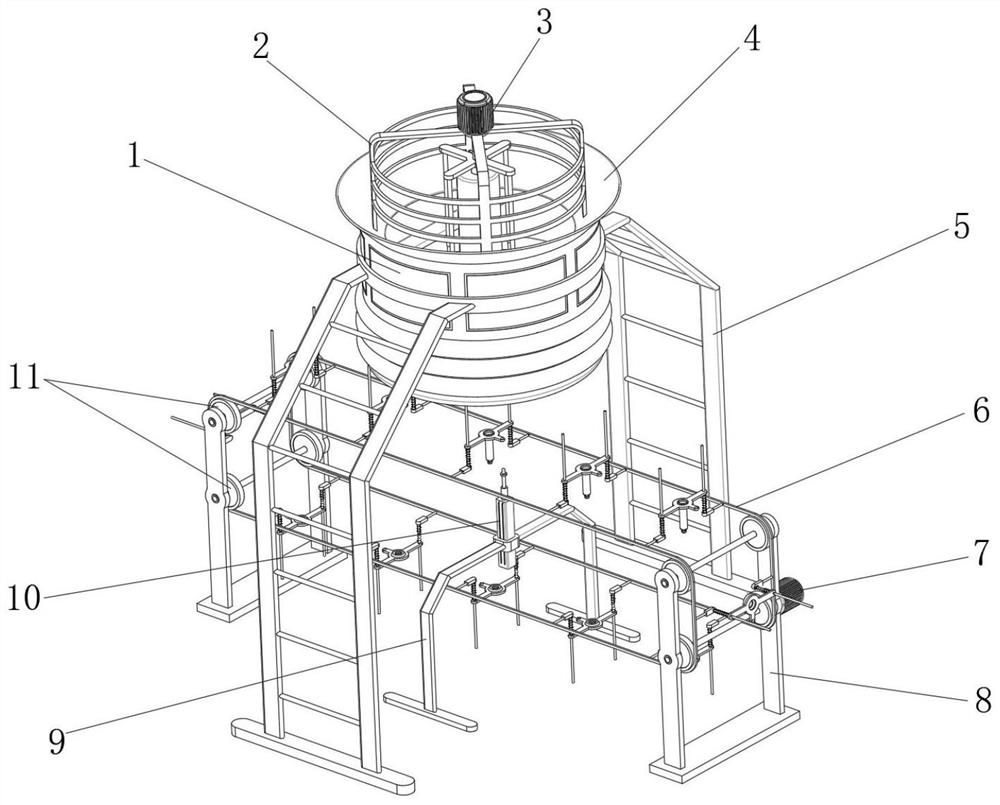

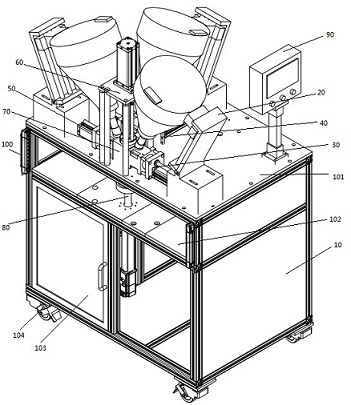

Multi-station simultaneous quantitative filling device for bread processing

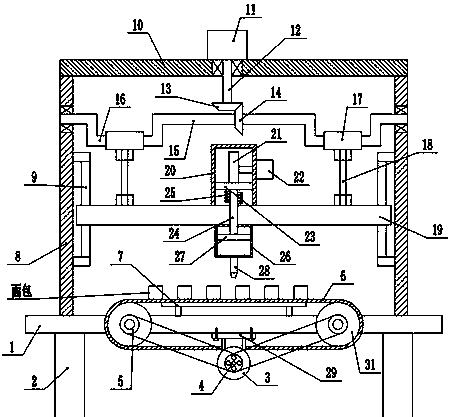

InactiveCN108633947AReasonable structureInnovative designDough processingEngineeringUltimate tensile strength

The present invention discloses a multi-station simultaneous quantitative filling device for bread processing. The multi-station simultaneous quantitative filling device comprises a base seat. Supportframes are arranged on both sides of the upper end of the base seat; a top plate is arranged on the top end of the support frames; a first rotating shaft is arranged at the middle part of the top plate; the middle part of the lower end of the first rotating shaft is connected with a first gear; the lower end of the first gear is meshed with a second gear; the middle part of the second gear is connected with a second rotating shaft; the middle parts of both ends of the second rotating shaft are connected with cranks; the middle part of the crank is connected with a rotating sleeve; the lower end of the rotating sleeve is connected with a lifting adjusting device; the lower ends of the lifting adjusting devices are connected with a lifting plate; the middle part of the upper end of the lifting plate is provided with a driving box; the driving box is internally provided with a pressing plate; the upper end of the pressing plate contacts with a pressing wheel; the middle part of the lowerend of the pressing plate is connected with a pressing shaft; and the lower end of the pressing shaft passes through the lifting plate and connected with a piston. The multi-station simultaneous quantitative filling device realizes the up and down movement of the lifting plate, so that filling pipes can insert into bread and conduct filling of four bread at one time simultaneously. The multi-station simultaneous quantitative filling device increases work efficiency and at the same time also reduces labor intensity of workers.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

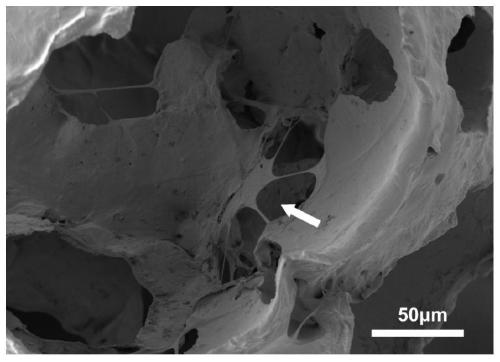

Preparation method of coal gangue foam concrete

InactiveCN104478467AAdvantages of preparation methodReduce pollutionCeramicwareFoam concreteFoaming agent

The invention discloses a preparation method of coal gangue foam concrete. The preparation method comprises the steps of firstly, weighing 1 part by weight of a foaming agent KD-1 and 10-30 parts by weight of water, uniformly mixing, and then, foaming in a high-speed dispersion machine ( with the rotating speed being 2000-3000rad / min) for 3-5 minutes to prepare foam for later use; then, weighing 20 parts by weight of PO425 cement, 55-65 parts by weight of coal gangue with the particle size of 0.5-6mm, 15-20 parts by weight of water and an additional early strength agent accounting for 3-5% of the cement in weight, and then, uniformly stirring in a stirrer to prepare concrete slurry; next, adding the preparative foam into the concrete slurry, and stirring for 2-6 minutes until the slurry is uniform to obtain foam concrete slurry; and finally, injecting the prepared foam concrete slurry into a mould prepared in advance for molding, standing for 24 hours, then, placing the molded foam concrete slurry into a standard constant-temperature and constant-humidity concrete curing box (at the temperature being 19-21 DEG C, relative humidity being 95-99%) to cure until all stages of concrete are obtained. According to the preparation method, the coal gangue foam concrete is prepared by taking the uncalcined large-particle coal gangue as a raw material, so that the aim of changing waste materials into valuable things is achieved, the production cost is reduced, and the production efficiency is improved.

Owner:HUNAN UNIV OF SCI & TECH

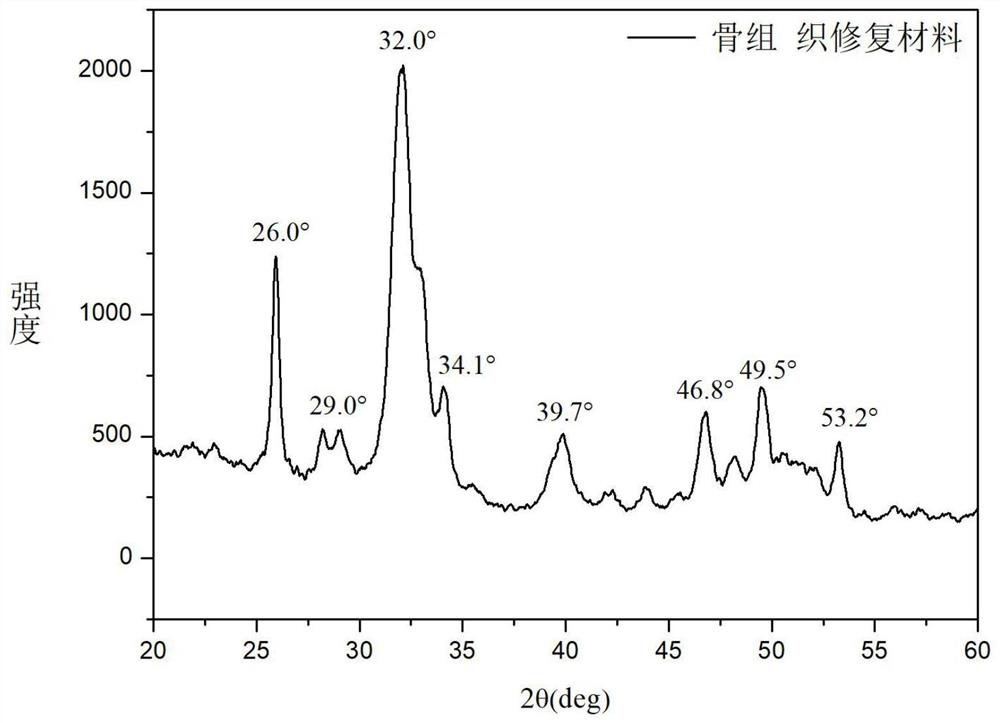

Bone tissue repair material as well as preparation method and application thereof

ActiveCN112158817ALower requirementMeet filling needsTissue regenerationPhosphorus compoundsO-Phosphoric AcidTissue repair

The invention discloses a bone tissue repair material and a preparation method and application thereof. The preparation method comprises the steps that in a liquid phase system with the pH value of 10-12, soluble calcium salt and soluble phosphate or phosphoric acid with the molar ratio of Ca to P being 5: 3 are subjected to an in-situ co-precipitation reaction on a natural polymer A, and hydroxyapatite natural polymer A nano-composite particles are formed after precipitate is dried and ground; and hydroxyapatite natural polymer A nano-composite particles are mixed uniformly with a natural polymer B solution, a mixture is put into a mold, vacuum freeze drying is carried out, soaking is carried out with absolute ethyl alcohol, and drying is carried out to obtain the bone tissue repair material. The bone tissue repair material is loose and porous, hydroxyapatite is not prone to leaking from the bone tissue repair material, and the bone tissue repair material is good in water absorption,soft after absorbing water and good in elasticity and can be used for common bone defect repair in the oral implant department, the oral repair department, the orthopedics department and other surgerydepartments. The preparation method is simple and convenient to operate, easy to automate, clean in reagent and low in cost.

Owner:HUBEI SAILUO BIOLOGICAL MATERIAL CO LTD

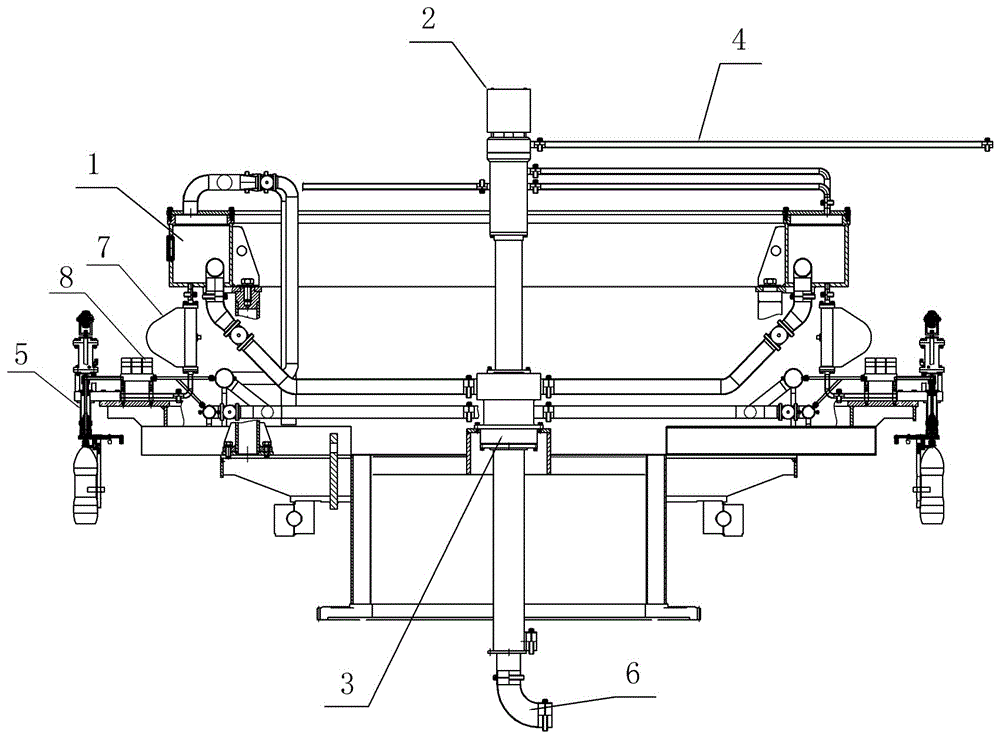

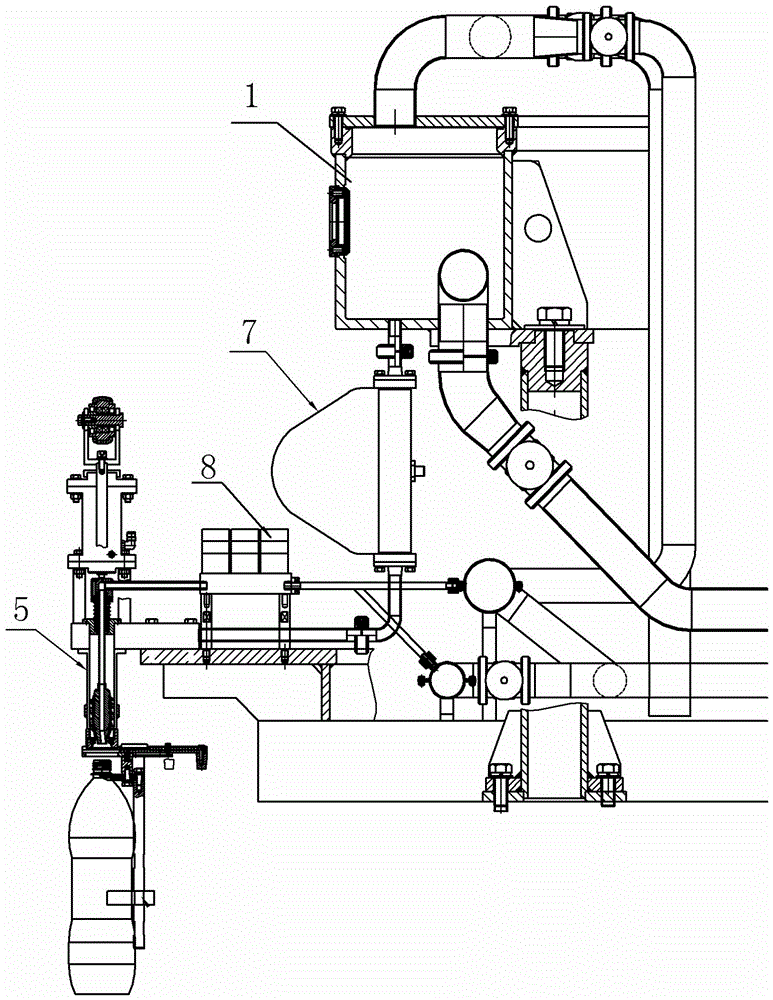

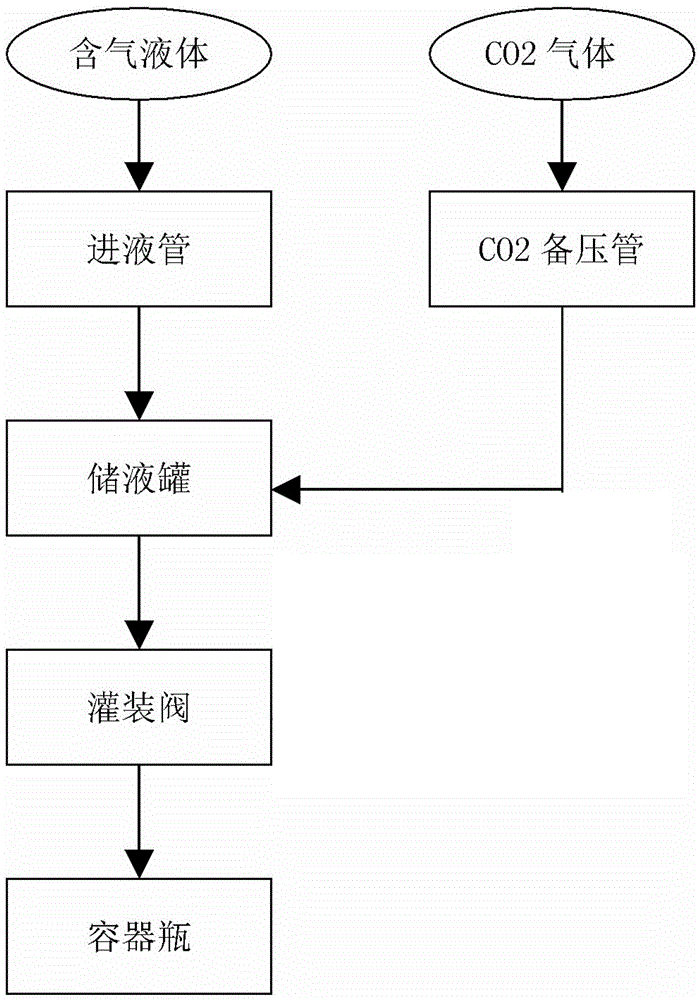

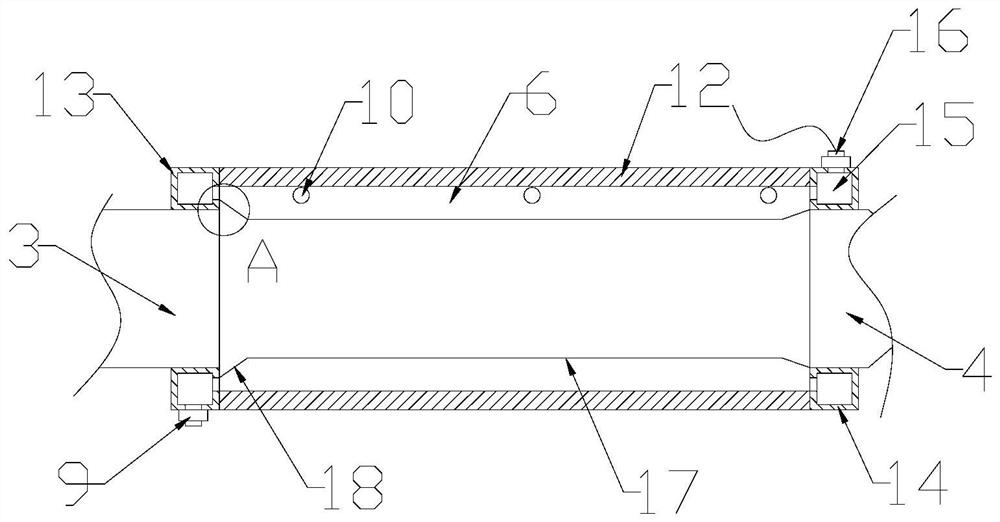

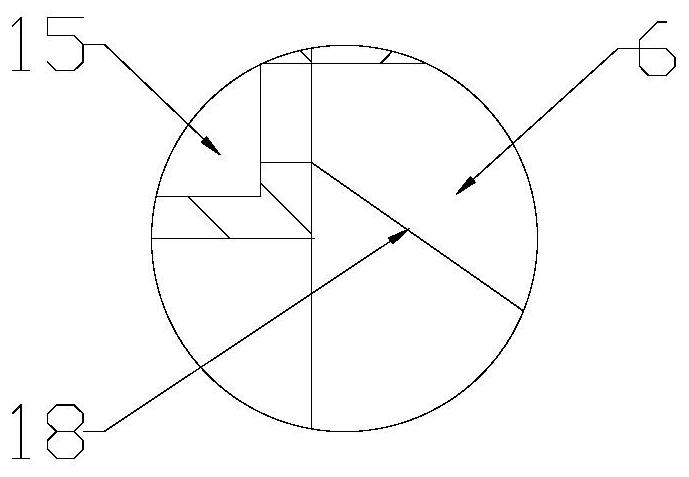

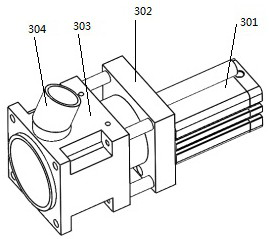

Multifunctional filling machine and filling method thereof

PendingCN106629550AMeet filling needsReduce equipment costsFilling using counterpressureFilling without pressureEngineeringDistributor

The invention relates to a multifunctional filling machine and a filling method thereof. A liquid storing tank, an upper distributor, a lower distributor, a filling valve and a CO2 pressure preparation pipe are arranged on the filling machine, and a multifunctional control pipeline for transporting different liquid is mounted on the filling machine; the different liquid enters the liquid storing tank through a liquid inlet pipe and the lower distributor, and then filling in different methods is performed according to the characteristics of the liquid; and after filling of a certain product is completed and before the filling of another product is performed, the filling machine is cleaned by adopting CIP cleaning, and then the product is shifted, and the filling work of another product is continued. According to the filling machine and the filling method thereof disclosed by the invention, the filling requirement of different liquid can be met, the filling machine is quick and convenient in work, the application scope of the filling machine can be improved, and the equipment requirement of the filling machine is effectively reduced, so that the equipment cost and the production cost are reduced.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

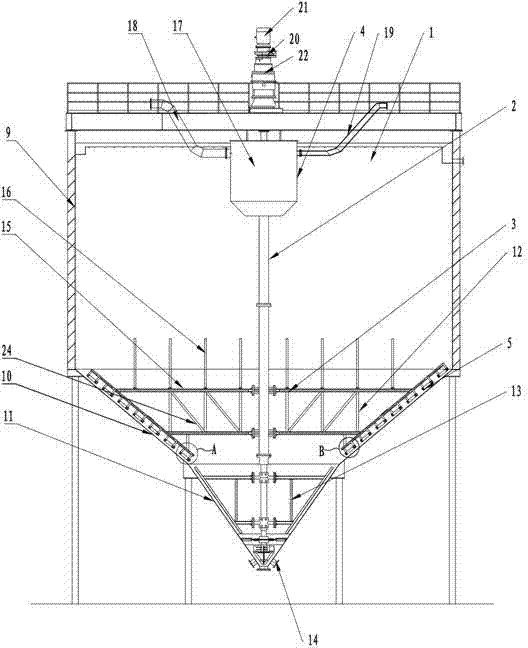

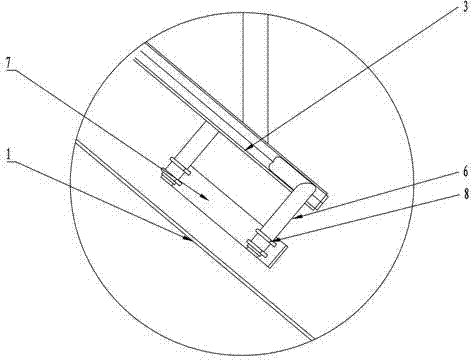

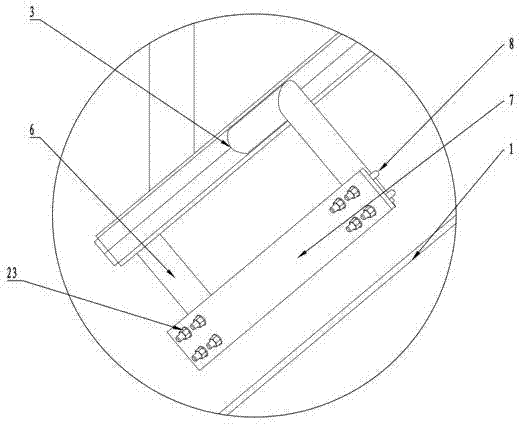

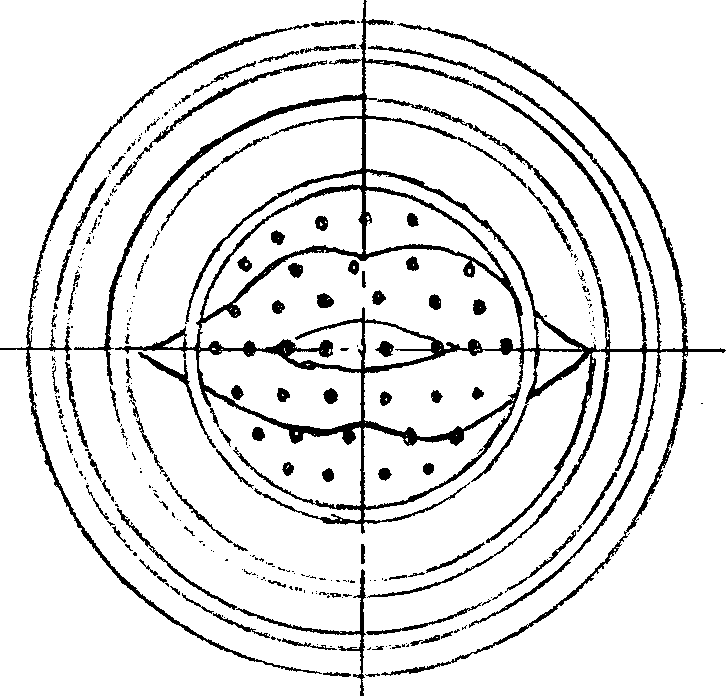

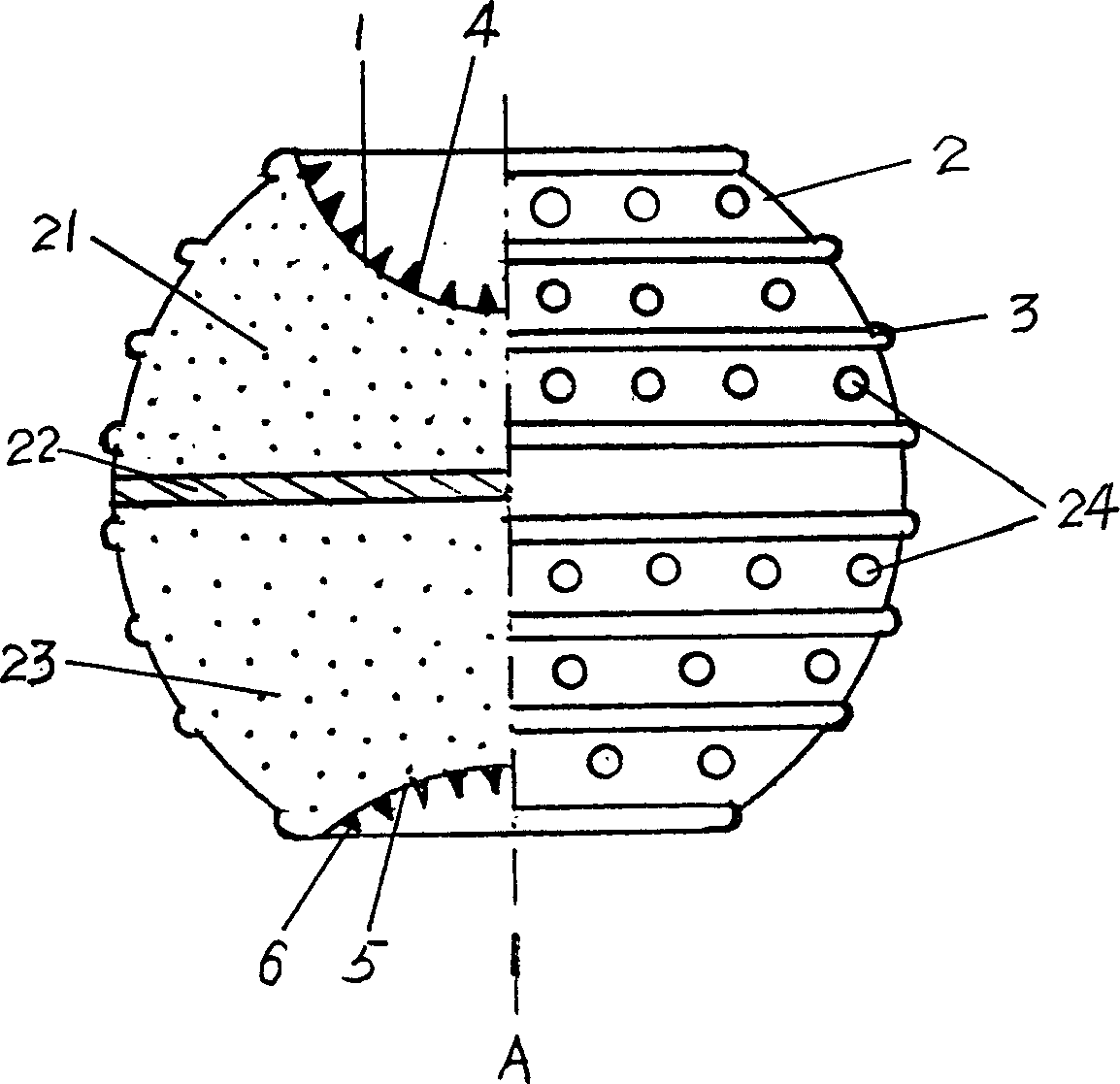

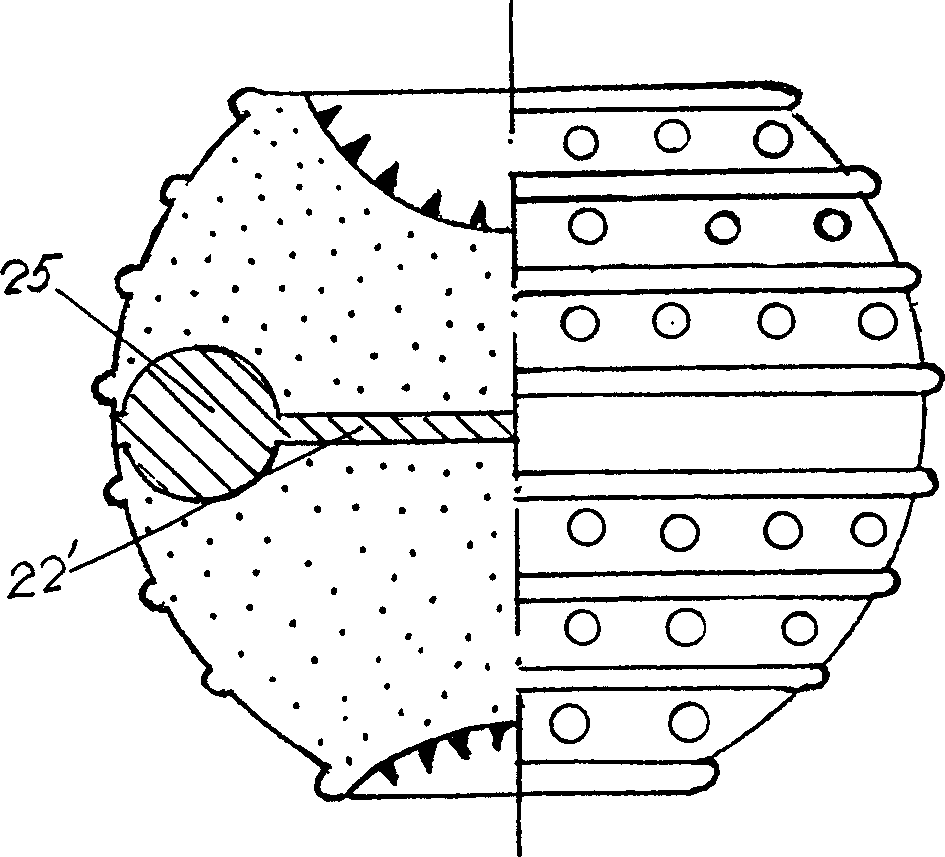

Paste concentrating machine

ActiveCN104707369AAchieve pulpingHigh torqueSettling tanks feed/dischargeSedimentation settling tanksHigh concentrationPulp and paper industry

The invention relates to a paste concentrating machine. The paste concentrating machine comprises a pool body, a feeding device, a main shaft, a harrow frame, harrow teeth and a driving device for driving the main shaft to rotate, wherein the feeding device is mounted at the upper part of the pool body, and the pool body comprises a cylindrical section, a middle cone section and a base cone section; the harrow teeth are connected with the main shaft through the harrow frame, and each harrow tooth comprises steel tubes fixed on the harrow frame, a rectangular steel plate and U-shaped bolts; each rectangular steel plate is fixed on the corresponding steel tube through the corresponding U-shaped bolt, and each rectangular steel plate can move up and down along the corresponding steel tube. The paste concentrating machine disclosed by the invention is large in torque of a transmission system, and can work in high-concentration ore pulp; the harrow teeth can move up and down, so that the distance between the harrow teeth and the pool wall is more accurate and is suitable for different pool bodies in a certain range. By using the paste concentrating machine disclosed by the invention, the underflow concentration of 65% or above can be realized, and paste pulping is realized, so that a filling requirement is met.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

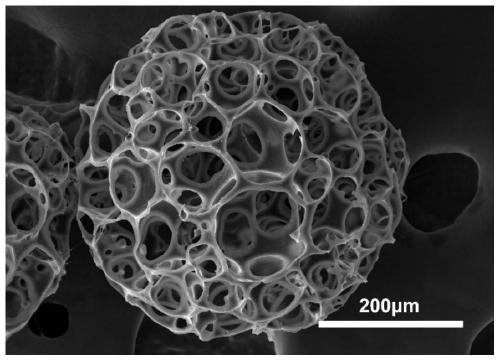

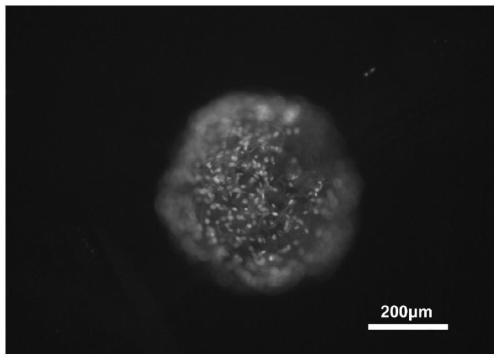

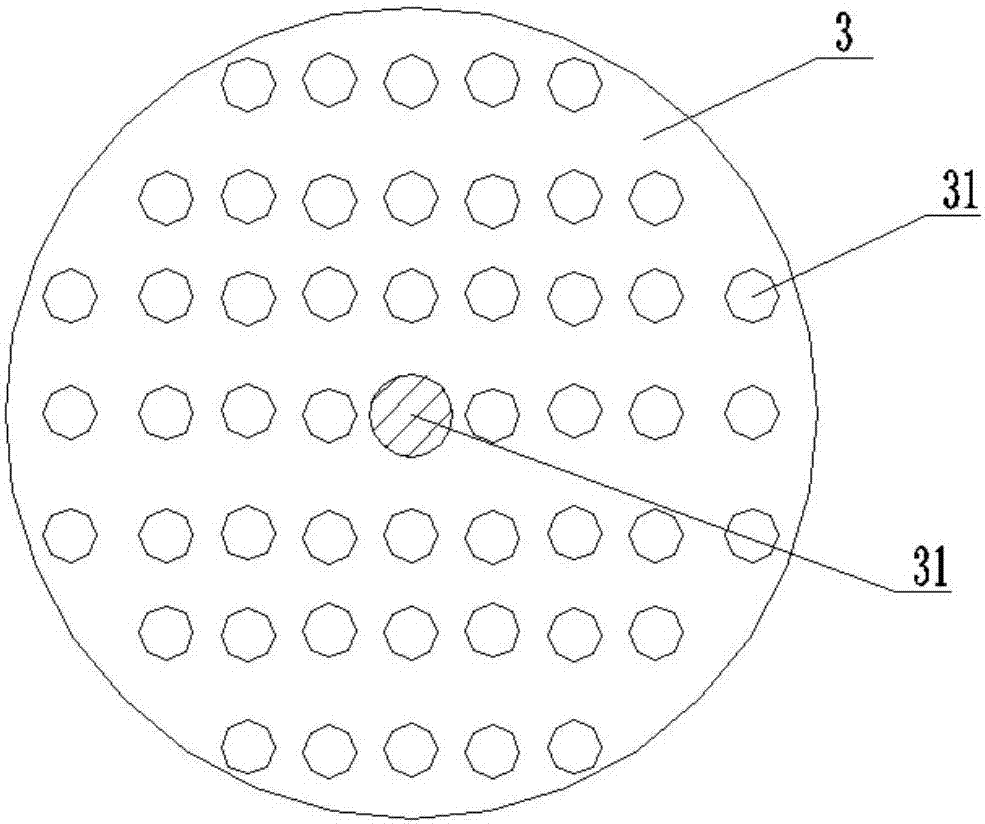

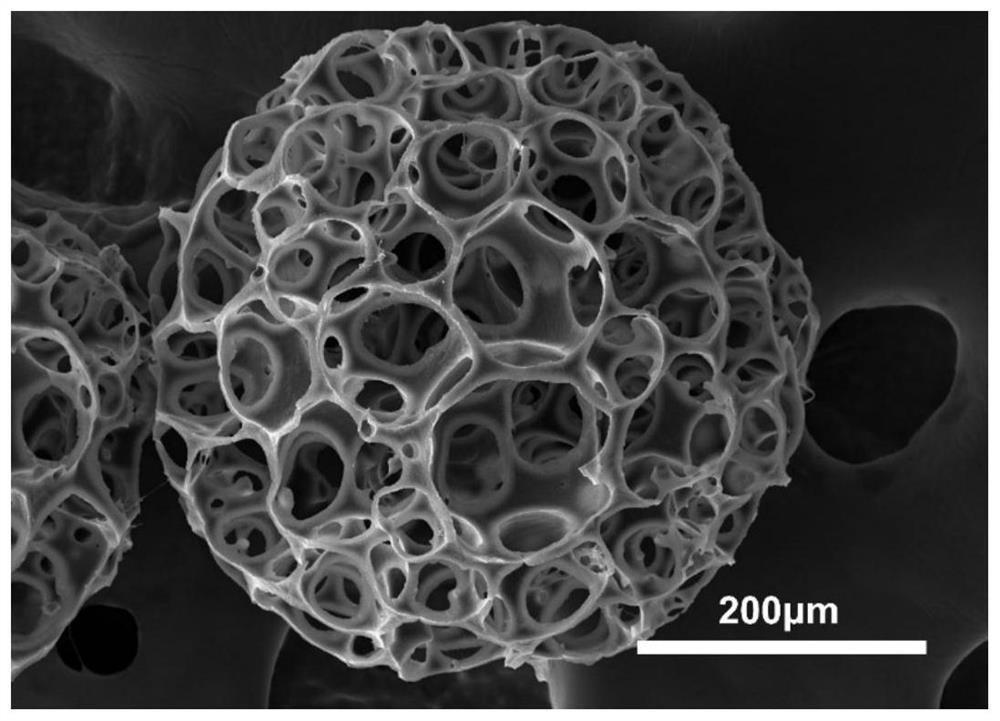

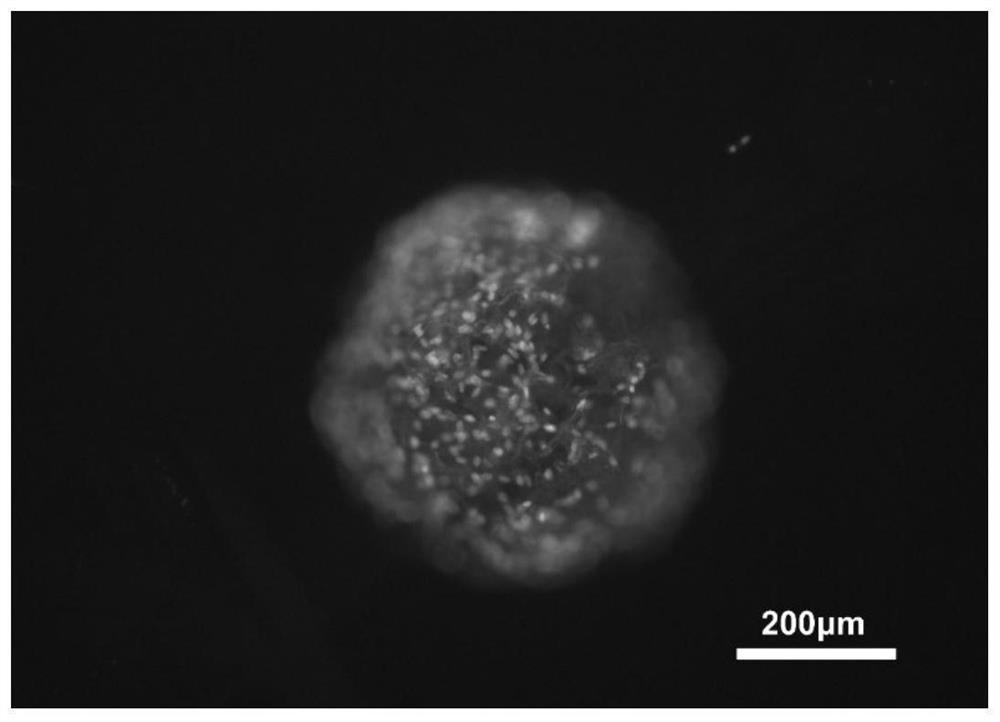

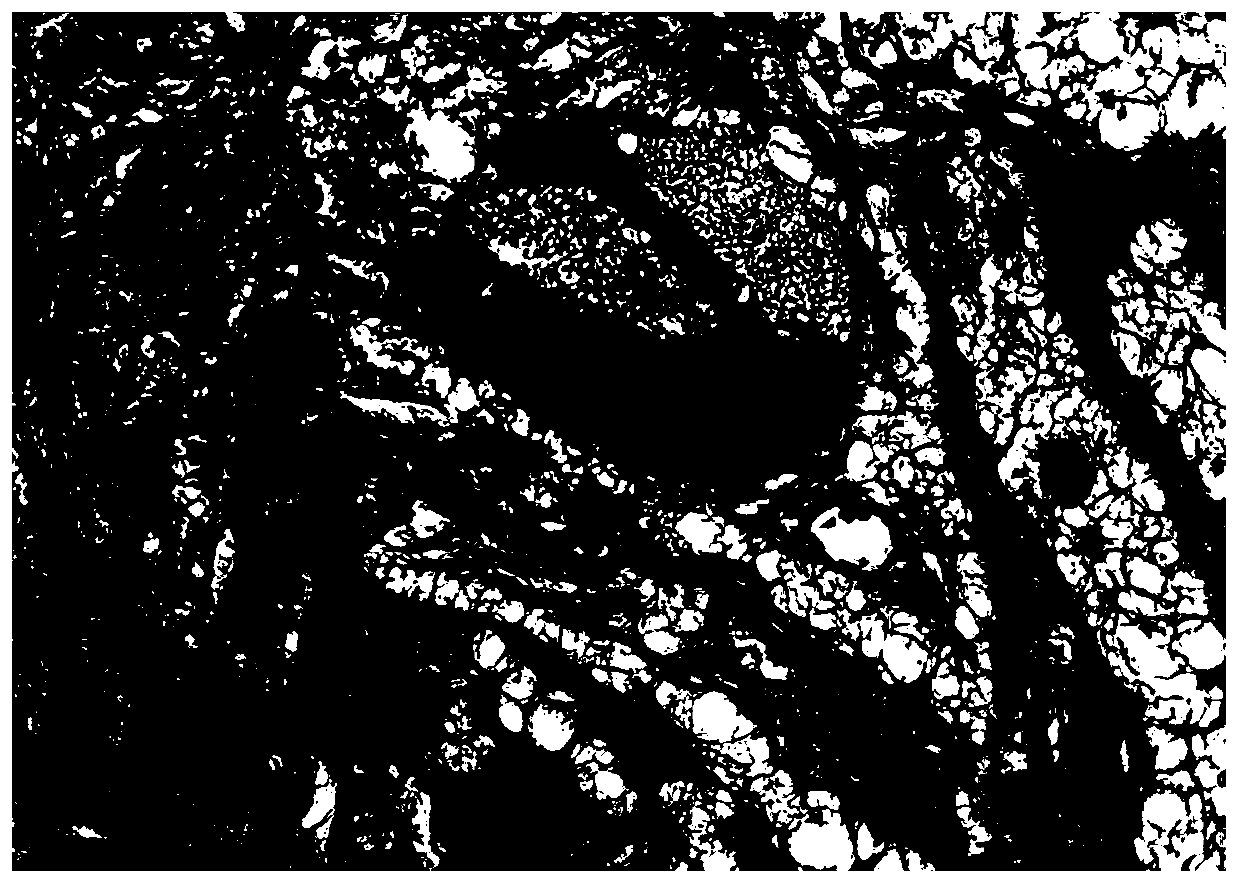

High-porosity polycaprolactone porous microsphere scaffold used for bone tissue regeneration and preparation method for high-porosity polycaprolactone porous microsphere scaffold

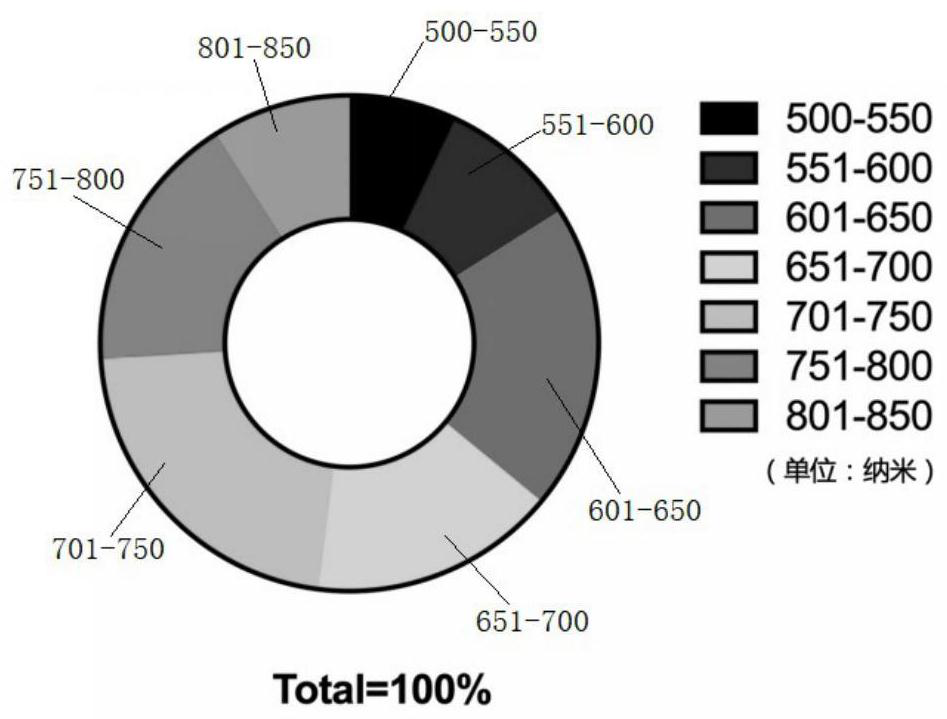

ActiveCN111249524AHigh porosityLarge aperture sizePharmaceutical delivery mechanismTissue regenerationFoaming agentBone tissue

The invention discloses a high-porosity polycaprolactone porous microsphere scaffold used for bone tissue regeneration and a preparation method for the high-porosity polycaprolactone porous microsphere scaffold. By taking gelatin as a pore-foaming agent and by taking a multiple emulsion-solvent evaporation method as the basis, polycaprolactone porous microspheres are prepared; pores in surfaces and pores in the high-porosity polycaprolactone porous microspheres communicate with each other; the porosity of the microspheres is 75.28%-90.73%; and the pore size of each pore is 43-217 [mu]m. The polycaprolactone porous microsphere scaffold has high porosity, so that the scaffold can provide more space for growth of bone tissue; meanwhile, space occupied by a polycaprolactone material is also reduced, and the shortcoming of slow degradation of polycaprolactone is remedied; and the porous microspheres have a larger pore size, and are suitable for ingrowth of cells and regeneration of the bonetissue.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

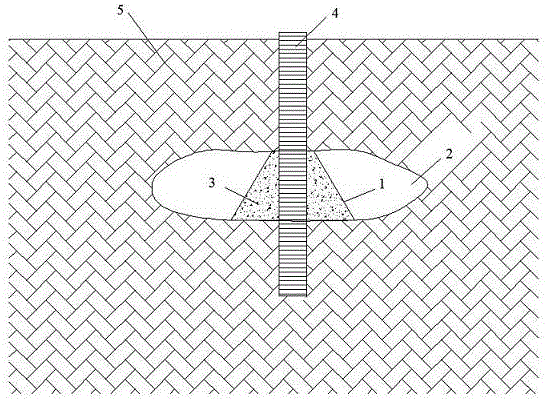

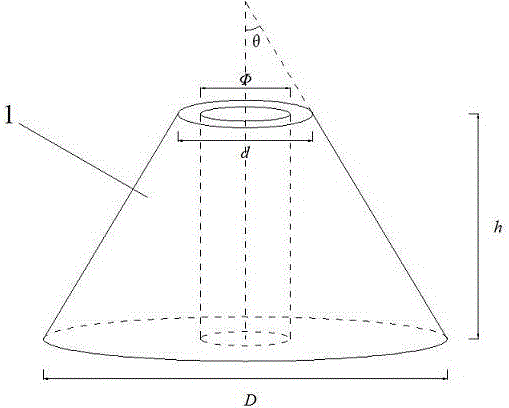

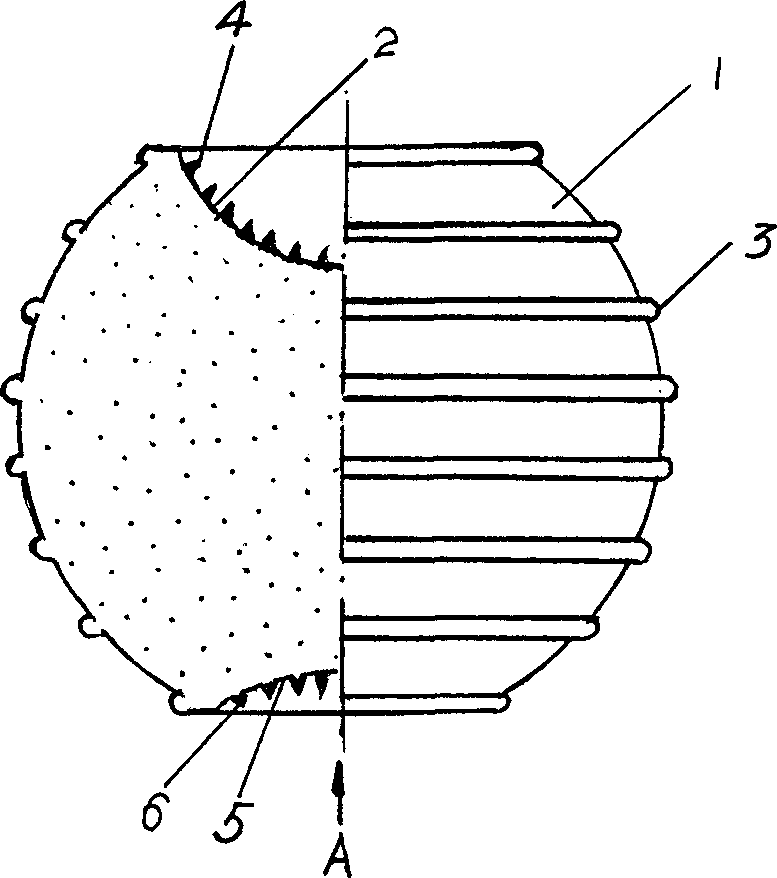

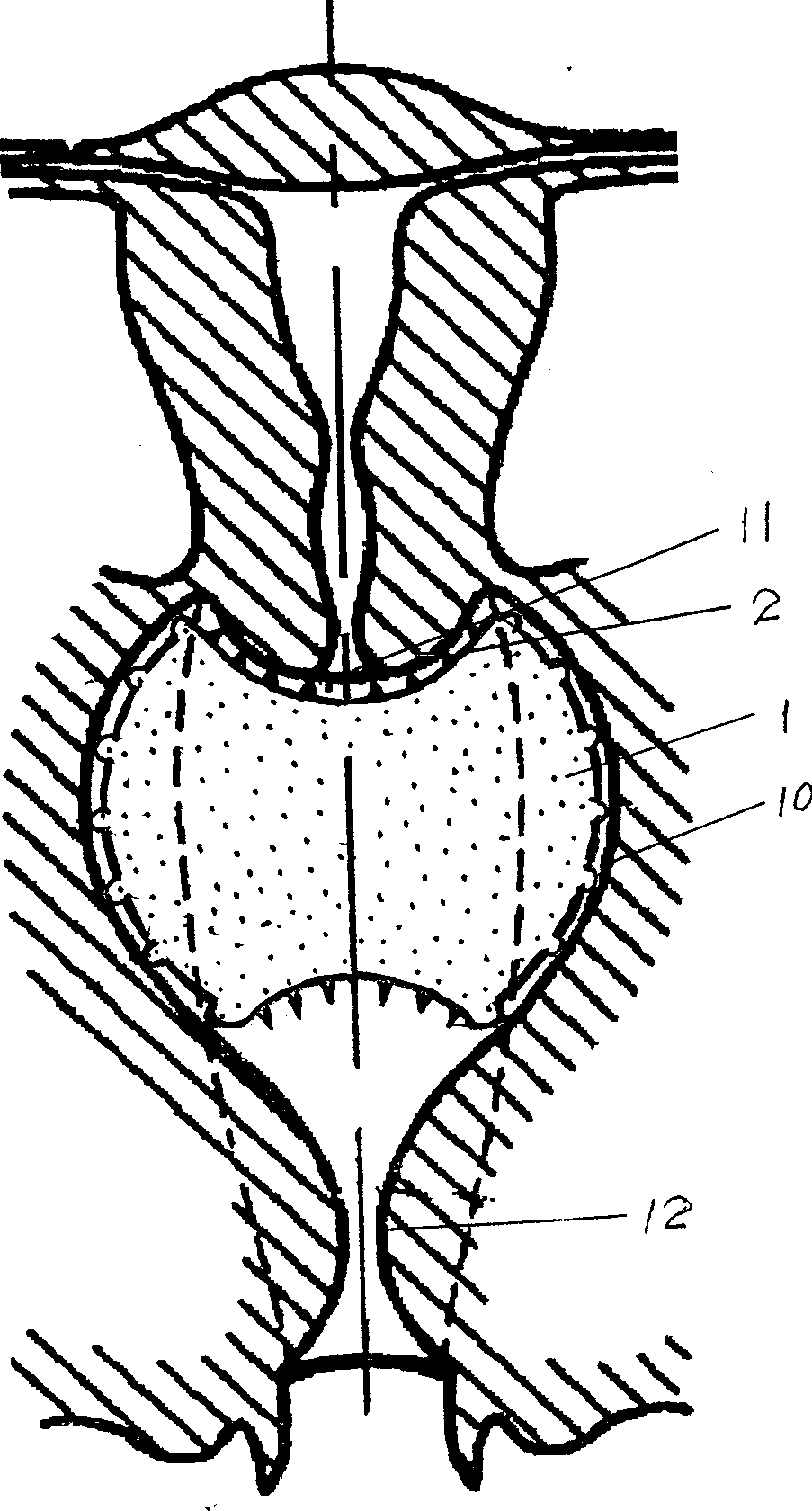

Capsule type pouring and filling method and structure for large-size karst pile foundation construction

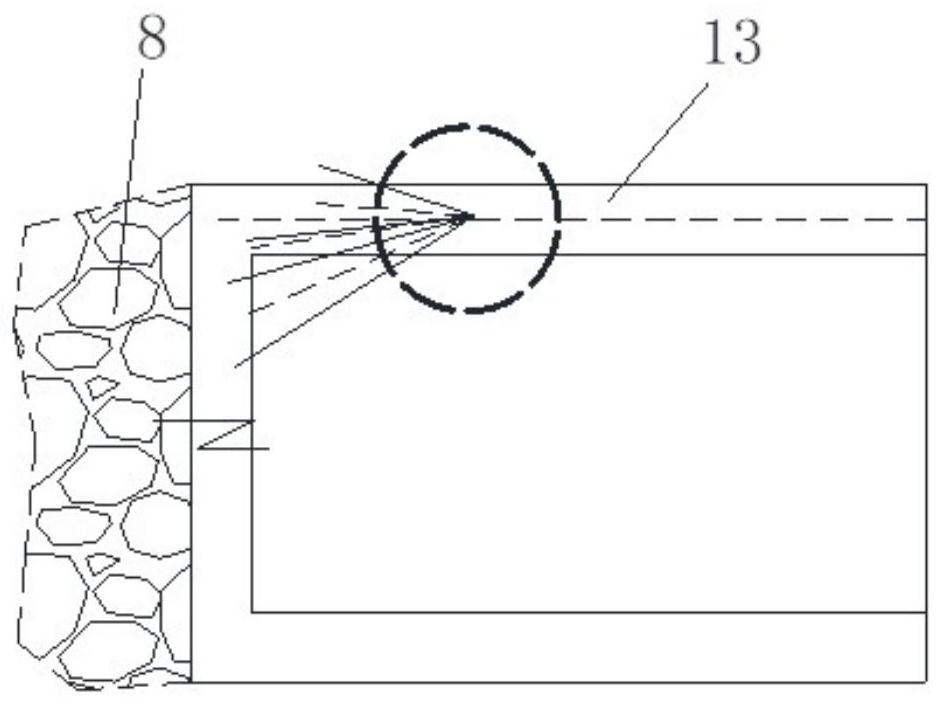

ActiveCN105926658AGuaranteed contactGood force carrierFoundation engineeringStructure of the EarthMixed materials

The invention discloses a capsule type pouring and filling method and structure for large-size karst pile foundation construction. The method includes the steps that A, the karst distribution range and rough dimension are determined through advanced exploration; B, the dimension of a capsular bag is determined according to the diameter of a pile foundation and the karst height, wherein the capsular bag is in a circular truncated cone shape; C, the capsular bag is sewn; D, a small amount of filler is injected into the capsular bag, the capsular bag is slowly placed downwards from the ground into the karst area with a rope along a pile hole; E, light bubble mixed materials are pumped into the capsular bag until the capsular bag is full; and F, the light bubble mixed materials are solidified fast, and construction of the pile foundation is carried out. Structurally, the karst area is distributed in a stratum, the pile foundation penetrates through the karst area and is embedded in the stratum, the pile foundation penetrates through the capsular bag via a cylinder hole in the capsular bag, the capsular bag and the karst area are connected, the capsular bag is filled with the light bubble mixed materials and is in the circular truncated cone shape, and the capsular bag is as high as the karst area. The capsule type pouring and filling method and structure for large-size karst pile foundation construction are reasonable in technology, economical, environmentally friendly, remarkable in effect, and capable of meeting the filling requirement of large-size karst pile foundation construction in karst regions.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

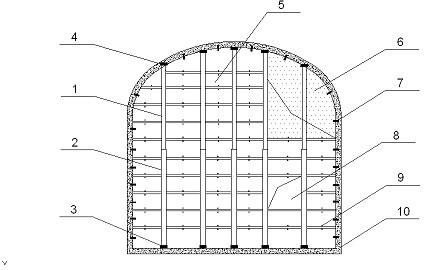

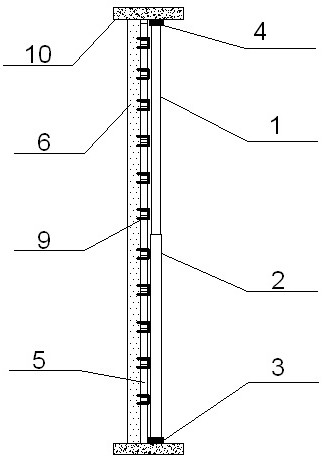

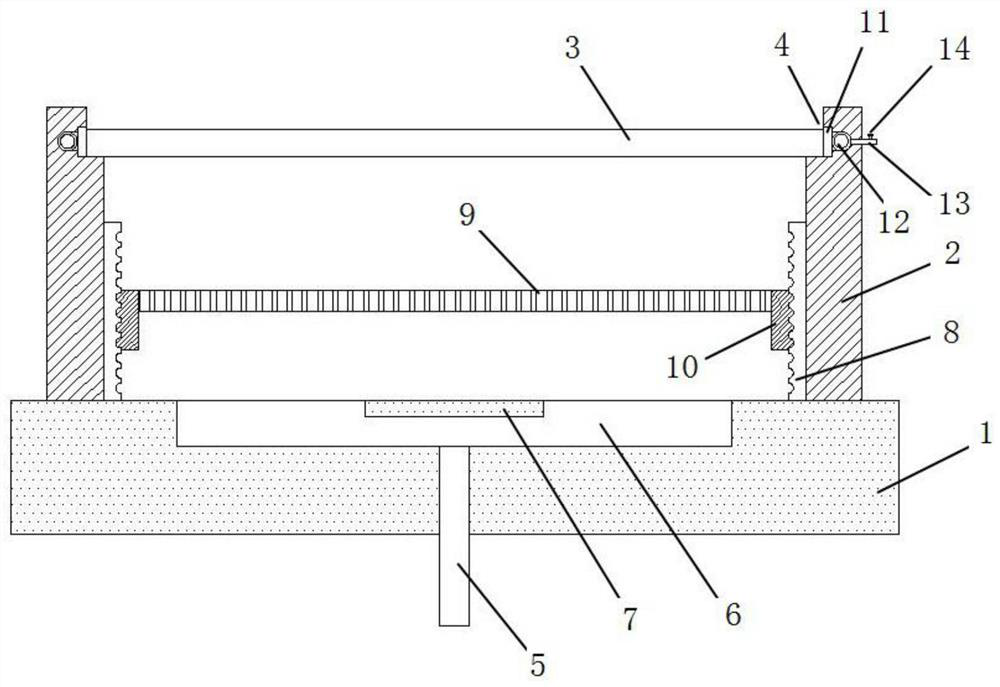

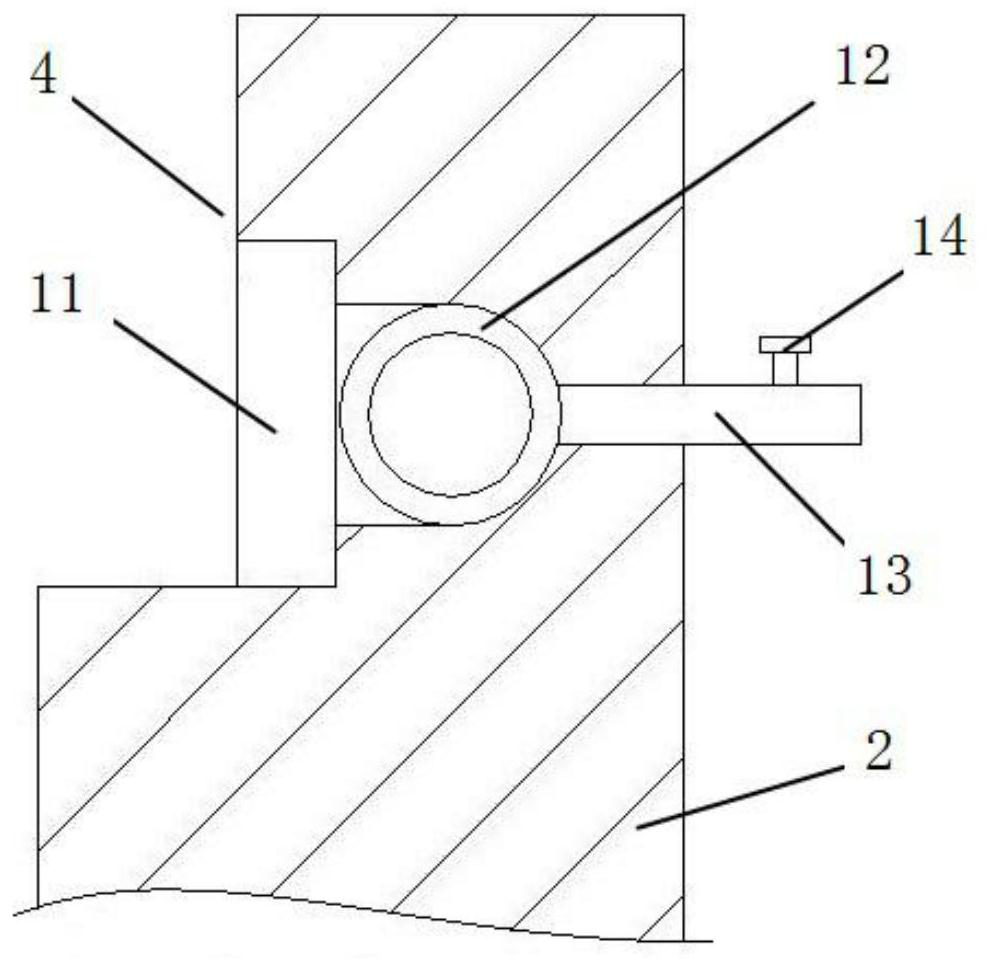

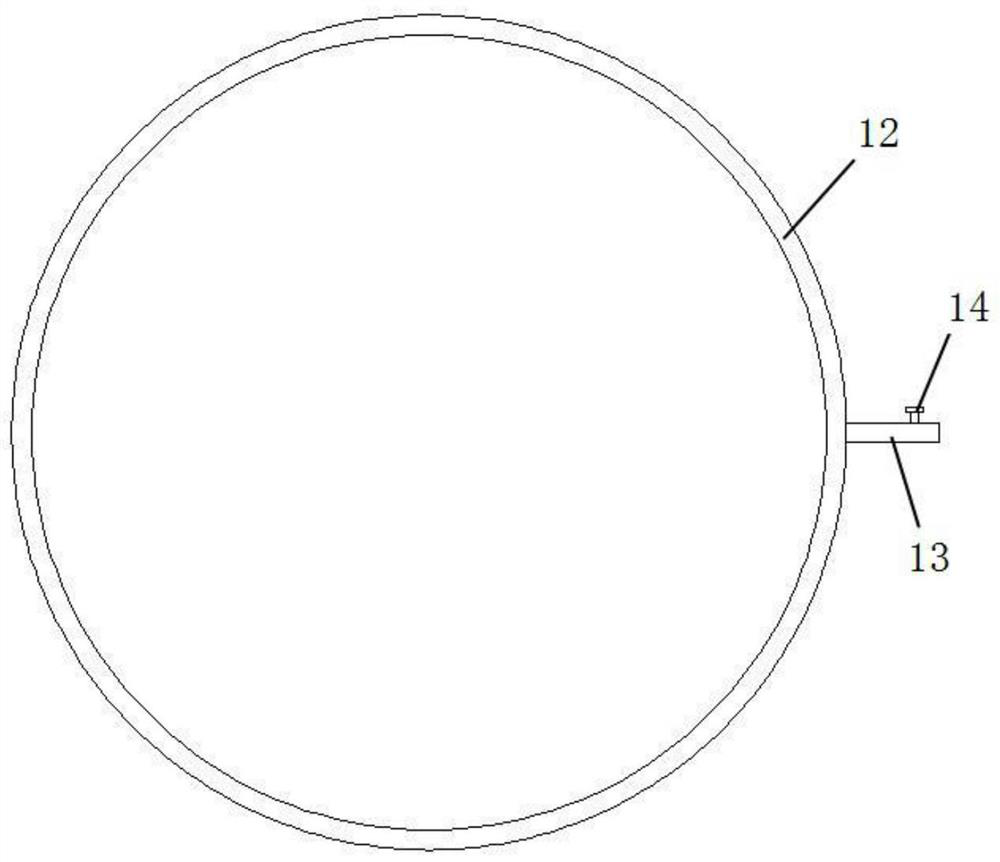

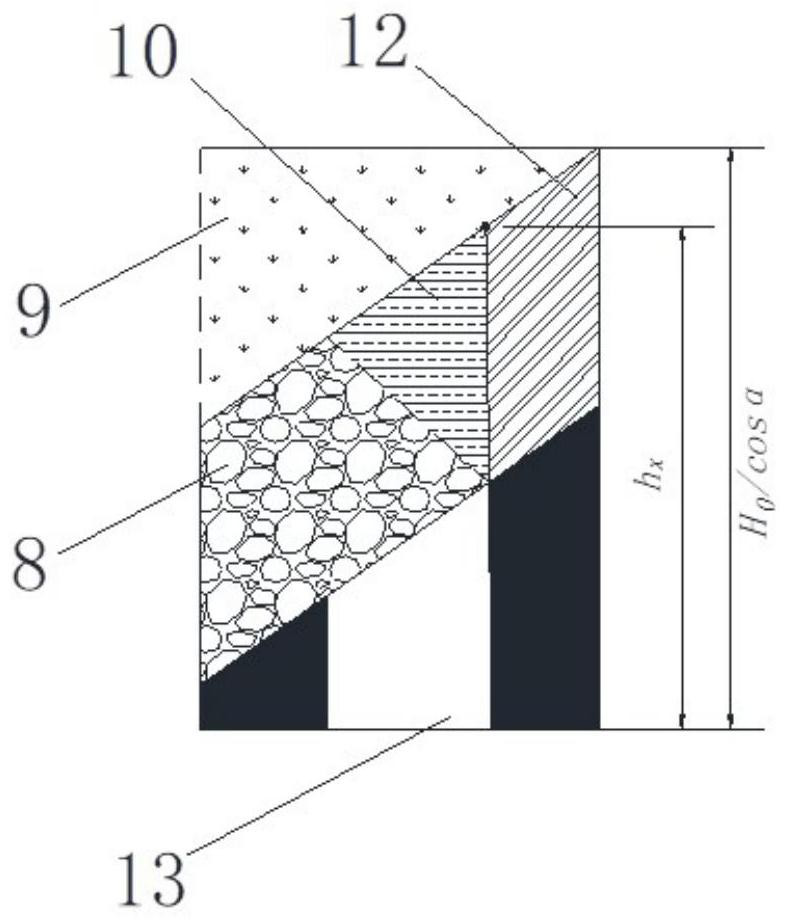

Detachable and usable roadway filling retaining wall and construction method thereof

PendingCN113356924ASimple structureEasy constructionMaterial fill-upArchitectural engineeringMechanical engineering

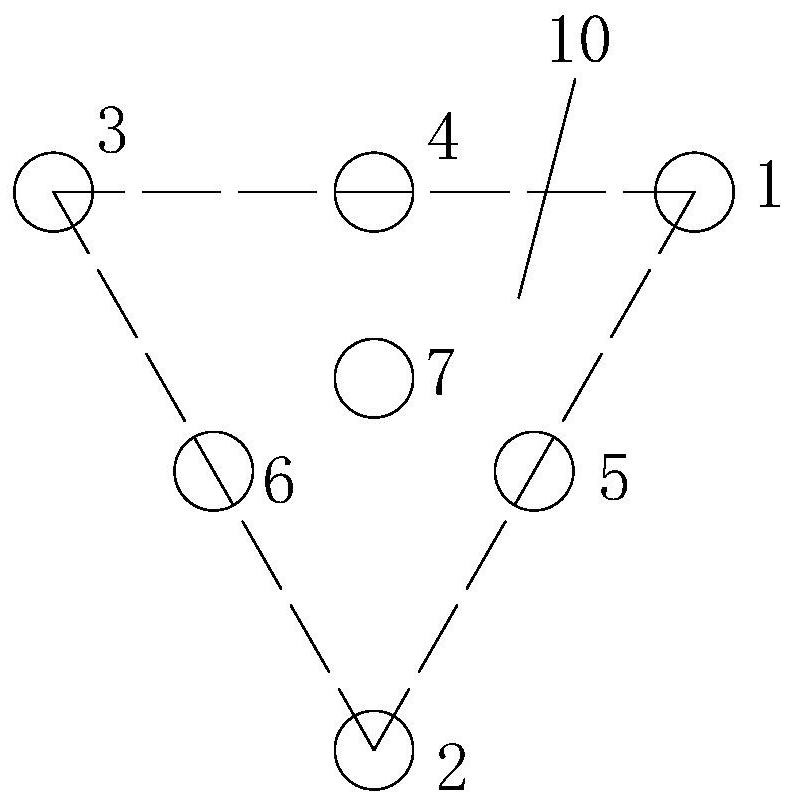

The invention relates to a detachable and usable filling retaining wall and a construction method thereof, and belongs to the technical field of underground mine filling and plugging. According to the technical scheme, the detachable and usable filling retaining wall comprises single hydraulic props, a bottom plate bearing plate (3), a top plate bearing plate (4), metal formworks (5) and filter cloth or geotechnical cloth (6), the single hydraulic props comprise upper props (1) and lower props (2) which are connected together, the single hydraulic props are arranged in a roadway at certain intervals, the upper ends of the upper props (1) and the lower ends of the lower props (2) in the single hydraulic props are fixed to the top plate bearing plate (4) and the bottom plate bearing plate (3) respectively, a metal formwork (5) is arranged between every two adjacent single hydraulic props, and the filter cloth or geotechnical cloth (6) is flatly laid on the metal formworks (5). The detachable and usable filling retaining wall has the beneficial effects of being simple in structure, rapid and convenient to construct, safe, reliable, few in material, capable of being disassembled and reused, small in engineering amount and investment and capable of meeting the underground filling requirement.

Owner:HEBEI IRON & STEEL GRP MINING

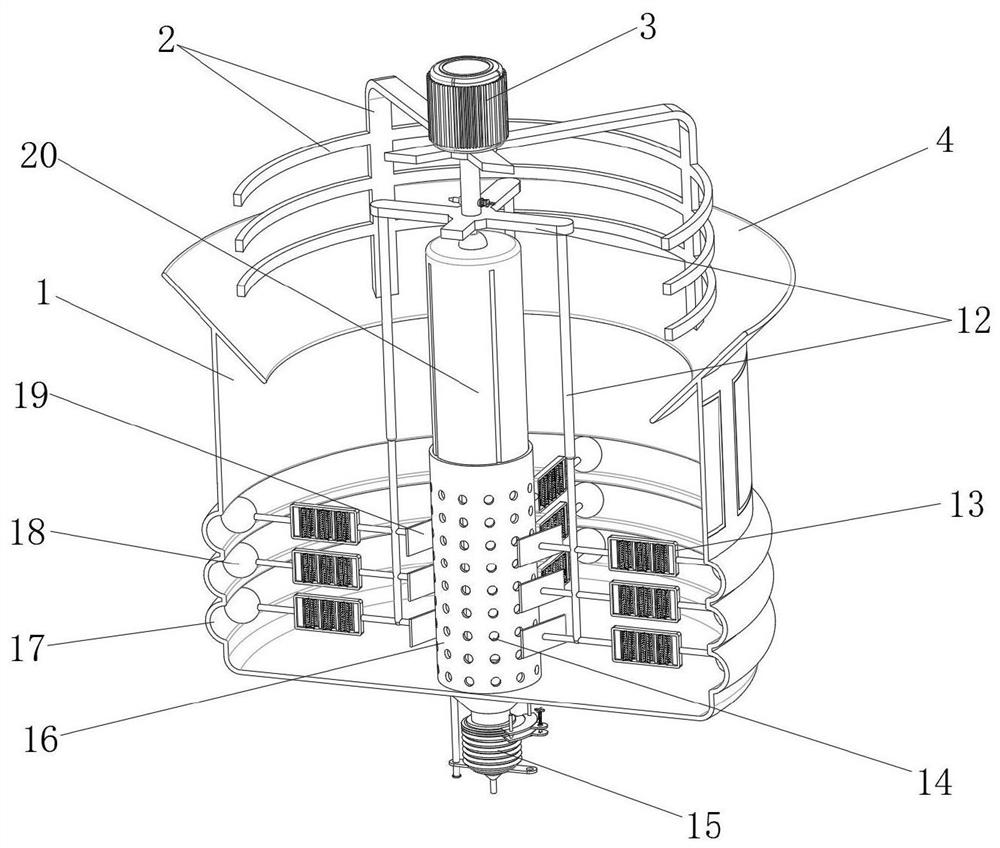

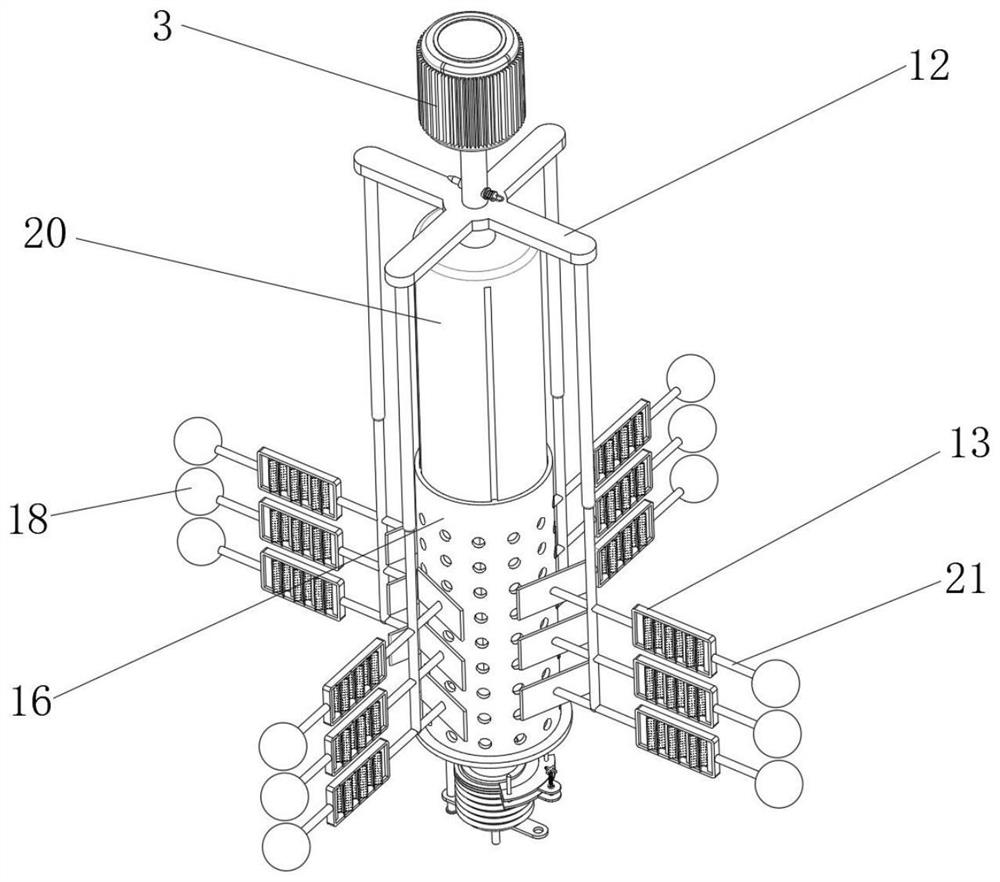

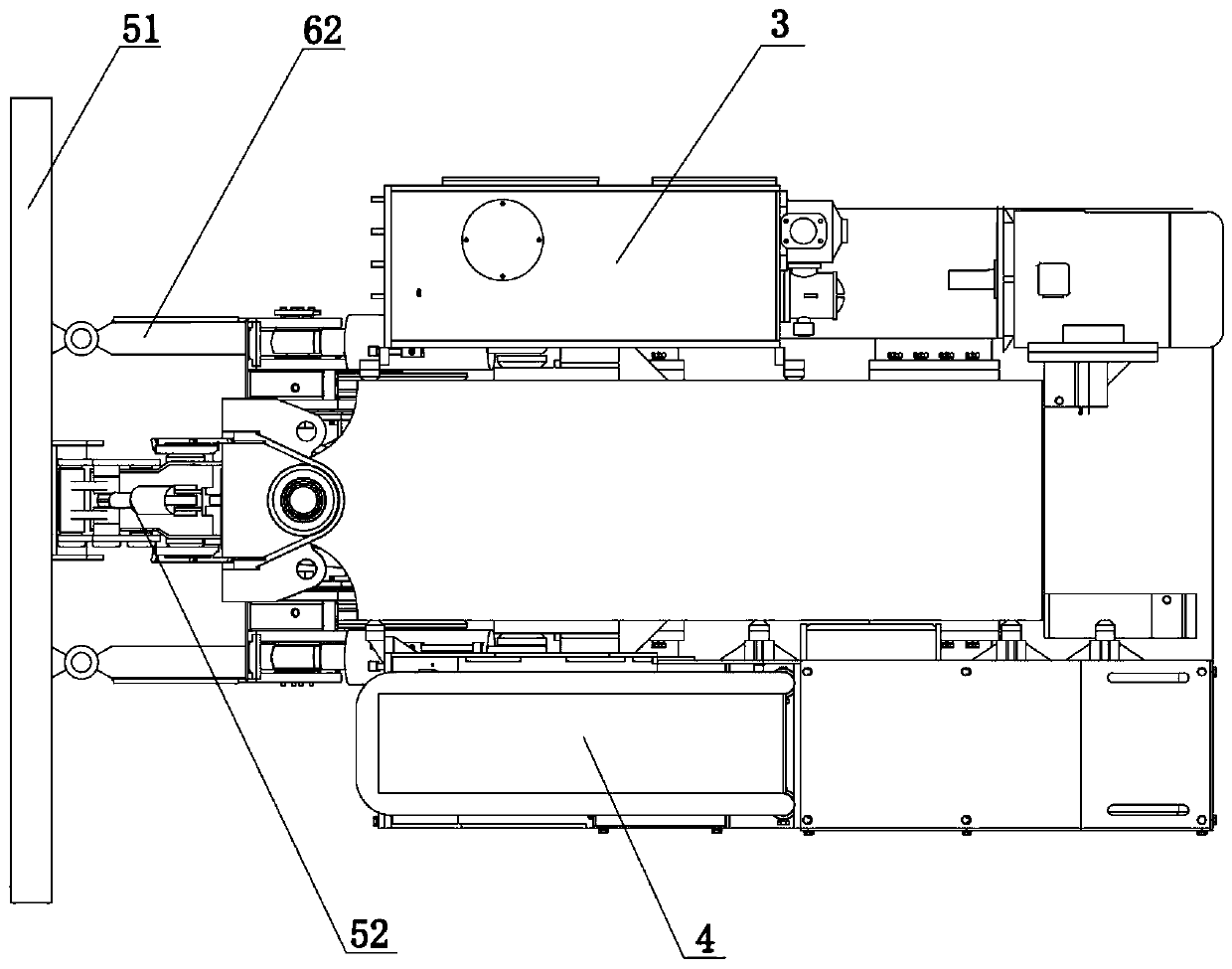

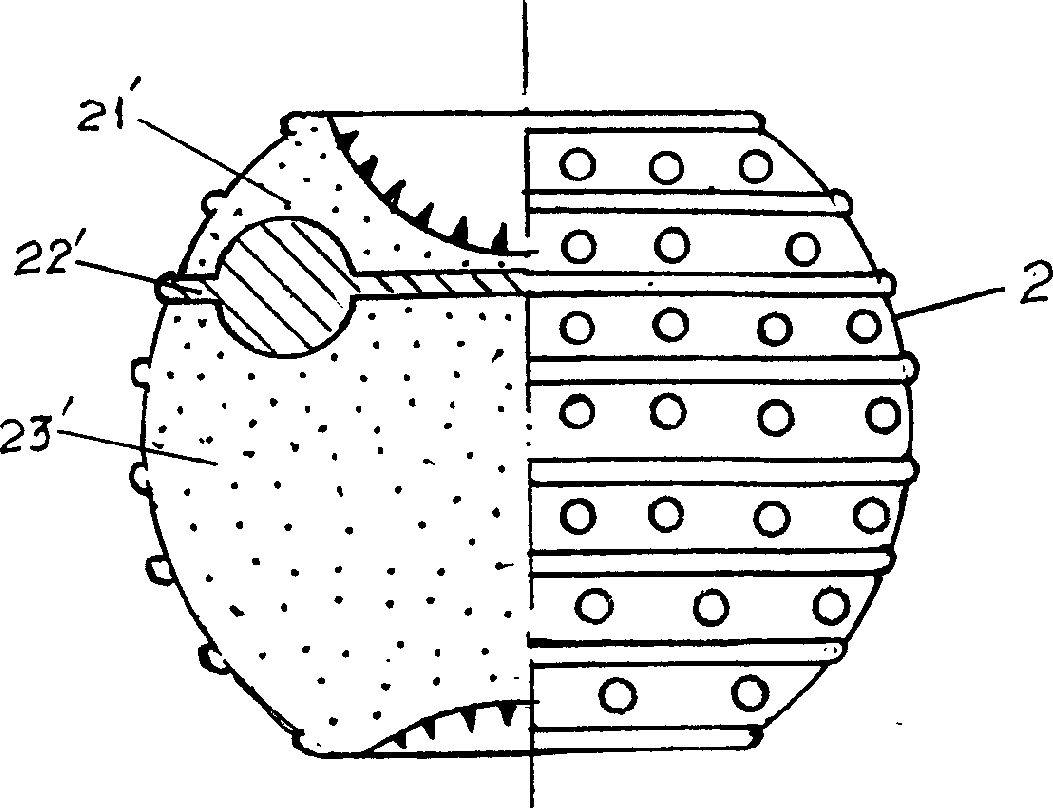

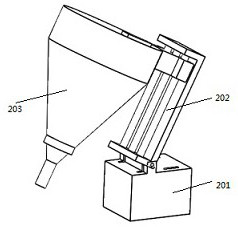

A coating machine facilitating seed loading

InactiveCN107347303AMeet filling needsAvoid stickingPackagingSeed coating/dressingEngineeringCoating

The invention relates to the technical field of seed processing equipment, in particular to a coating machine which is convenient for seed filling. The device of the present invention includes a feeding part, a mixing part, and a filling part. The mixing part is arranged below the feeding part. The mixing part includes a mixing box and a seed outlet. The lower part of the mixing box is inclined, and the filling part Including finished product box, seed entry door, multiple measuring cups, seed exit, measuring cup fixing plate, the entrance of the finished product box is connected with the seed outlet, the bottom of the finished product box is provided with a seed entry door, and multiple measuring cups are set under the seed entry door, and multiple measuring cups pass through the measuring cup fixing plate Fastened together, the outlet of the measuring cup sets the seeds out the door. The device of the present invention integrates medicine mixing, mixing, drying and seed filling, and can accurately fill multiple packaging bags at the same time, meeting the filling demand when the seasonal demand for seed coating is especially strong. The device of the invention has the characteristics of simple structure, high reliability, simple operation and the like.

Owner:湖北腾龙种业有限公司

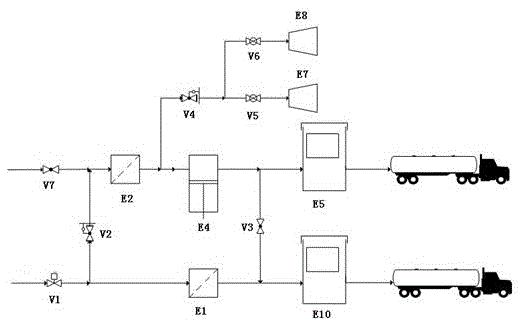

Comprehensive recycling system for high-pressure and low-pressure associated gas of gas field

ActiveCN105627087AReduce energy consumptionLess investmentInternal combustion piston enginesGaseous fuelsGas generatorGenerating unit

The invention discloses a comprehensive recycling system for high-pressure and low-pressure associated gas of a gas field. The system comprises a high-pressure dehydration unit, a low-pressure dehydration unit, a CNG compressor, a CNG compression gas filler, two gas generator sets and a high-pressure dehydration unit gas filler; the CNG compressor is connected between the low-pressure dehydration unit and the CNG compression gas filler; the high-pressure dehydration unit is connected with the high-pressure dehydration unit gas filler; an inlet of the high-pressure dehydration unit is connected with an emergent block valve; a pressure adjusting valve is connected between an inlet of the low-pressure dehydration unit and an inlet of the high-pressure dehydration unit; and the two gas generator sets are respectively connected between the low-pressure dehydration unit and the CNG compressor through pressure relief valves. The system not only can satisfy the filling demands in trial extracting period, but also can satisfy the filling demands in normal extraction period, and satisfies the filling demands under the condition of gas source pressure attenuation in normal extraction; and two filling system can be singly used or combined for use, so that the energy consumption is reduced, and the investment is saved.

Owner:庆城中旖新能源有限公司 +1

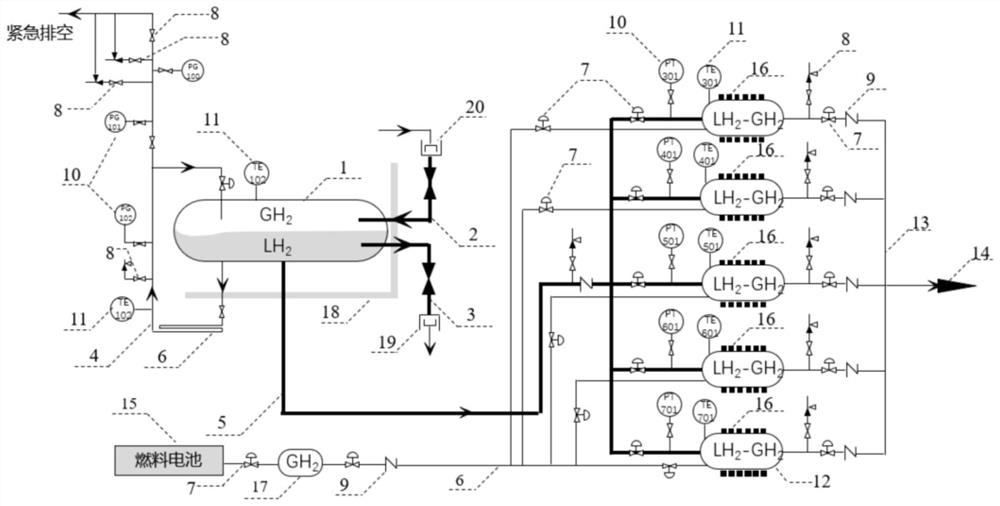

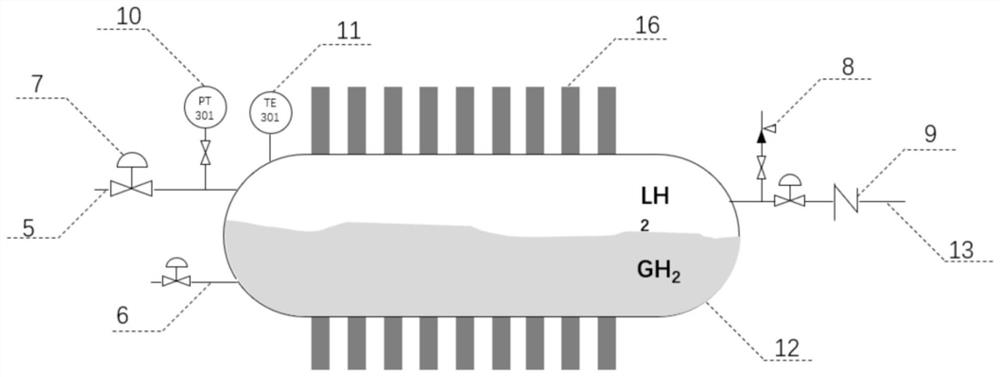

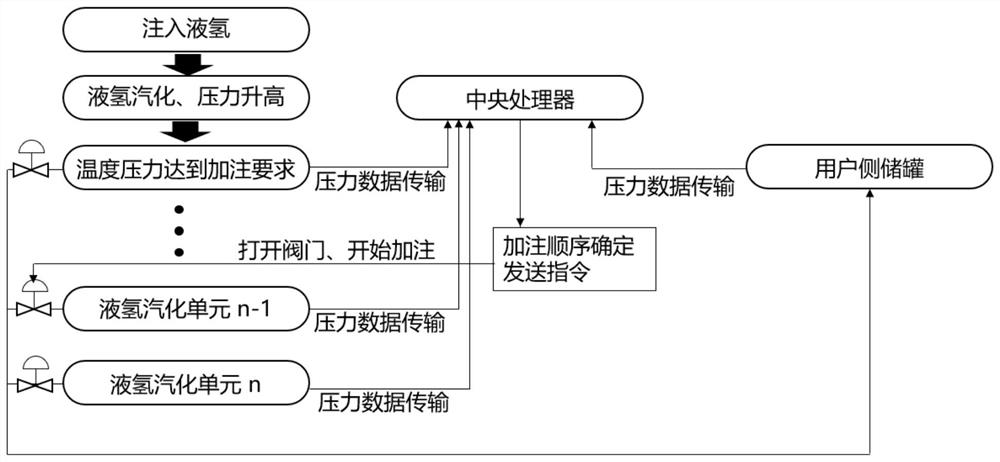

Efficient movable gas-liquid dual-mode hydrogen fuel filling device

PendingCN114087540AImprove utilization efficiencyReduce hazardous emissionsPipeline systemsFluid handledLiquid hydrogenTruck

The invention relates to an efficient movable gas-liquid dual-mode hydrogen fuel filling device. The efficient movable gas-liquid dual-mode hydrogen fuel filling device is operated according to the steps that liquid hydrogen is supplemented by the gas-liquid dual-mode hydrogen fuel filling device; the gas-liquid dual-mode hydrogen fuel filling device prepares for filling; and a liquid hydrogen vaporization unit enters an enhanced heat exchange stage, the liquid hydrogen vaporization unit fully exchanges heat with air through metal fins on a liquid hydrogen vaporization cavity, liquid hydrogen in the liquid hydrogen vaporization cavity absorbs heat to be vaporized, the pressure is increased, and after the set filling pressure is reached, filling preparation is completed. The device has the beneficial effects that extra electric energy can be generated and stored in a vehicle-mounted battery; the device can be used for driving truck platforms and in other application occasions, the energy self-sufficiency rate is greatly increased, the economical efficiency of hydrogenation facilities is improved, and the service market and the application range of the hydrogenation facilities are expanded; and low-temperature liquid hydrogen is used as a main hydrogen storage mode, so that the hydrogen storage capacity is improved, a gaseous hydrogen fuel filling mode and a liquid hydrogen fuel filling mode can be provided, and the application scenarios of the filling system are increased.

Owner:ZHEJIANG ZHENENG TECHN RES INST

High-porosity polycaprolactone porous microsphere scaffold for bone tissue regeneration and preparation method thereof

ActiveCN111249524BHigh porosityLarge aperture sizePharmaceutical delivery mechanismTissue regenerationFoaming agentMedicine

The invention discloses a high-porosity polycaprolactone porous microsphere scaffold used for bone tissue regeneration and a preparation method for the high-porosity polycaprolactone porous microsphere scaffold. By taking gelatin as a pore-foaming agent and by taking a multiple emulsion-solvent evaporation method as the basis, polycaprolactone porous microspheres are prepared; pores in surfaces and pores in the high-porosity polycaprolactone porous microspheres communicate with each other; the porosity of the microspheres is 75.28%-90.73%; and the pore size of each pore is 43-217 [mu]m. The polycaprolactone porous microsphere scaffold has high porosity, so that the scaffold can provide more space for growth of bone tissue; meanwhile, space occupied by a polycaprolactone material is also reduced, and the shortcoming of slow degradation of polycaprolactone is remedied; and the porous microspheres have a larger pore size, and are suitable for ingrowth of cells and regeneration of the bonetissue.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

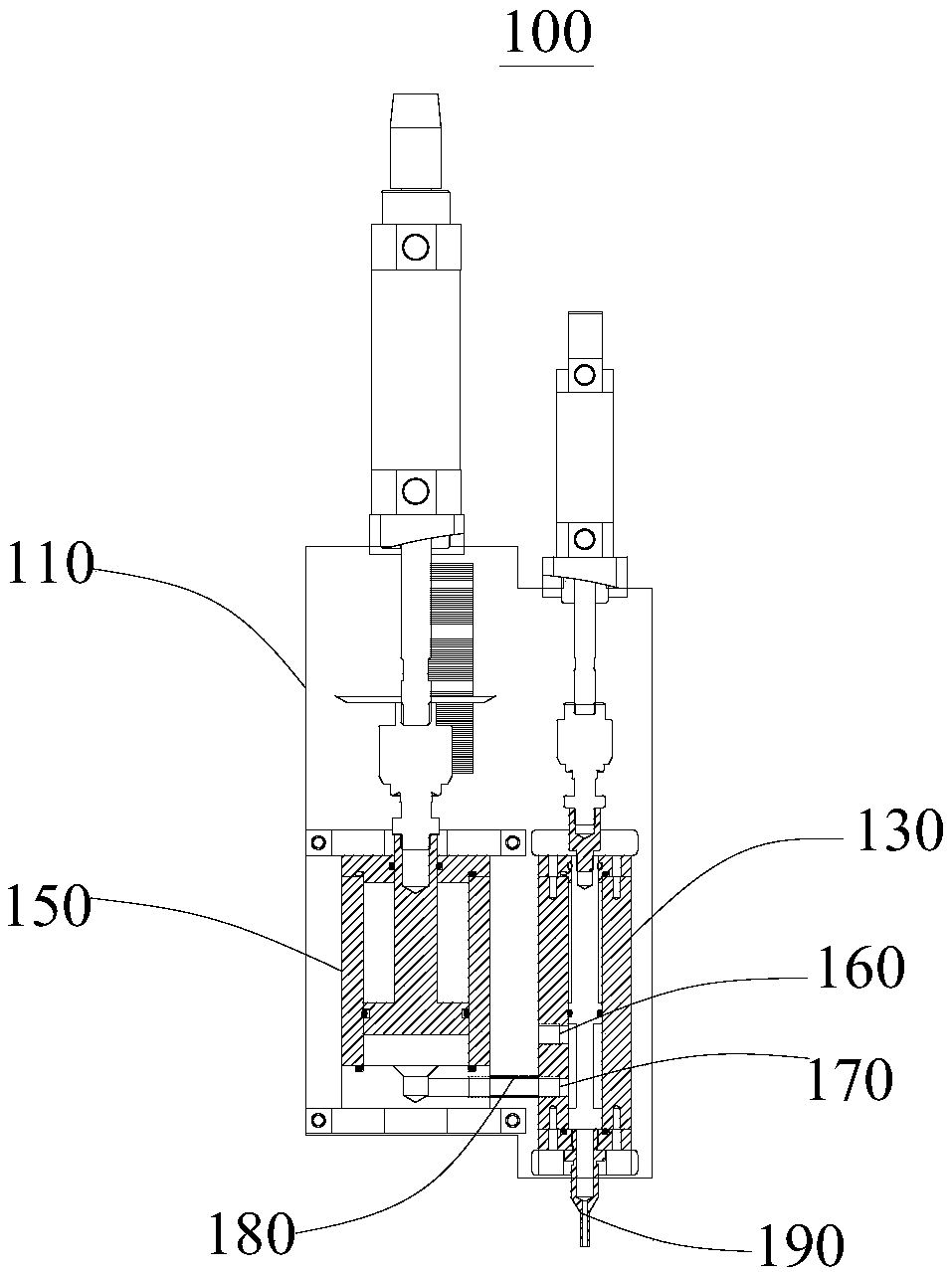

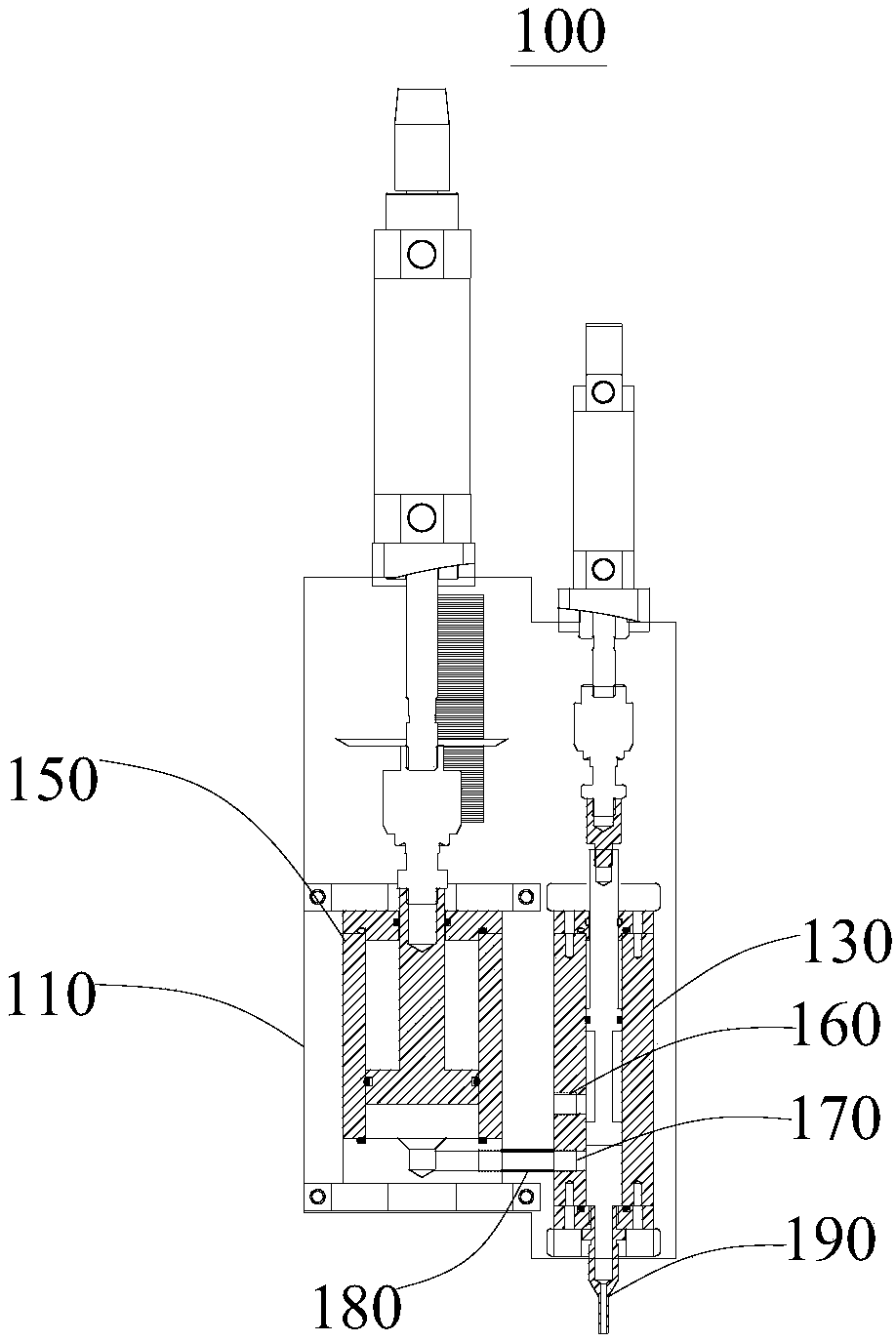

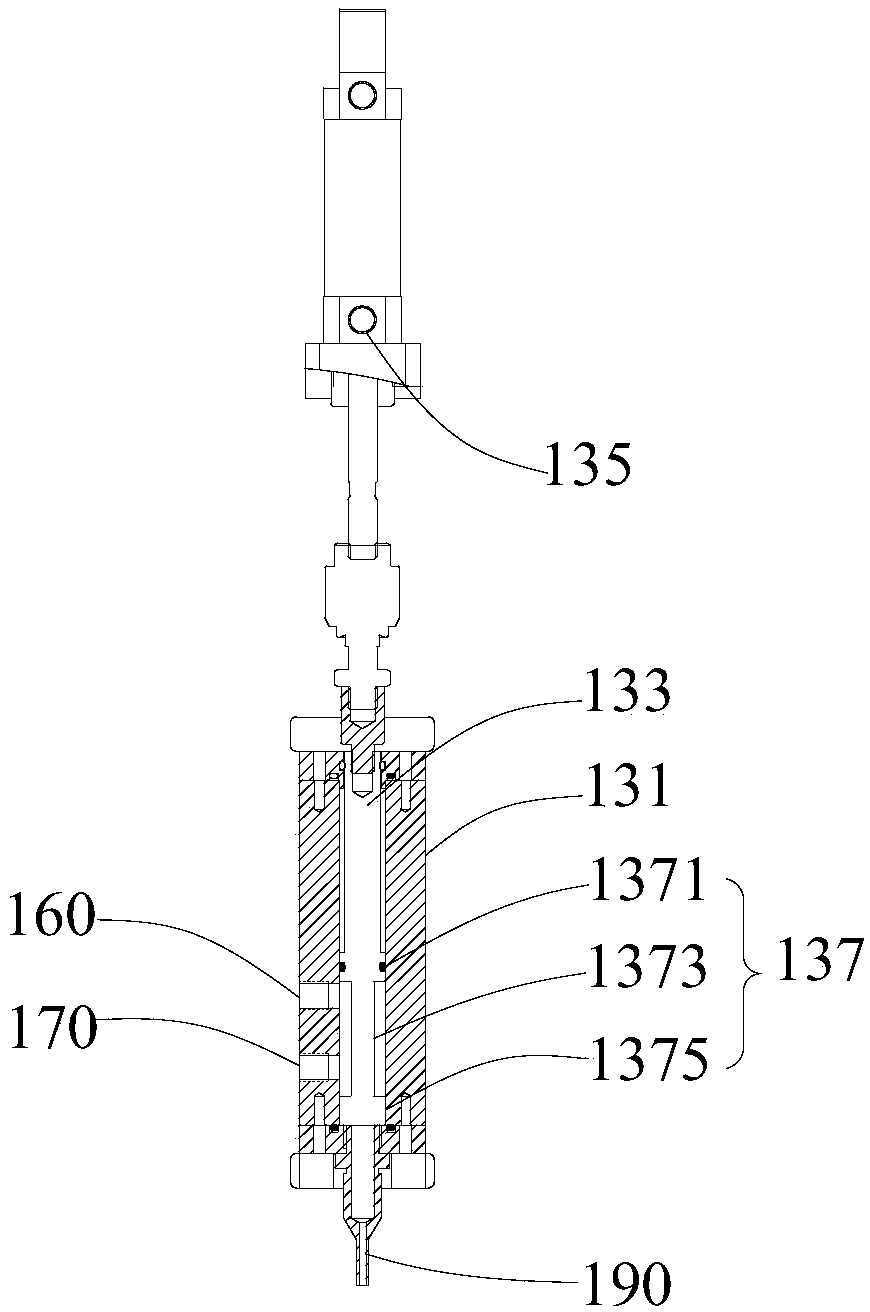

Liquid filling device and liquid filling system

The invention provides a liquid filling device and a liquid filling system, and relates to the technical field of workpiece liquid filling. The liquid filling device comprises a cylinder body fixing base plate, a first liquid filling cylinder and a second liquid filling cylinder, wherein the first liquid filling cylinder and the second liquid filling cylinder are arranged on the cylinder body fixing base plate, the first liquid filling cylinder is provided with a first connector and a second connector, the first connector is used for being connected with a liquid pressure barrel, the second connector is provided with an outer connecting pipe, the first connector selectively communicates with the second connector, the two ends of the outer connecting pipe are connected with the first liquidfilling cylinder and the second liquid filling cylinder respectively, one end of the first liquid filling cylinder is provided with a liquid filling nozzle, and the liquid filling nozzle selectivelycommunicates with the second interface. According to the liquid filling device, the second liquid filling cylinder is used for extracting, storing and filling liquid, so that the liquid to be poured in the liquid pressure barrel can be quickly extracted and filled into the liquid pressure barrel, the filling efficiency is high, and meanwhile the filling requirements of the high-liquid-volume high-viscosity filling liquid can be met.

Owner:XIAMEN INTRETECH +1

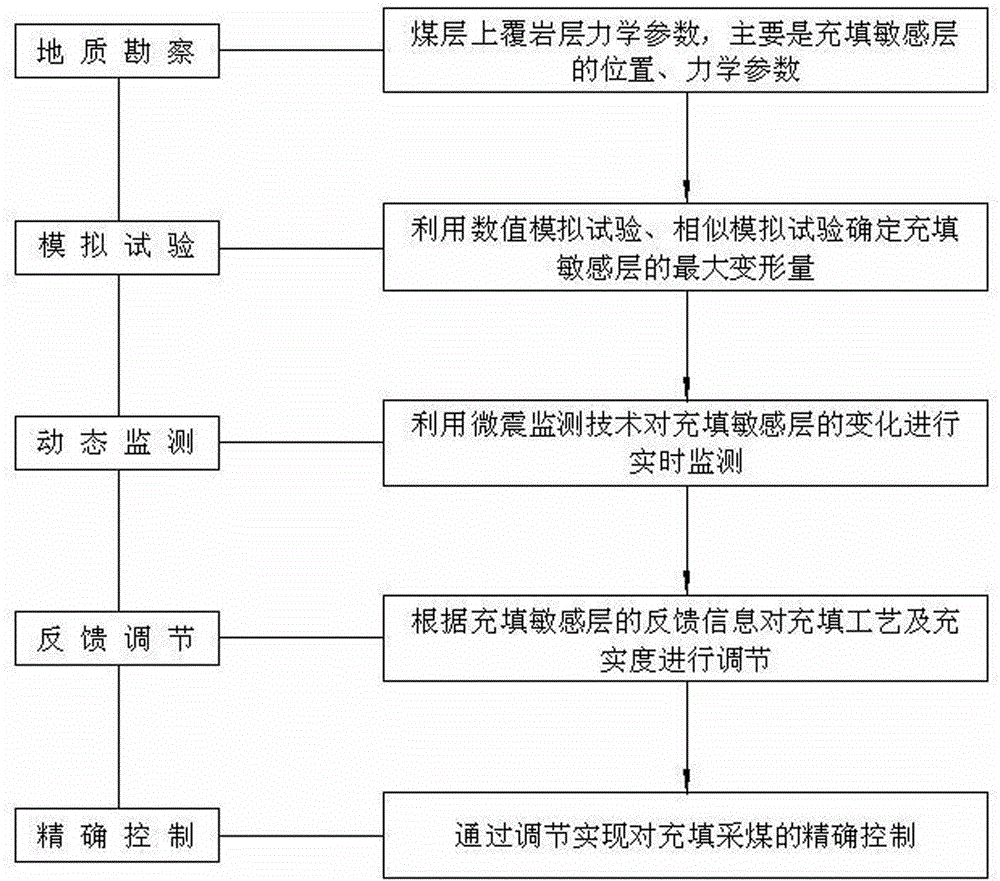

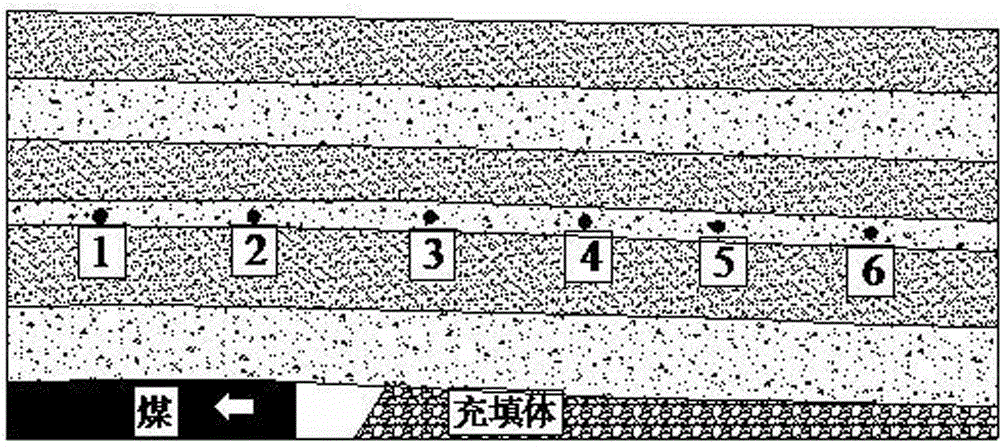

Process for instructing filling mining by observing variation of filling sensitive layer

InactiveCN104564075AEnsure filling rateAchieve economic integrationUnderground miningSurface miningLithologyFilling rate

The invention discloses a process for instructing filling mining by observing the variation of a filling sensitive layer, which relates to the technical field of the filling mining. The process comprises the steps: (1) analyzing and determining the position and lithology of a filling sensitive layer above a filling coal face by utilizing a geophysical prospecting and drilling technology, determining rock mechanics parameters of the filling sensitive layer, and establishing a constitutive relation of the filling sensitive layer; (2) establishing a filling coal mining numerical value analysis model and a similar material simulation analysis model, predicting the relation between the variation of the filling sensitive layer and a surface protection target and a filling body filling rate, and determining maximum deflection of the filling sensitive layer when the required filling effect of the surface protection target is satisfied; (3) observing the variation of the filling sensitive layer in the filling mining process by utilizing a microseism technology in real time, instructing the filling mining in time according to the variation of the filling sensitive layer, and ensuring that the filling rate of filler can enable the deflection of the filling sensitive layer to stay in the calculated maximum value. By adopting the process, the movement of a rock layer can be effectively controlled by utilizing the minimum filling rate.

Owner:HEBEI COAL SCI RES INST

Adjustable filling valve

PendingCN109626303AHigh control precisionMeet filling needsLiquid bottlingMotor driveElectric machinery

The invention provides an adjustable filling valve. A valve body is fixedly arranged on a fixing base, a motor, a lead screw and a sliding block are arranged on the fixing base, the motor drives the sliding block to move through the lead screw, the sliding block is connected with a valve element through a limiting structure, so that when the slide block moves, the end of the valve element is driven to move so as to close or be away from a discharge port of the valve body. According to the adjustable filling valve, the lead screw connected with the motor drives the valve element to move so as to control the opening amplitude of the discharge port of the valve body, so that the filling requirements of different liquids or packaging containers are met; and the valve is simple in structure, but stable in work, and in addition, the control precision of the lead screw is extremely high, so that the working precision and the processing quality can be improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

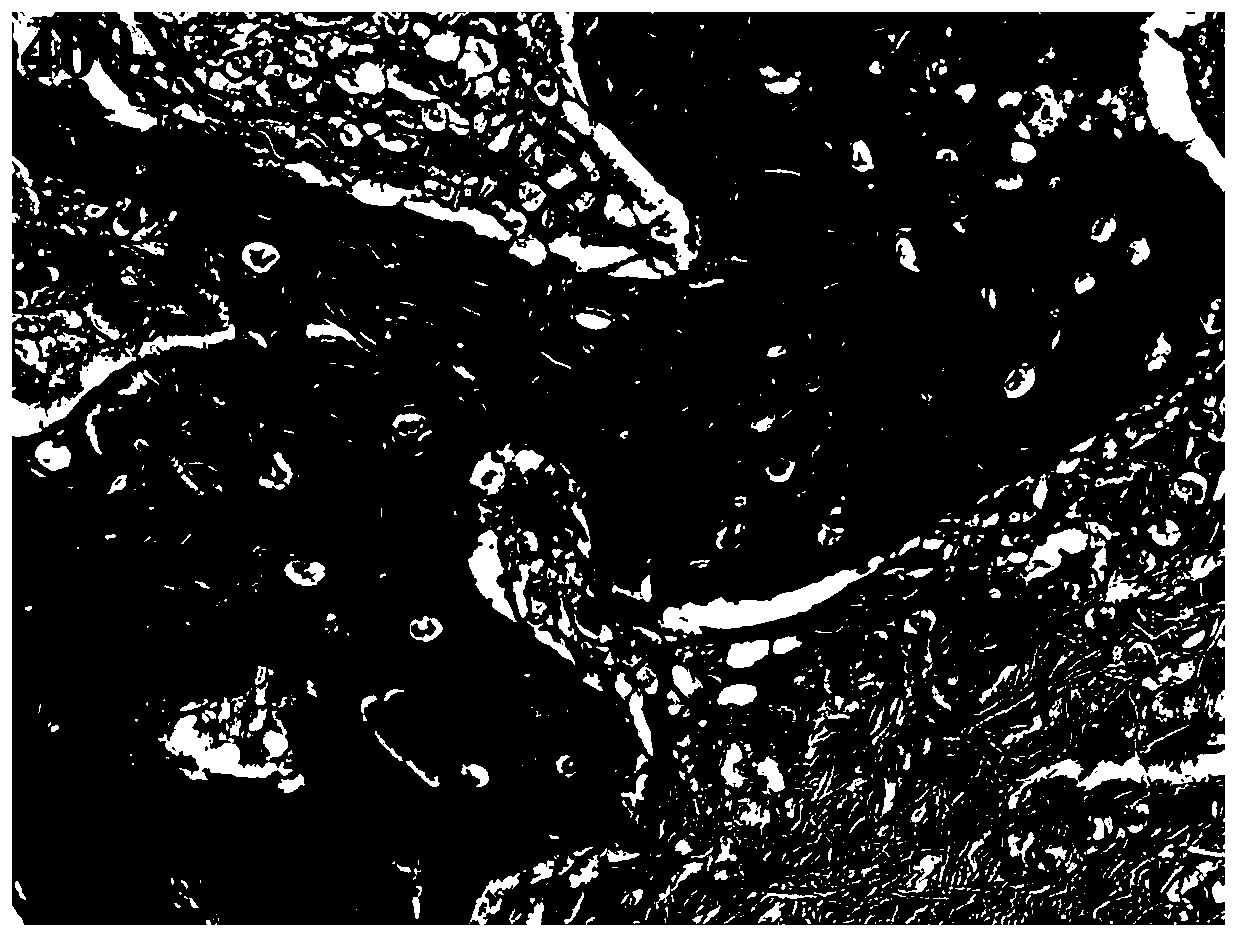

Electrospinning PLGA/PCL fiber membrane composite chitosan sponge stent for oral cavity alveolar bone regeneration and preparation method thereof

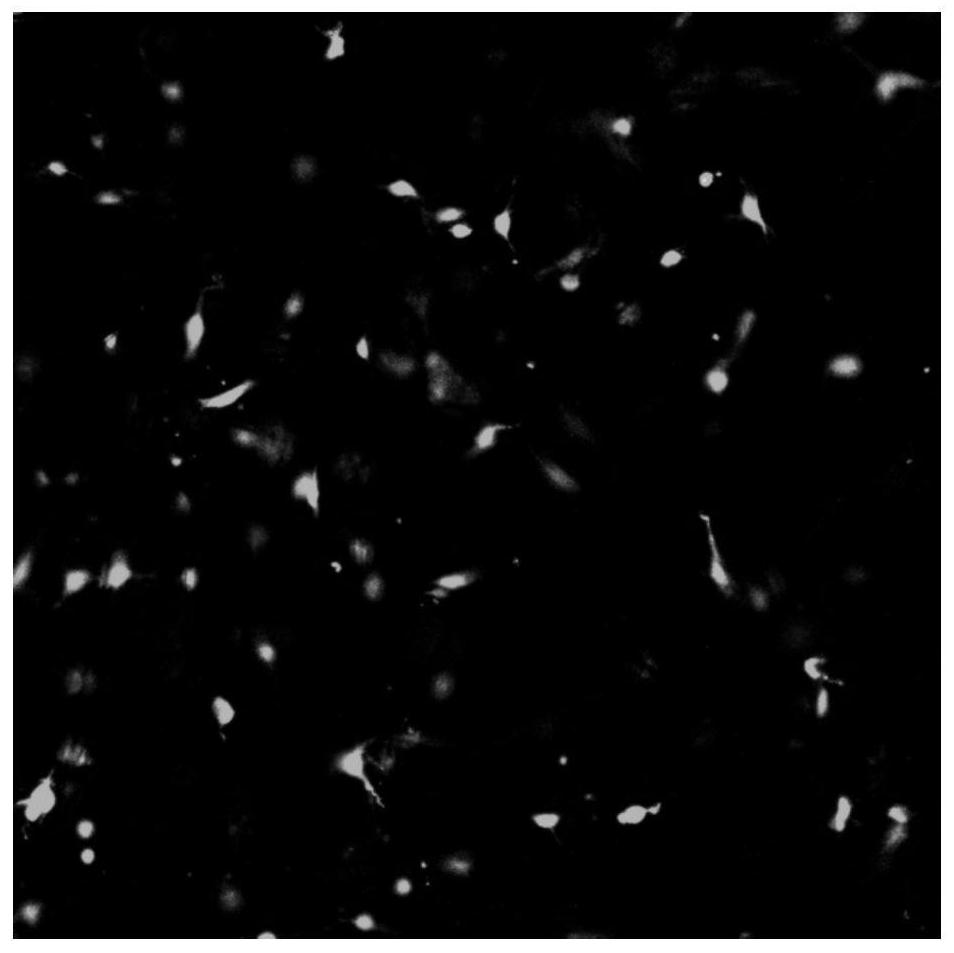

ActiveCN112972777ATightly boundPrevent penetrationPharmaceutical delivery mechanismTissue regenerationPolycaprolactoneCaprolactone

The invention discloses an electrospinning PLGA / PCL fiber membrane composite chitosan sponge stent for oral cavity alveolar bone regeneration. The stent is provided with a compact layer and a loose layer which are tightly combined, the compact layer is an electrospinning polylactic acid-glycolic acid / polycaprolactone (PLGA / PCL) fiber membrane, and the fiber membrane has internal permeability and is composed of disordered fibers; the loose layer is a chitosan sponge and has a loose porous structure; and the porosity of the chitosan sponge ranges from 91.14% to 95.74%. The invention also discloses a preparation method of the electrospinning PLGA / PCL fiber membrane composite chitosan sponge stent for oral cavity alveolar bone regeneration. The stent disclosed by the invention has an integrated compact-loose structure, and the electrospinning compact layer has a supporting effect and can prevent penetration of fibroblasts; and the loose layer has good shape renaturation and water absorption effect, can be combined with blood to form gel, is very suitable for cell ingrowth, and is beneficial to bone tissue regeneration.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

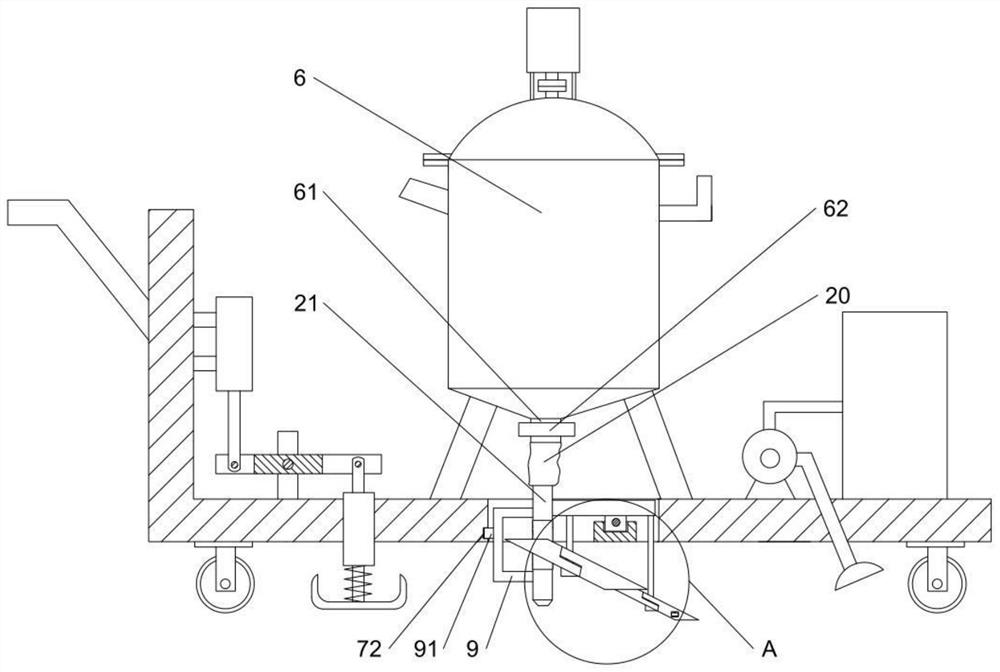

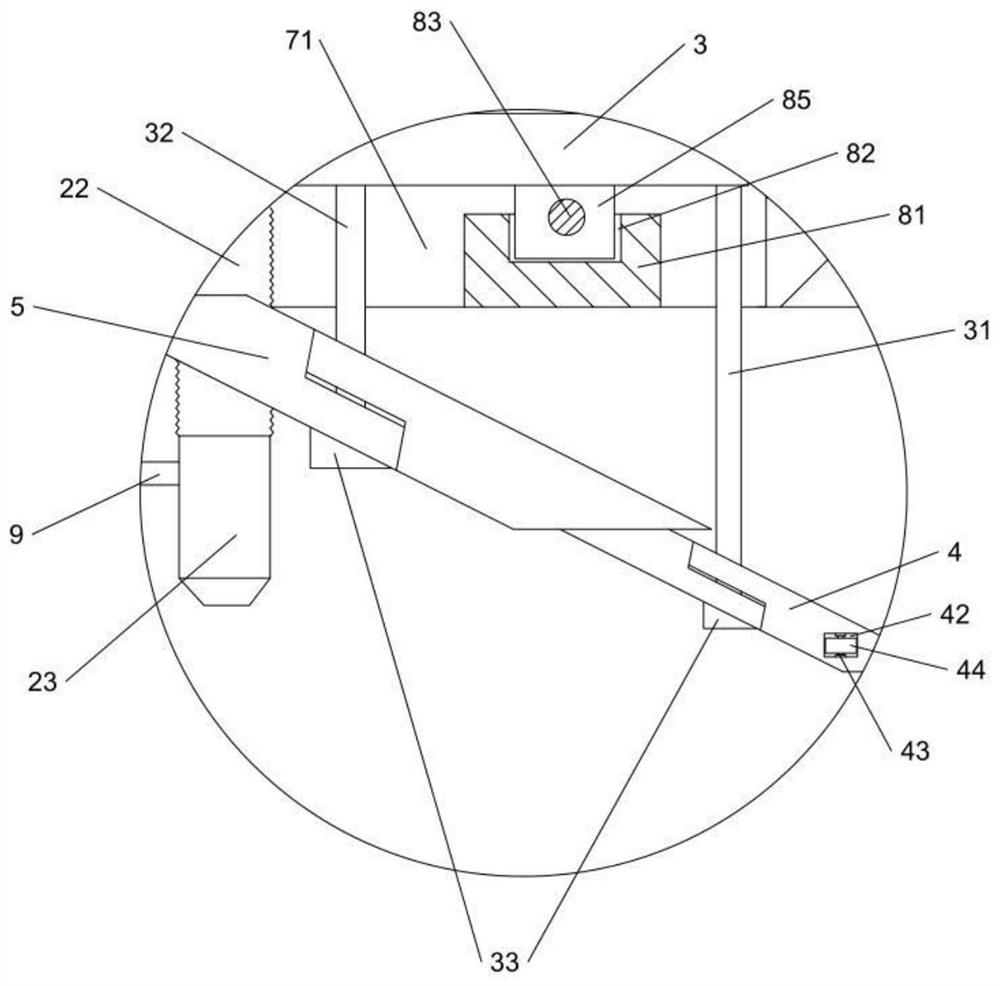

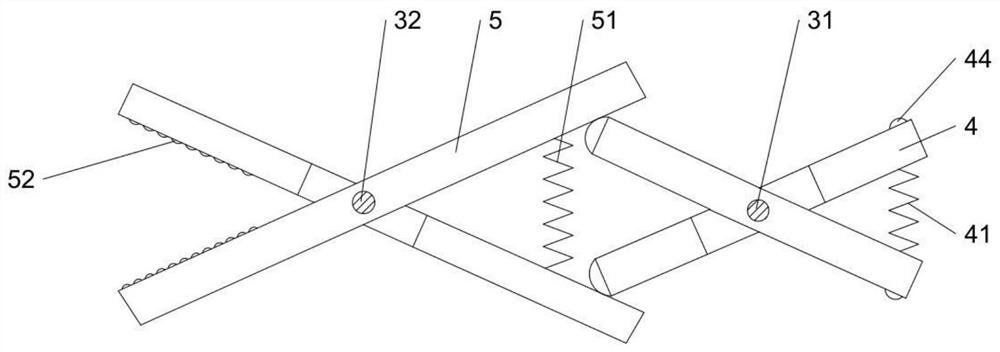

Nasal allergen blocking ointment formula and production equipment thereof

PendingCN114834659ATo achieve the purpose of fillingChange volumeRotary stirring mixersWrapper twisting/gatheringWhite petrolatumGlycerol

The invention discloses a nasal allergen blocking ointment formula and production equipment thereof, and relates to the technical field of nasal anti-allergic ointment. Ointment products of different specifications are prepared in order to facilitate filling; the equipment comprises a preparation tank and a conveying mechanism, a stirring mechanism is arranged in the preparation tank, a filling mechanism is arranged at the bottom of the preparation tank, and the preparation tank is mounted above the conveying mechanism through a first mounting frame; the ointment is prepared from the following raw materials in parts by weight: 65-80 parts of white vaseline, 6.5-8 parts of glycerol monostearate and glycerol distearate, 4-6.5 parts of liquid paraffin, 3-7 parts of PEG40 hydrogenated castor oil, 1-3 parts of menthol and 1-1.5 parts of wool fat. During filling, the carrying frame and the ointment container are jacked up through the jacking mechanism, the bottom end of the filling pipe is inserted into the ointment container, the extrusion plate continues to be jacked upwards, then the elastic bag is extruded, medicine in the elastic bag is extruded into the ointment container, and the purpose of filling is achieved.

Owner:娄飞

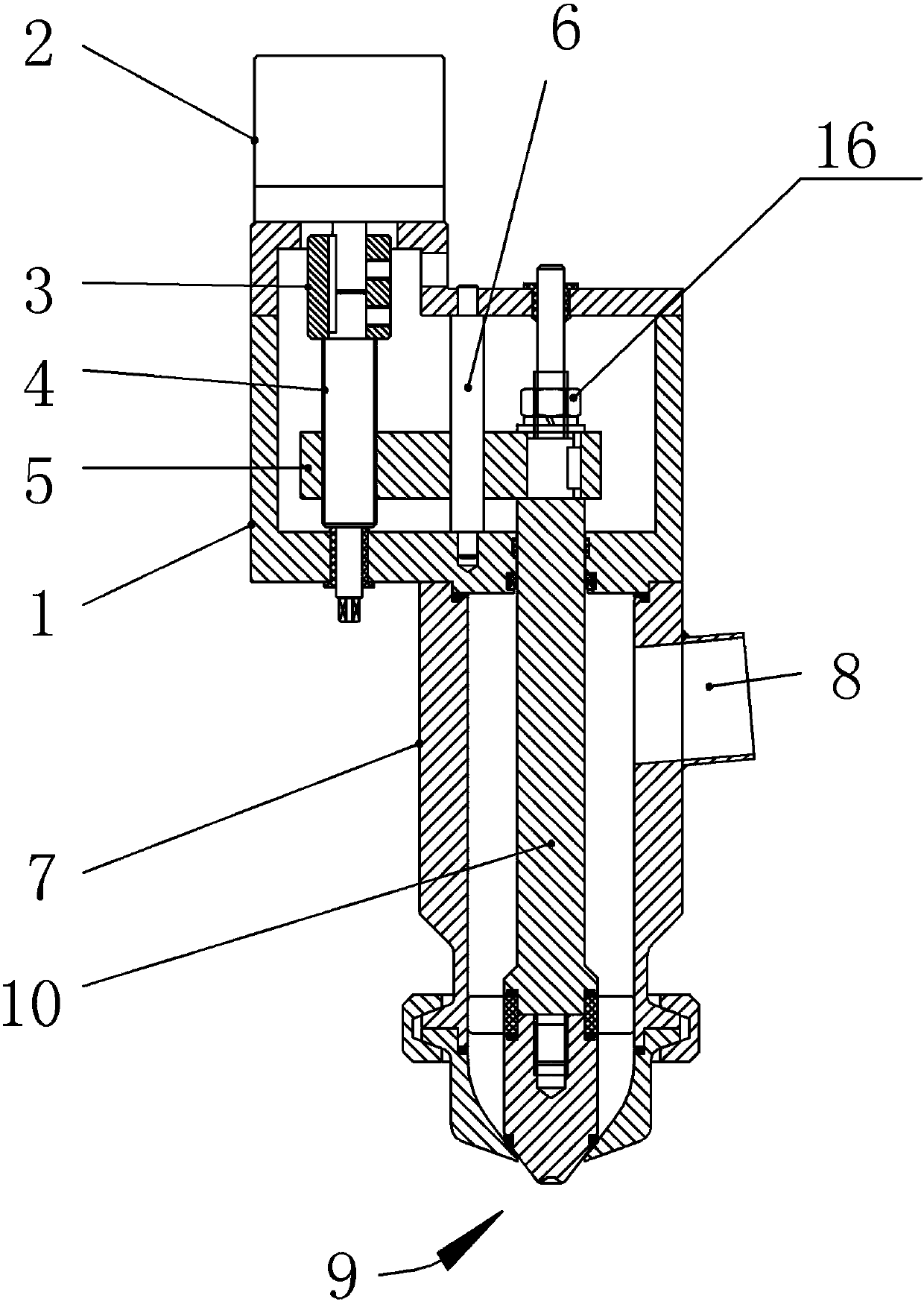

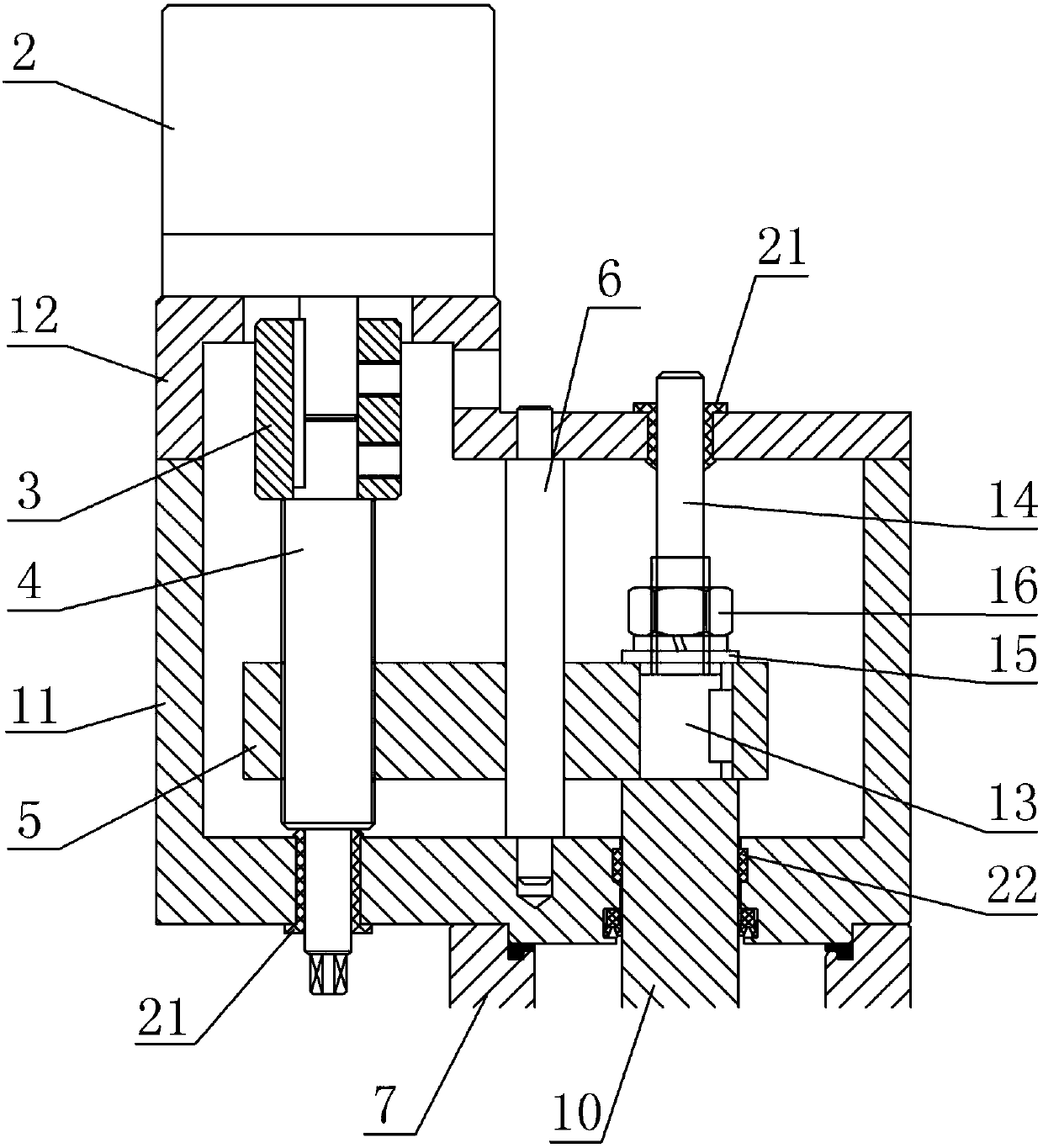

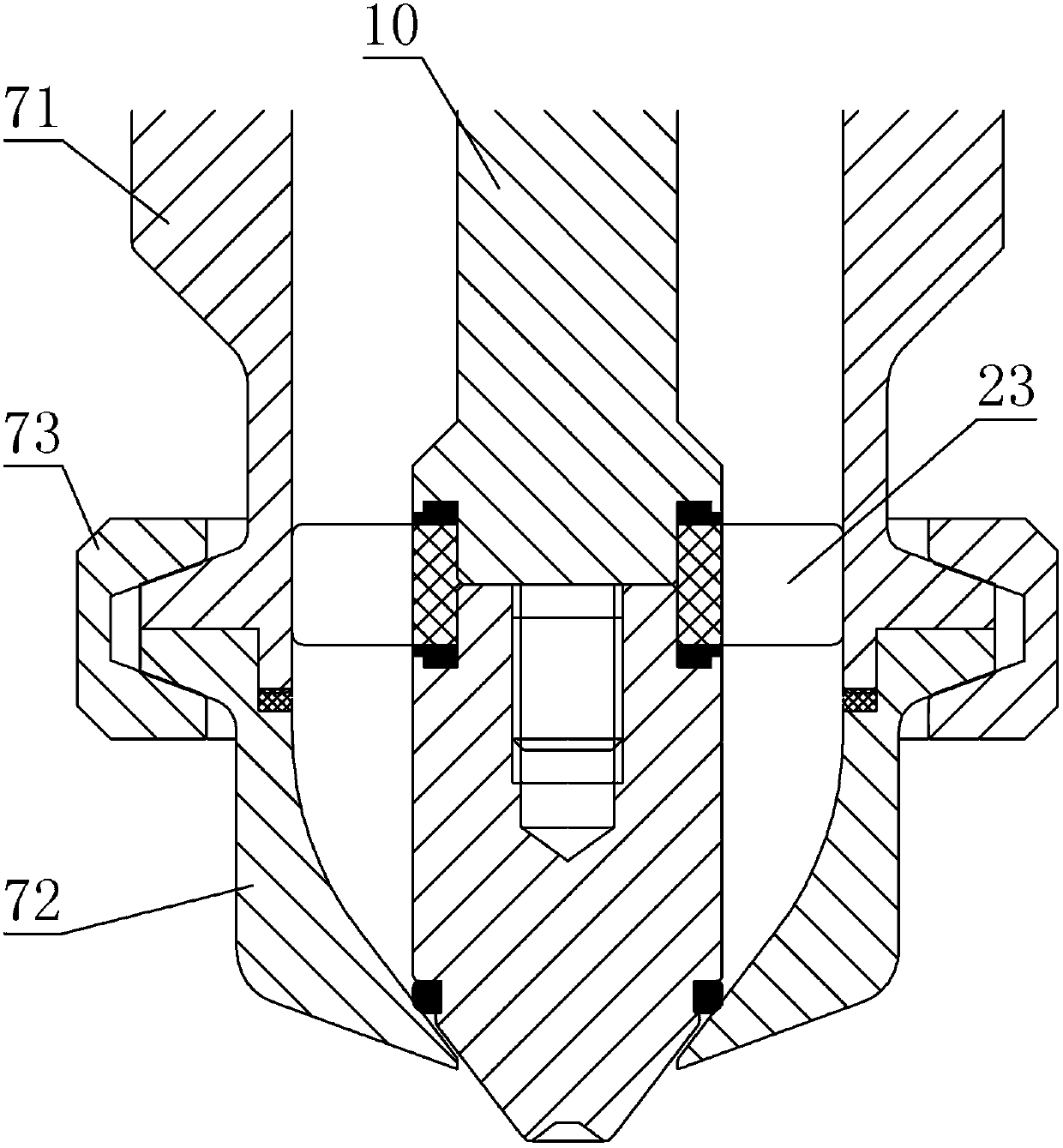

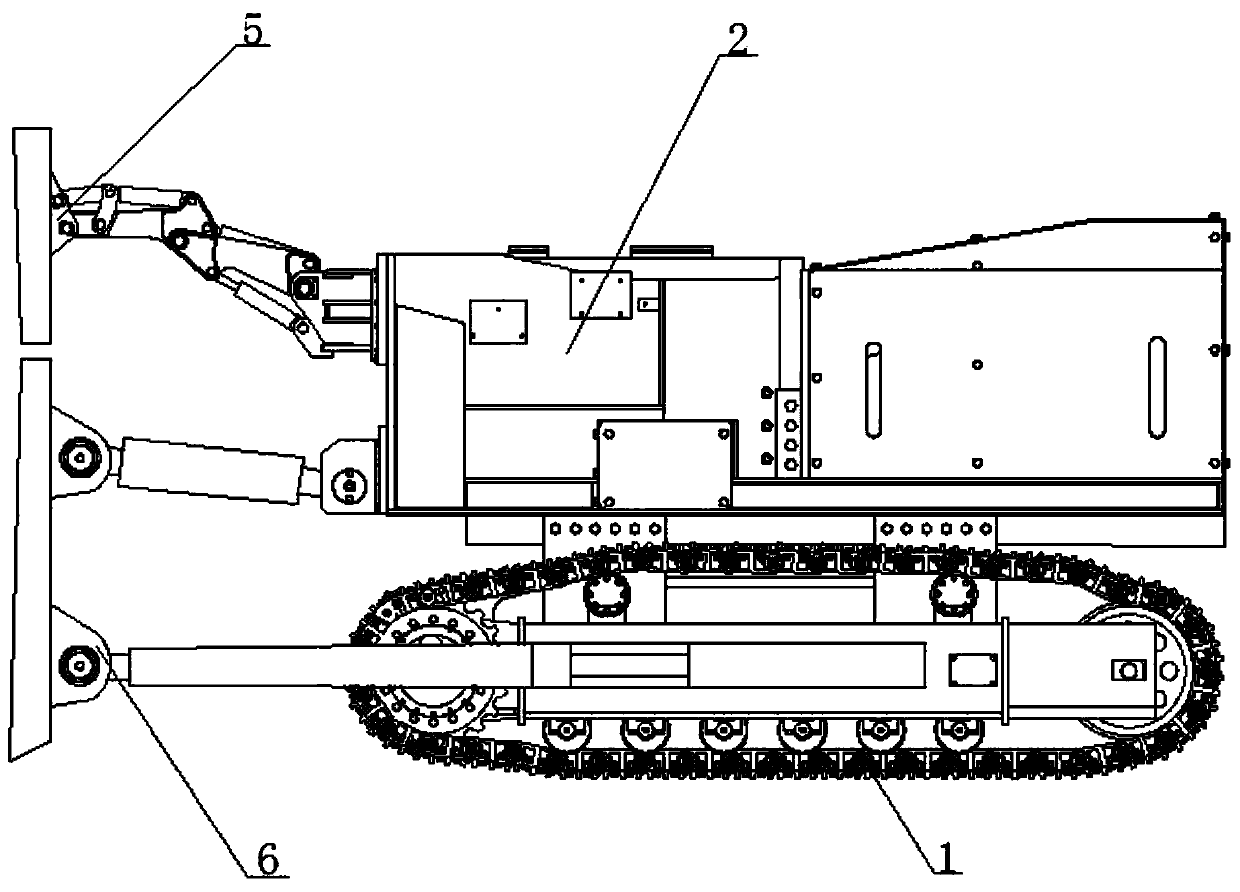

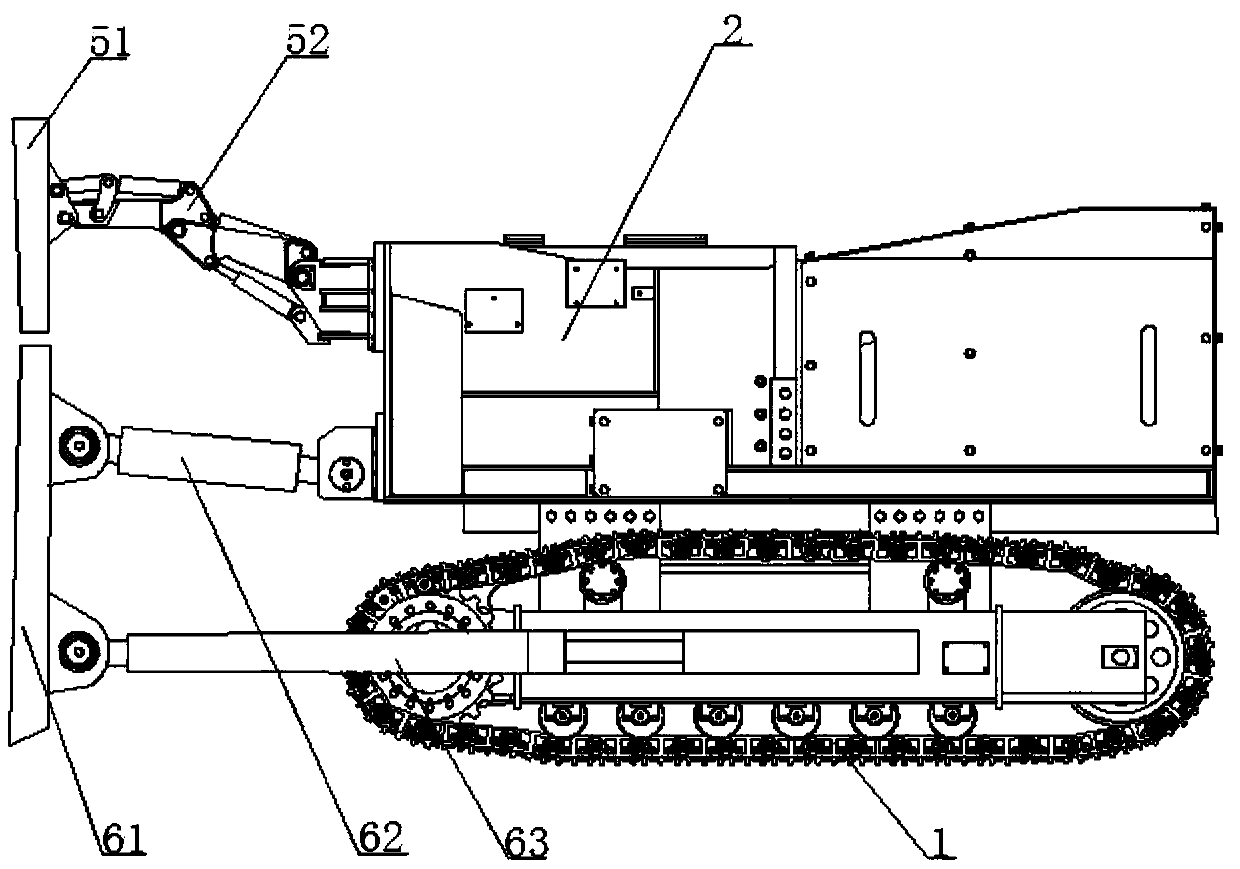

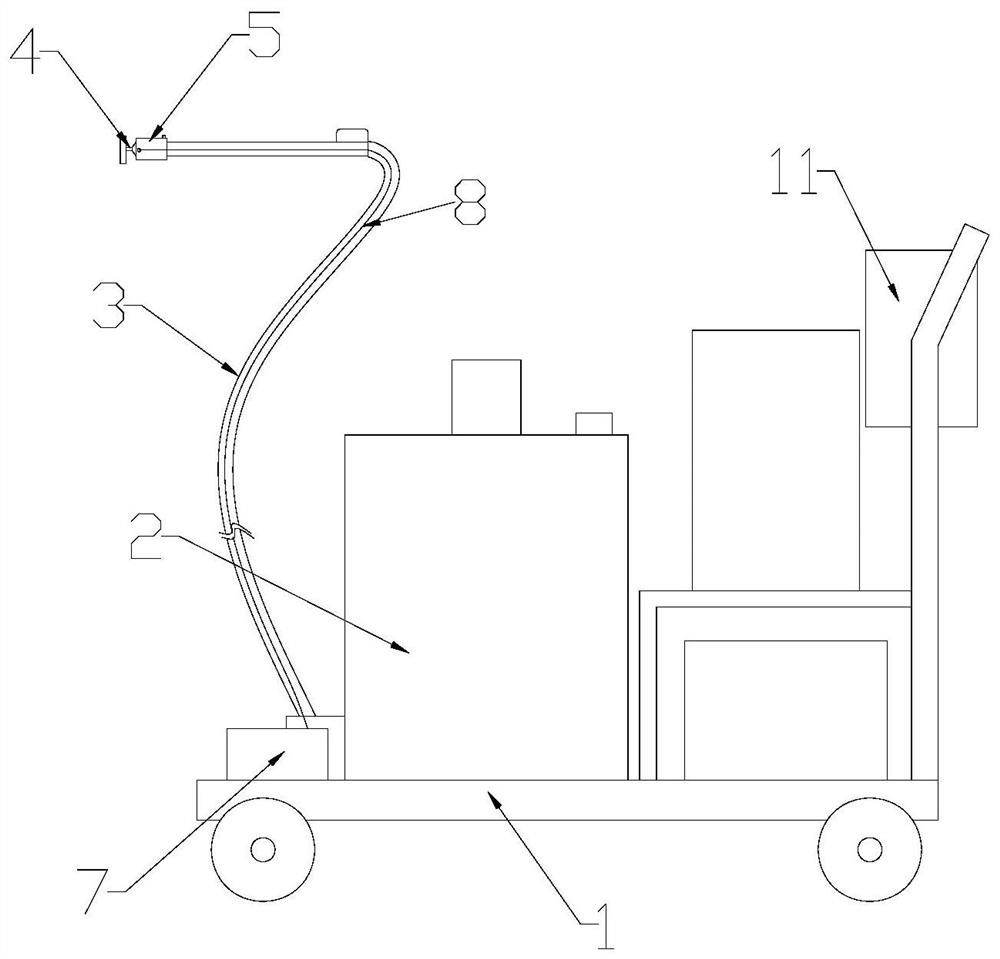

End slope mining goaf filling machine and filling method thereof

ActiveCN111520185AAutomate fillingFulfill filling needsMaterial fill-upMining engineeringHydraulic pump

The invention discloses an end slope mining goaf filling machine and a filling method thereof, and relates to the technical field of coal mine goaf gangue filling. The end slope mining goaf filling machine comprises a crawler walking part, a machine body, a driver control room, a hydraulic pump station, an upper push plate mechanism and a lower push plate mechanism. According to the disclosed theend slope mining goaf filling machine and the filling method thereof, roadways and large-section goaf after open-pit mine end slope mining can be filled, automatic goaf roadway filling is realized, and compacting and solidifying operations on filling materials can be carried out, so that the filling rate of the filling materials is ensured, the top contact rate of the filling materials is improved, the filling effect is enhanced, the problems of uneven filling, roof descending and the like are effectively prevented; and meanwhile, the filling machine is high in maneuverability, can be used incooperation with other conveying and filling equipment for open-pit mine end slope mining, further saves the filling cost, improves the filling effect, and has high innovativeness and wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Expressway pavement crack repairing device

ActiveCN113389122AAvoid lostMeet filling needsClimate change adaptationRoads maintainenceSprayerArchitectural engineering

The invention discloses an expressway pavement crack repairing device. The device comprises a hard pipe of which the two ends are respectively communicated with a feeding hole of an asphalt conveying device and an elastic pipe, wherein the other end of the elastic pipe is connected with a sprayer, a connecting plate is fixed to the side wall of the hard pipe, and a first shaft and a second shaft are arranged on the two sides of the bottom of the connecting plate respectively. The first shaft is sleeved with and hinged to two first clamping plates which are arranged in an X-shaped crossed mode. And a first spring is fixed between the inner plate surfaces of the lower sides of the two first clamping plates. The second shaft is sleeved with and hinged to two second clamping plates which are arranged in an X-shaped crossed mode. And the outer plate surfaces of the upper sides of the two first clamping plates are clamped between the inner plate surfaces of the lower sides of the two second clamping plates. The elastic pipe is clamped between the upper side inner plate faces of the two second clamping plates, and a second spring is fixed between the lower side inner plate faces of the two second clamping plates. When a pavement crack is subjected to crack pouring repair, the change of the flow of asphalt sprayed by the spray head can be correspondingly adjusted according to the change of the width of the crack so as to implement targeted filling.

Owner:中铁建新疆京新高速公路有限公司

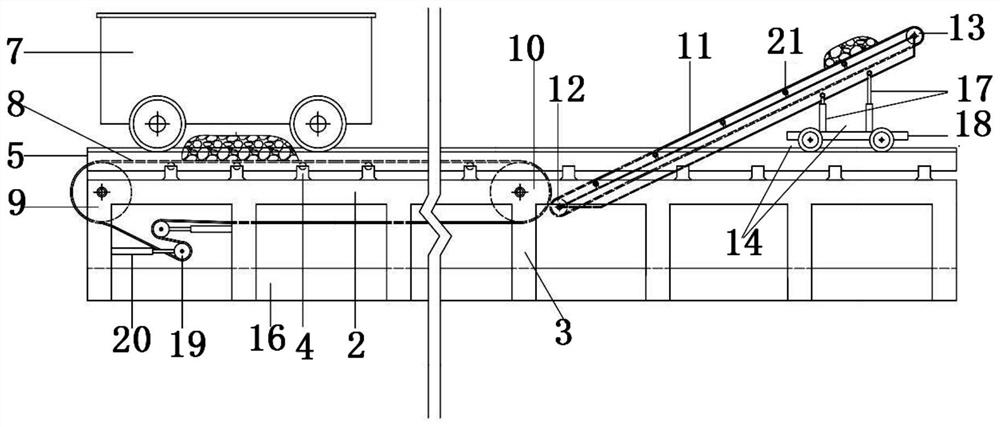

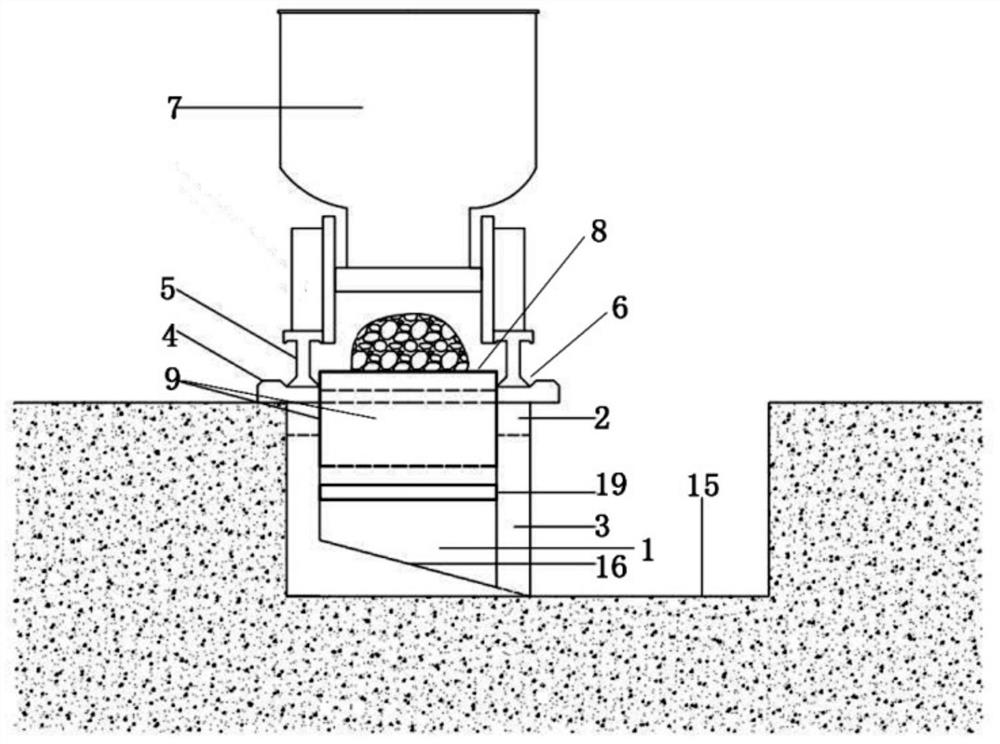

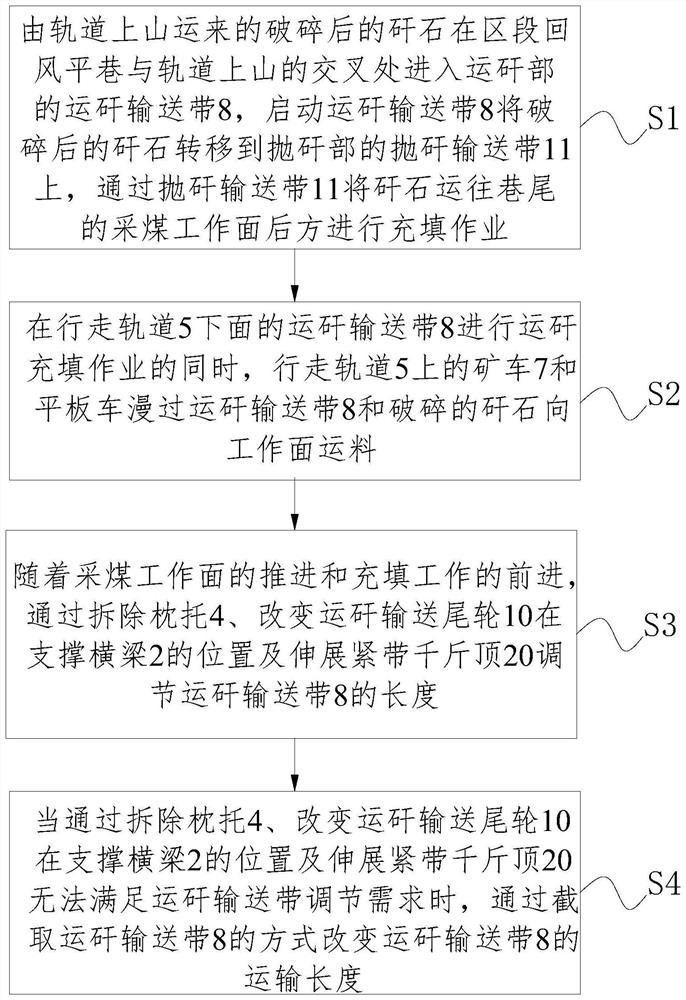

Gangue transporting and backfilling system and method for laying transmission rubber belt under rail

ActiveCN112459833AImprove backfill efficiencyLarge volumeMaterial fill-upMechanical engineeringGeotechnical engineering

The invention relates to a gangue transporting and backfilling system and method for laying a transmission rubber belt under a rail. A sleeper support is fixed to the upper end of a support cross beam, a mounting groove is formed in the upper surface of the sleeper support, and a walking rail is fixed to the interior of the mounting groove; a gangue transporting conveying head wheel is located atthe roadway head of an air return roadway and is fixed between two columns of support cross beams; a gangue transporting conveying tail wheel is located at the roadway tail of the air return roadway and is fixed between the two columns of support cross beams; a gangue transporting conveying belt is connected between the gangue transporting conveying head wheel and the gangue transporting conveyingtail wheel, and the gangue transporting conveying belt reciprocates along the gangue transporting conveying head wheel and the gangue transporting conveying tail wheel; a gangue throwing conveying head wheel is located on one side of the gangue transporting conveying tail wheel, and a gangue throwing conveying belt reciprocates along the gangue throwing conveying head wheel and a gangue throwingconveying tail wheel; and a gangue throwing adjusting assembly is connected to the lower end of a gangue throwing part, and the bottom of the gangue throwing adjusting assembly is arranged above the walking rail. According to the gangue transporting and backfilling system and method, gangue can be continuously conveyed to the rear part of a coal face for backfilling operation, so that the backfilling efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

Barrier-type contraceptive for women

Owner:王晓成

A kind of asphalt pavement filling device and method

ActiveCN112878163BEasy to controlAvoid issues like underfillRoads maintainenceCoaxial lineEngineering

The present invention provides an asphalt pavement joint filling device and method. The asphalt pavement joint filling device includes a vehicle frame, which is provided with a hot-melt box and a spray gun. The spray gun includes a delivery pipe and a nozzle. The outlet of the melting tank is connected, and the other end is connected to the nozzle. A connection assembly with adjustable inner diameter is arranged between the delivery pipe and the nozzle. The connection assembly includes an outer pipe, and a coaxial elastic hose is arranged inside the outer pipe. The elastic hoses communicate with each other, and an inflatable chamber is formed between the elastic hose and the outer tube. An air pump is also arranged on the frame, and the air pump is connected with the inflatable chamber through an air delivery pipe. A control valve is arranged at the air outlet. The invention can adjust the inner diameter of the elastic hose in real time according to the depth of the crack, and adjust the pressure when the nozzle is discharged, so as to meet the needs of filling cracks with different crack depths.

Owner:董方

Machine table for wafer cleaning machine

ActiveCN112309950AReasonable distributionHeight position adjustableSemiconductor/solid-state device manufacturingEngineeringMachine

Disclosed is a machine table for a wafer cleaning machine. The machine table comprises a rotating base, a protective gas pipeline is inserted into the center of the rotating base, a bearing sleeve isfixed to the upper end of the rotating base, an outer groove and an inner groove are formed in the bearing sleeve, an annular pressing pad and an air bag ring are installed in the inner groove, and the air bag ring is communicated with an air pipe with an opening valve; an air outlet groove is formed in the center of the rotating base and provided with a buffer baffle with air holes in the air outlet direction of the protective gas pipeline. The machine table is reasonable in structural design, the bearing sleeve is optimized, the inner groove is additionally formed on the basis of a traditional outer groove, the annular pressing pad and the air bag ring are installed in the inner groove, the air bag ring serves as a hoop after being inflated, a wafer is effectively clamped in the rotatingbase, and smooth cleaning is guaranteed; moreover, the height position of a rectifying baffle is adjustable, air holes are reasonably distributed, and the protective gas filling requirement is met.

Owner:上海宏轶电子科技有限公司

Method of Releasing the Stress of the Triangular Suspended Roof by Blasting the Island Body

ActiveCN111042815BEnsure safetyFall in timeDisloding machinesMaterial fill-upStress concentrationMining engineering

The invention discloses a method for blasting an island body to release the stress of a triangular suspended roof region. The method comprises the following blasting steps that firstly, drilling holesare distributed according to the area of the triangular suspended roof region, and the drilling holes at least comprise main drilling holes arranged in the three angular positions and the central position of the triangular suspended roof region respectively, and a plurality of adjusting drilling holes arranged in other positions in the triangular suspended roof region; secondly, carbon dioxide blasters are installed inside the main drilling holes, and the adjusting drilling holes are vacant inside to serve as free surface vacant holes; and finally, all the carbon dioxide blasters inside the main drilling holes are initiated. The method for blasting the island body to release the stress of the triangular suspended roof region is safe and reliable, is not influenced by gas accumulation in agoaf, and is particularly suitable for the application to a highly gassy mine, the blasting fragment size is not limited, construction is simple and convenient, the area of the triangular suspended roof region can be reduced effectively in time, stress concentration in the goaf is weakened or eliminated, a suspended roof in the goaf is timely stripped and collapsed, the goaf at the middle upper part is filled, and safe and smooth production of a working face is guaranteed.

Owner:CENT SOUTH UNIV

Automatic filling machine

The invention discloses an automatic filling machine, the automatic filling machine comprises a rack and further comprises filling mechanisms, pushing mechanisms, a pressing mechanism, a distributingmechanism and a supporting mechanism which are installed on the rack, the filling mechanisms are installed on the pushing mechanisms, the plurality of pushing mechanisms are arranged, the distributingmechanism is provided with a distributing cavity, the distributing cavity is provided with a plurality of cavities, a distributing conveying channel is arranged in the middle of the distributing cavity, the distributing conveying channel is provided with a plurality of channels, the pressing mechanism is installed on the rack and is arranged above the distributing mechanism and opposite to the distributing conveying channel, the bottom of the distributing mechanism right faces the top end of the supporting mechanism, a filling bottle can be placed at the top end of the supporting mechanism tobe in butt joint with the bottom of the distributing mechanism and used for receiving materials conveyed by the distributing conveying channel, and the filling mechanisms, the pushing mechanisms, thepressing mechanism and the supporting mechanism are all connected with a control box installed at the bottom of the rack. According to the automatic filling machine, quantitative filling of differentoil mixtures is achieved, and different mixed materials can be clearly layered and are not mixed with one another.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Fiber-based three-dimensional porous composite material for bone repair, its preparation method and molded product

ActiveCN107137773BSignificant osteogenic effectMeet filling needsTissue regenerationProsthesisFiber diameterCompressive strength

The invention provides a fiber-based three-dimensional porous composite material for bone repair and a preparation method thereof and a molded product. The fiber-based three-dimensional porous composite material comprises micronano fiber powder and a binder, wherein the particle diameter of the micronano fiber powder is 10-500 micrometers, the diameter of fiber forming the micronano fiber powder is 0.1-100 micrometers, and the micronano fiber powder is evenly dispersed in the binder; the binder comprises biodegradable and self-curable inorganic components; the fiber-based three-dimensional porous composite material comprises, by mass, 5-50% of the micronano fiber powder, the porosity of the fiber-based three-dimensional porous composite material is 30-85%, and the compressive strength is 1-15 MPa. A constructed fiber-based three-dimensional connected porous scaffold is simple in preparation method and has a micronano fiber structure, so that the scaffold has a remarkable induced osteogenesis effect; the constructed fiber-based three-dimensional connected porous scaffold can better meet the filling demand of bone defect sites and can provide better mechanical properties.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH +1

Method for cleaning ALD source steel cylinder

PendingCN113818026AEasy to cleanSimplify subsequent processing stepsCleaning using liquidsAlkaneOrganic solvent

The invention discloses a method for cleaning an ALD source steel cylinder. The method for cleaning the ALD source steel cylinder comprises the following steps: (1) in a water-free and oxygen-free glove box, adding anhydrous alkane into the ALD precursor source steel cylinder for cleaning; (2) fully filling the steel cylinder cleaned in the step (1) with the anhydrous alkane, and carrying out ultrasonic cleaning; (3) moving the steel cylinder out of the glove box, and cleaning with an organic solvent-alkali system, an acid solution system and an ultrapure water system in sequence; and (4) fully filling the cleaned steel cylinder with ultrapure water, standing, carrying out ICP-OES detection, and drying for later use after the detection is qualified. By means of the cleaning method, precursors, oil substances, oxide impurities and metal impurity particles in the ALD precursor source steel cylinder can be cleaned, the ALD source filling requirement is met, the method is simple to operate, the cleaning process is safe and easy to operate, the cleaning raw materials are low in cost and short in period, and the requirements for purifying, filling and producing the steel cylinder can be rapidly provided.

Owner:苏州源展材料科技有限公司

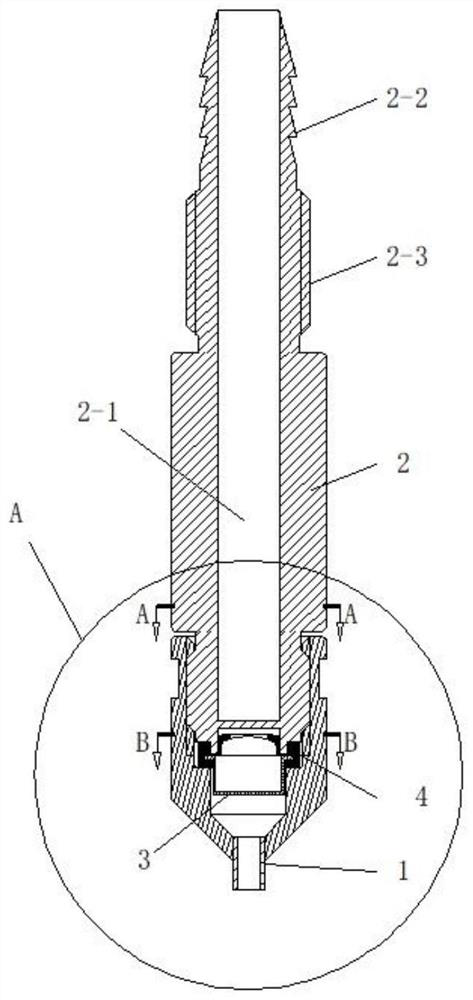

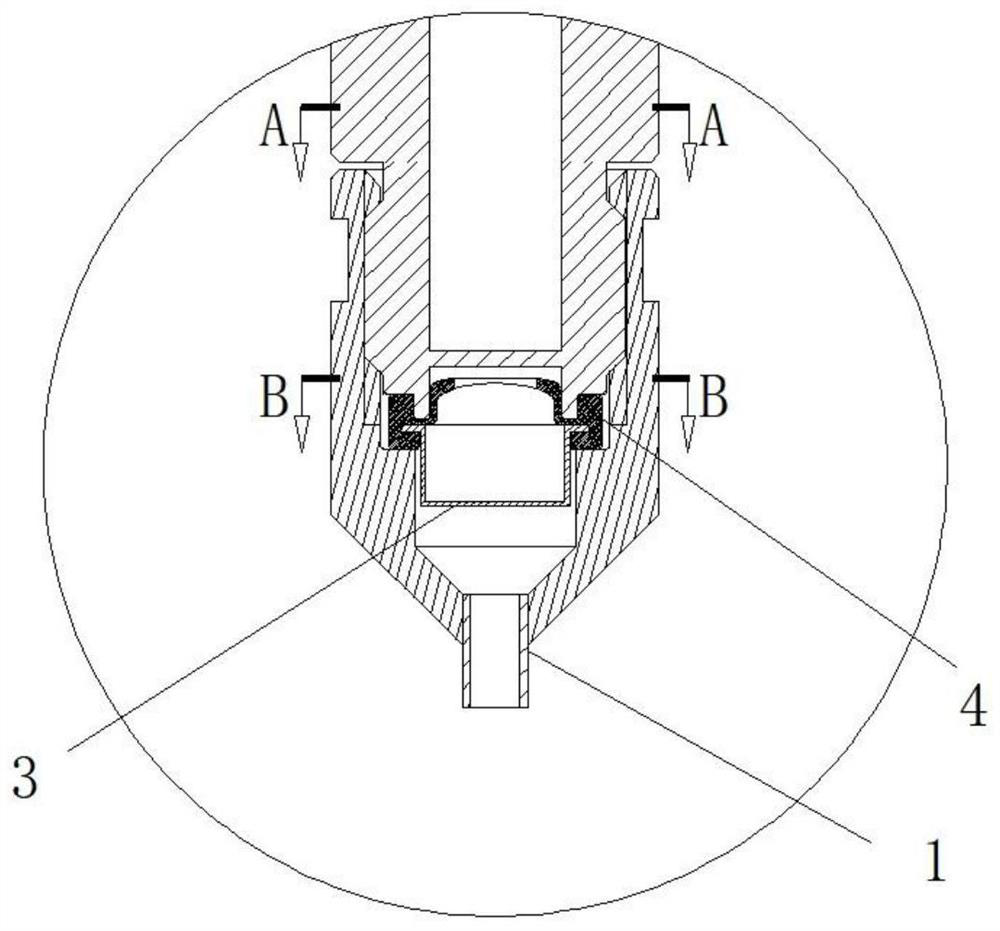

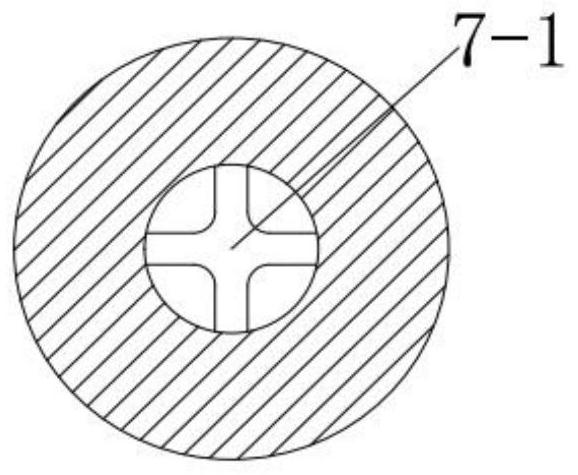

Drip-proof filling needle for filling machine

PendingCN113104799AMeet filling needsSolve the hourglassLiquid bottlingSilica gelMechanical engineering

The invention discloses a drip-proof filling needle for a filling machine, and belongs to the technical field of filling equipment. The drip-proof filling needle comprises a needle cylinder and a needle head, wherein the needle cylinder and the needle head are connected into a whole, the needle cylinder and the needle head are connected together, a filling cavity is arranged in the needle cylinder, a silica gel valve is arranged at the joint of the needle cylinder and the needle head, and a cross-shaped opening is formed in the top of the silica gel valve. After filling is completed, the cross-shaped opening of the silica gel valve deforms and returns to the original state to form sealing, a discharging port is formed in the lower portion of the filling cavity, a pipe connector is arranged on the upper portion of the needle cylinder and used for being connected with a feeding pipe for feeding, and a fixing thread is arranged on the lower portion of the pipe connector and used for being fixedly connected with the filling machine. In order to improve the sealing communication effect, the discharging port is in a cross shape, and the discharging port is correspondingly communicated with the cross-shaped opening in the silica gel valve. The technical problems that existing equipment needs to be cleaned and filling liquid is wasted in the production process are solved, and the filling liquid filling device is mainly applied to the filling machine for filling liquid filling.

Owner:连云港宝畅流体输送设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com