Method of Releasing the Stress of the Triangular Suspended Roof by Blasting the Island Body

A triangular and isolated technology, which is used in earth-moving drilling, gas discharge, mining equipment, etc., can solve the problems of difficult treatment of steeply inclined hard roof coal seams, increased safety risks of overhanging surrounding rocks, frequent equipment in and out, etc., and achieves technical construction. Simple and safe, reducing the area of the suspended ceiling, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

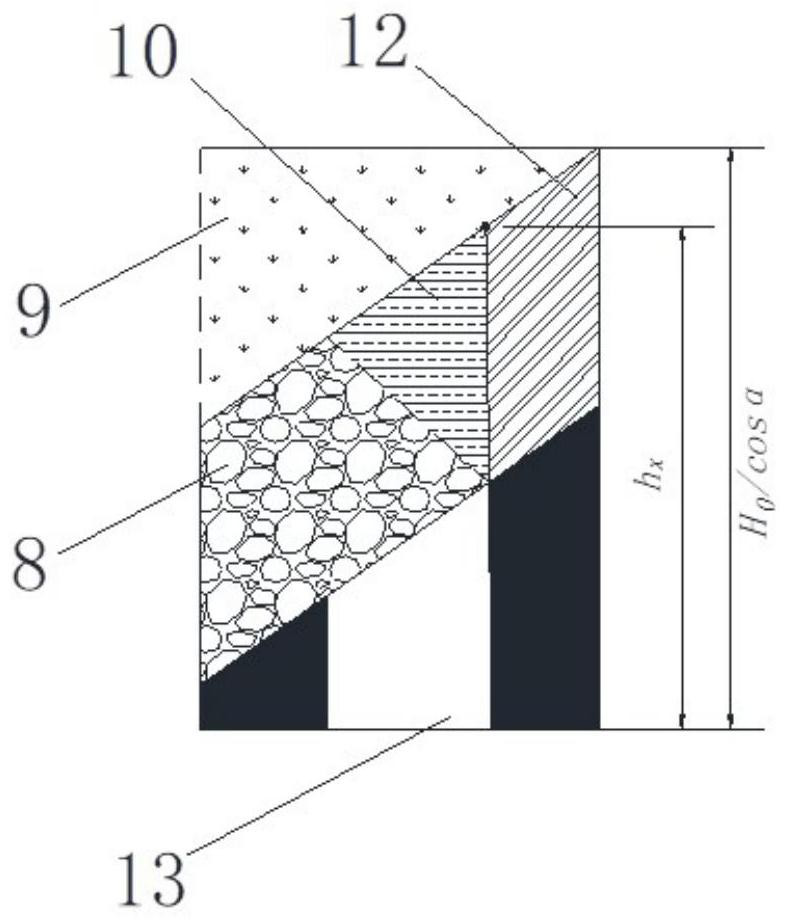

[0031] The structure of the triangular overhang area is as follows figure 1 As shown, the three surfaces of the triangular suspended roof area 10 are respectively connected with the overlying rock 9 , the goaf 8 and the upper deep overlying rock 12 .

[0032] This example provides a method for releasing the stress in the triangular suspended roof region by blasting the island body. The specific steps are as follows:

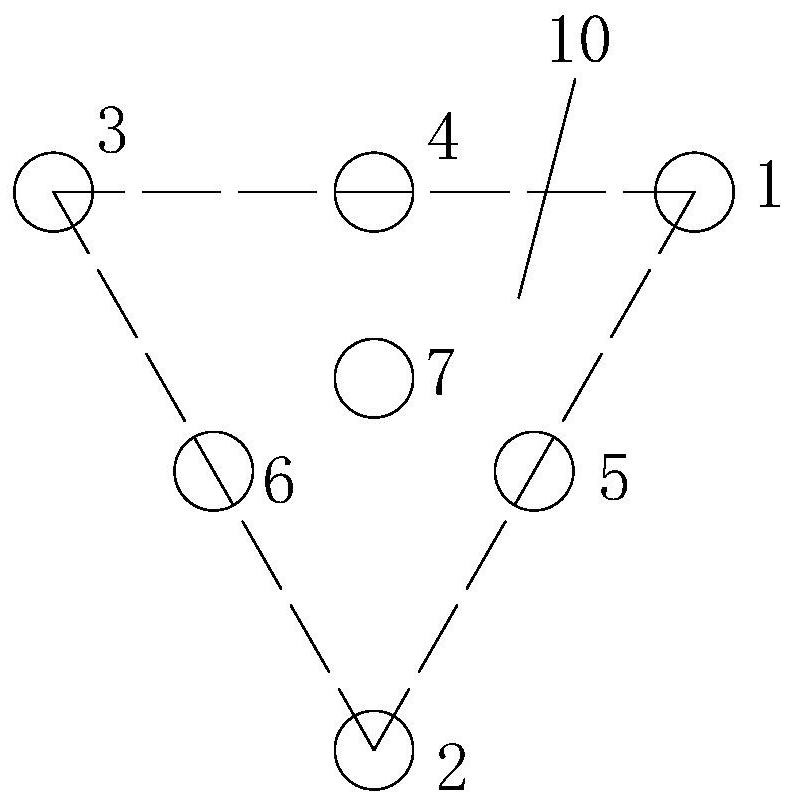

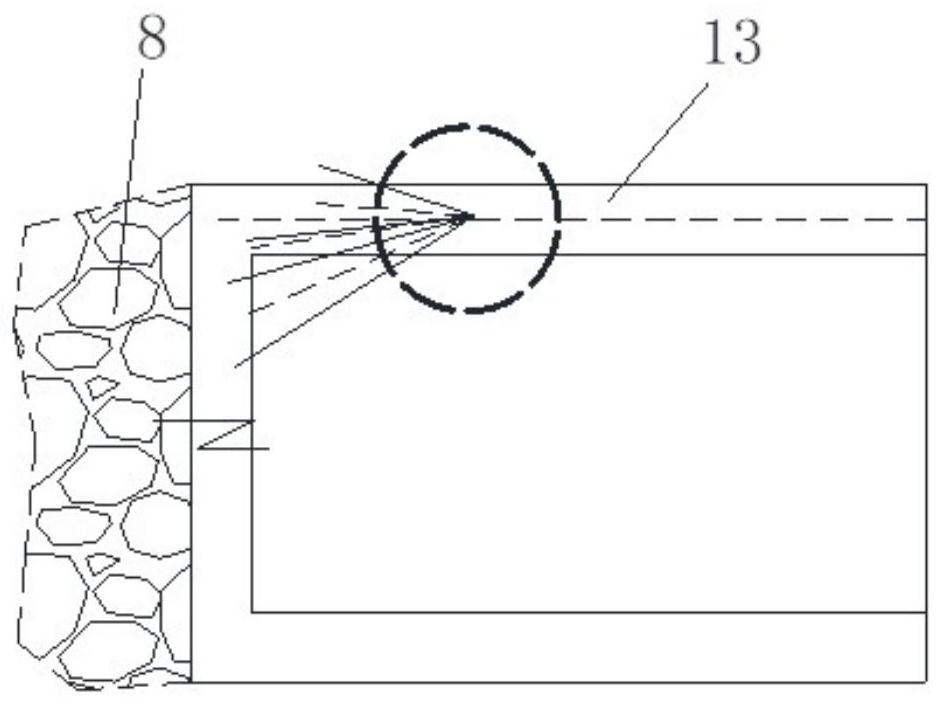

[0033] combine figure 1 The size of the rock mass area in the triangular suspended top area shown in , reasonably arrange the blasting drill holes in the air return trough 13, the drill holes include the main drill hole and the adjustment drill hole, wherein the main drill hole is the blast hole, and the adjustment drill hole The interior is only used as a free surface hole, and the main drill holes are correspondingly distributed in the three corner positions and the center position of the triangular suspended roof area, respectively figure 2 The old top cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com