Drip-proof filling needle for filling machine

A filling machine and anti-drip technology, applied in the field of machinery and equipment, can solve the problems of difficult gas, increase production costs, affect the normality of equipment, etc., and achieve the effects of low production cost, production cost saving, and production cleaning cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

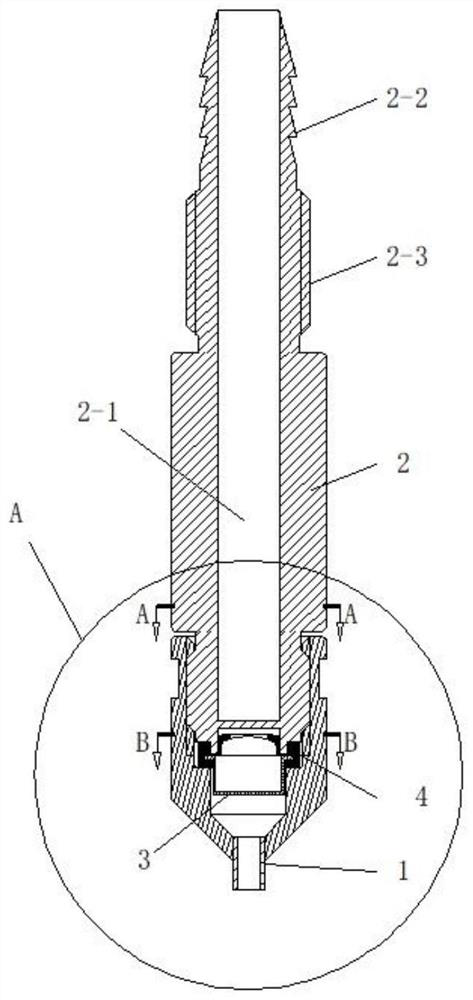

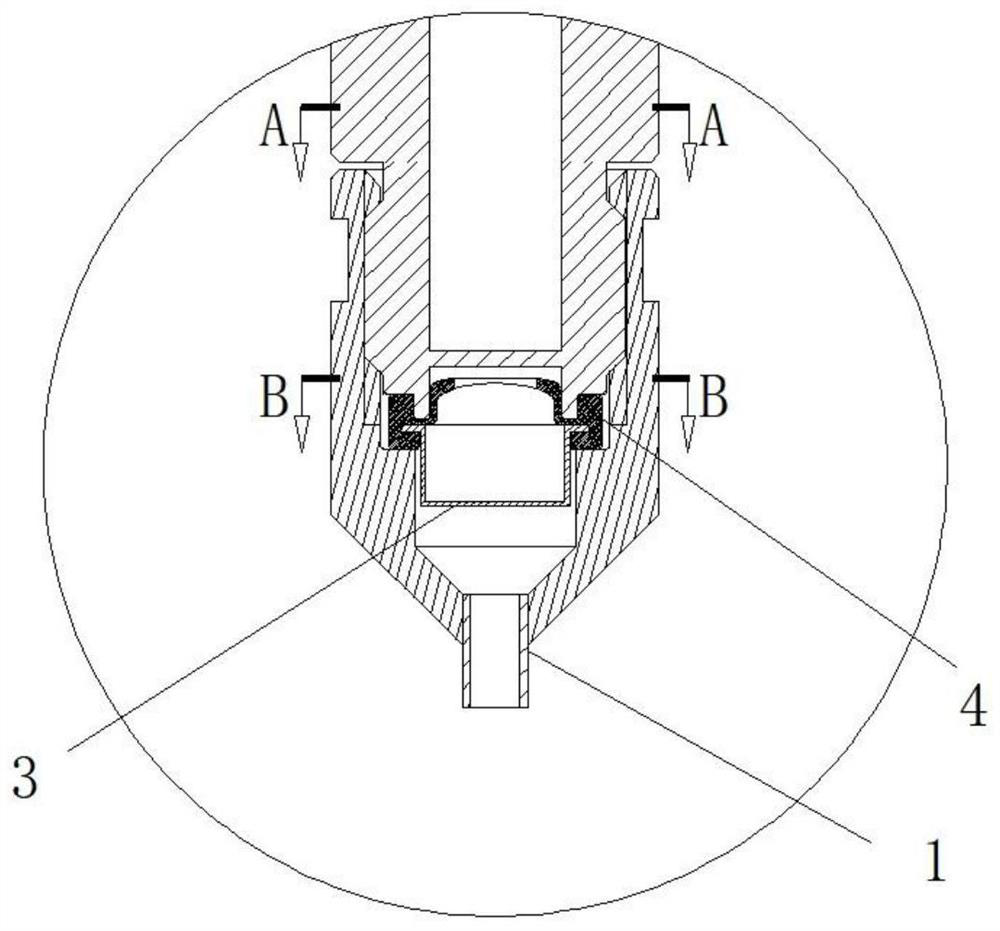

[0021] see Figure 1-Figure 5 , the present invention provides a technical solution:

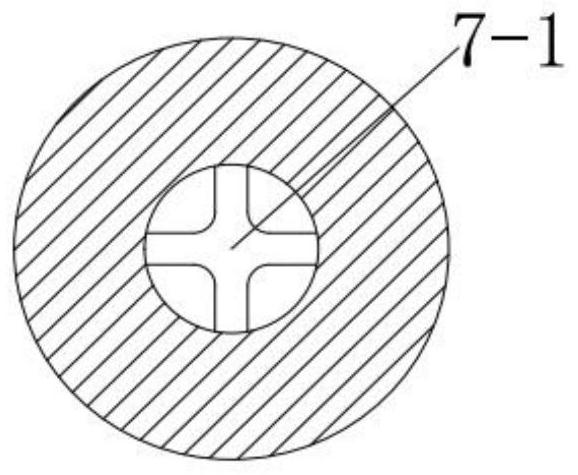

[0022] An anti-drip filling needle for a filling machine, characterized in that it includes a syringe 2 and a needle 1, the syringe 2 and the needle 1 are connected to form a whole, and the syringe 2 is provided with a filling chamber 2-1, the connection between the syringe 2 and the needle 1 is provided with a silicone valve 4, the top of the silicone valve 4 is provided with a cross-shaped opening 4-1, and the lower part of the filling chamber 2-1 There is a discharge port 2-1-1, the upper part of the syringe is provided with a pipe joint 2-2, the lower part of the pipe joint 2-2 is provided with a fixed thread 2-3, and the fixed thread 2-3 is used to connect with the filling Installed and fixedly connected, the shape of the discharge port 2-1-1 is a "cross" structure, and the discharge port 2-1-1 is connected to the cross-shaped opening 4-1 on the silica gel valve 4. Corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com