A kind of asphalt pavement filling device and method

A technology for asphalt pavement and joint filling, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as unfavorable and affecting construction efficiency, and achieve the effects of improving efficiency, avoiding deep cracks, and increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

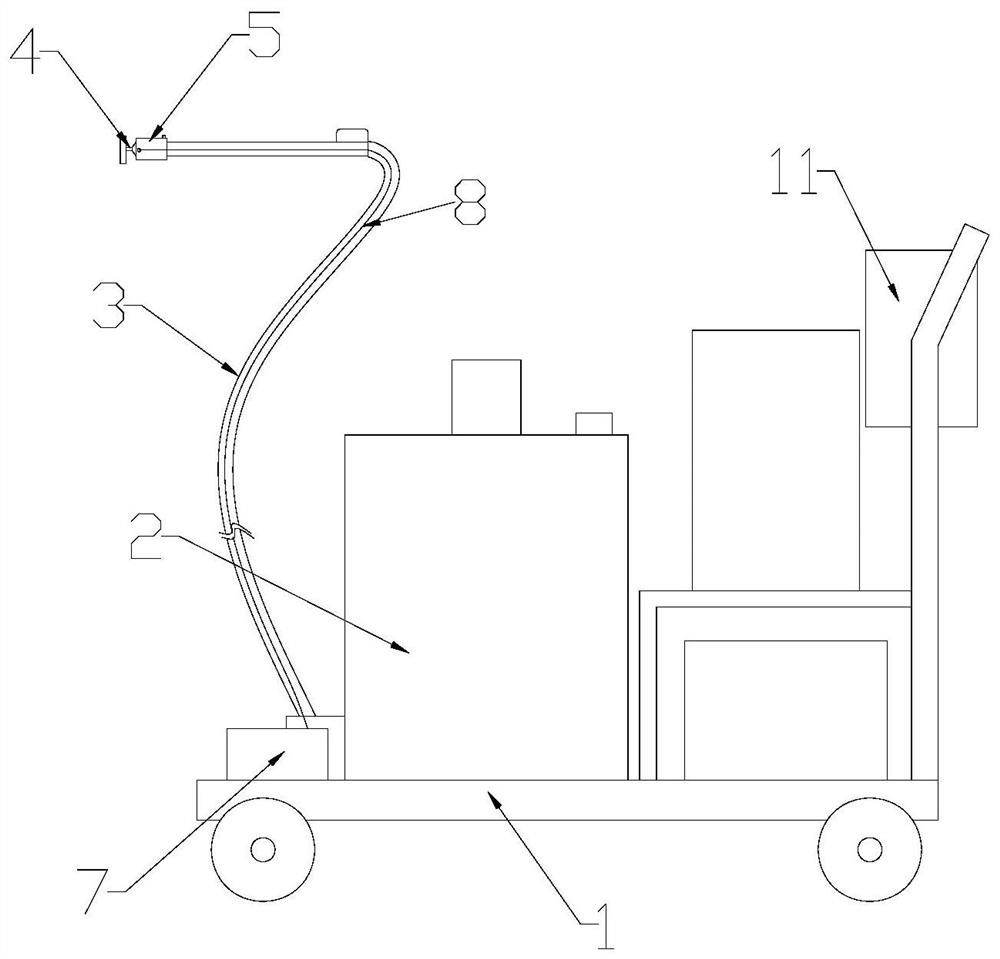

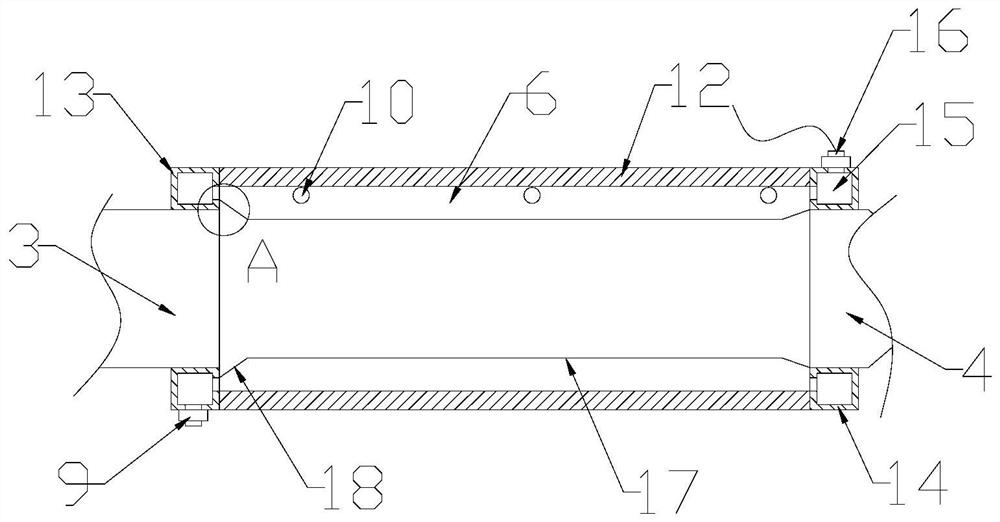

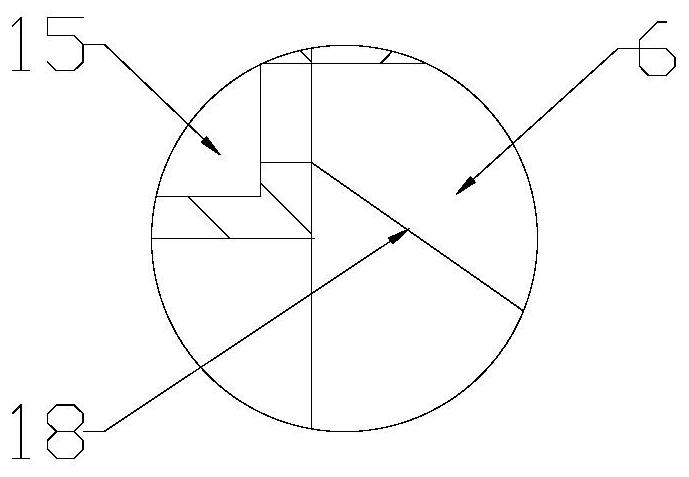

[0026] Such as Figure 1-3 As shown, an asphalt pavement filling device includes a vehicle frame 1 on which a hot-melt box 2 and a spray gun are fixed. The spray gun includes a delivery pipe 3 and a nozzle 4. One end of the delivery pipe 3 passes through a feed pump and a hot-melt box. The outlet of 2 is connected, and the other end is connected with the nozzle 4, and the connection assembly 5 with adjustable inner diameter is connected between the delivery pipe 3 and the nozzle 4. The tube 3 and the nozzle 4 communicate with each other through an elastic hose, and an inflatable chamber 6 is formed between the elastic hose and the outer pipe. An air pump 7 is also fixed on the frame 1, and the air pump 7 is connected to the inflatable chamber 6 through an air delivery pipe 8. An air outlet communicating with the inflatable cavity 6 is arranged on the pipe, a control valve 9 is installed at the air outlet, and the air delivery pipe 8 is fixed on the outside of the delivery pipe...

Embodiment 2

[0032] Adopt the using method of the asphalt pavement filling device described in embodiment 1, may further comprise the steps:

[0033] (1) According to the crack depth of the asphalt pavement, the air pump 7 inflates the air chamber 6 to adjust the inner diameter of the elastic hose. When the crack is deep, increase the amount of air in the air chamber 6 to reduce the inner diameter of the elastic hose , by reducing the inner diameter of the elastic hose, increase the discharge pressure of the nozzle 4; when the crack is shallow, reduce the amount of air inflated in the inflation chamber 6, so that the inner diameter of the elastic hose increases;

[0034] (2) The hot melt box 2 heats the potting glue to the required heat, the heated potting glue enters the elastic hose through the delivery pipe 3, and then enters the nozzle 4 through the elastic hose, and is sprayed out through the nozzle 4 to clean the cracks. Pouring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com