Fiber-based three-dimensional porous composite material for bone repair and preparation method thereof and molded product

A three-dimensional porous, composite material technology, used in medical science, tissue regeneration, prosthesis, etc., can solve the problems of lack of macroscopic three-dimensional structure, uneven distribution of internal fibers, and lack of mechanical support, achieving low cost and easy molding. , high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060] In the first embodiment of the present invention, a fiber-based three-dimensional porous composite material for bone repair is provided.

[0061] The composition of the fiber-based three-dimensional porous composite material includes micro-nano fiber powder and a binder, which are prepared by uniformly mixing the micro-nano fiber powder and the binder and undergoing a pore-forming process. in particular:

[0062]

[0063] The micro-nano fiber powder in the present invention means that the fiber raw material is pulverized and obtained with or without surface mineralization treatment.

[0064] The fiber raw material in the present invention can be various common fiber raw materials in this field. For example, it can be selected from synthetic polymer fibers, natural polymer fibers, and inorganic fibers, or a mixture of two or more fibers.

[0065] The synthetic polymer fibers of the present invention can be selected from artificially synthesized fibers that are degrad...

no. 2 approach

[0114] The second embodiment of the present invention provides a method for preparing a fiber-based three-dimensional porous composite material for bone repair. The method comprises the steps of:

[0115] Step 1: preparing fibers with a diameter of 0.1-100 μm by electrospinning, and then pulverizing the fibers by crushing technology to obtain micro-nano fiber powder with a particle size of 10-500 μm;

[0116] Step 2: the step of uniformly mixing the micronano fiber powder and the binder to obtain a mixed system;

[0117] Step 3: a step of subjecting the mixed system to a pore-forming process to obtain the fiber-based three-dimensional porous composite material;

[0118] The binder includes biodegradable and self-curable inorganic components; based on the total mass of the porous composite material, the content of the micro-nano fiber powder is 5-50% by mass.

[0119] Typically, the preparation method of the present invention can be carried out according to the following step...

no. 3 approach

[0134] In the third embodiment of the present invention, there is provided a molded product, which is the fiber-based three-dimensional porous composite material for bone repair according to the first embodiment or the fiber-based three-dimensional porous composite material for bone repair according to the second embodiment. Preparation method of fiber-based three-dimensional porous composite material for bone repair The obtained fiber-based three-dimensional porous composite material is obtained by molding.

[0135] The molded product of the present invention can typically be a medical biological repair material, more specifically, a human bone repair material.

[0136] Any desired product can be obtained through different molding processes. Furthermore, the third embodiment of the present invention provides a three-dimensional porous scaffold for human bone repair.

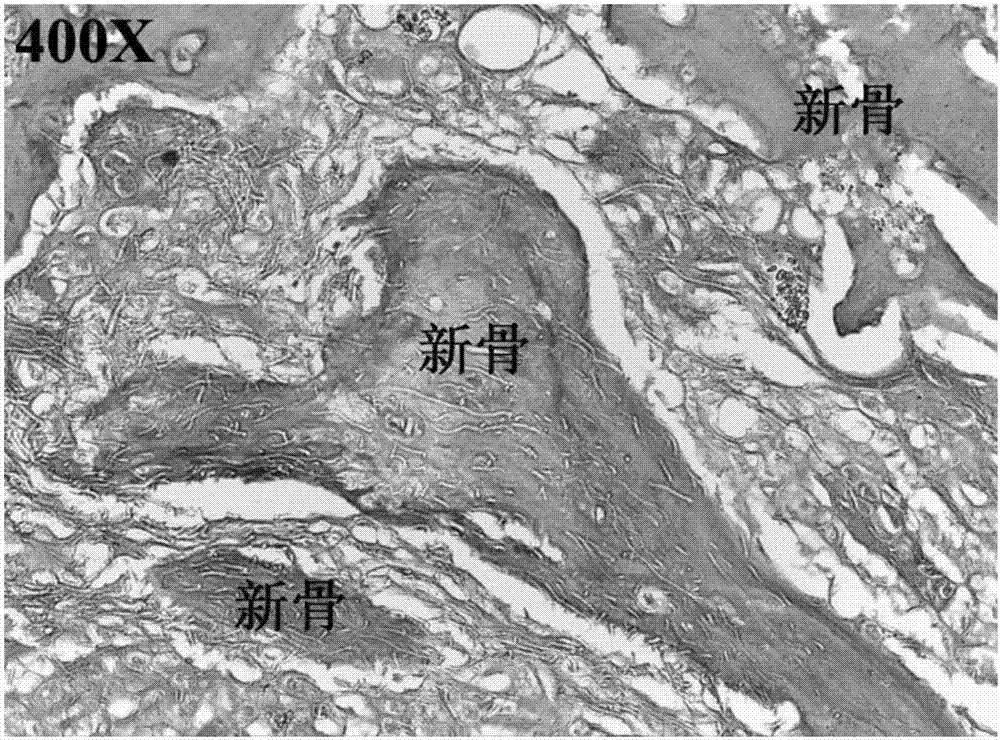

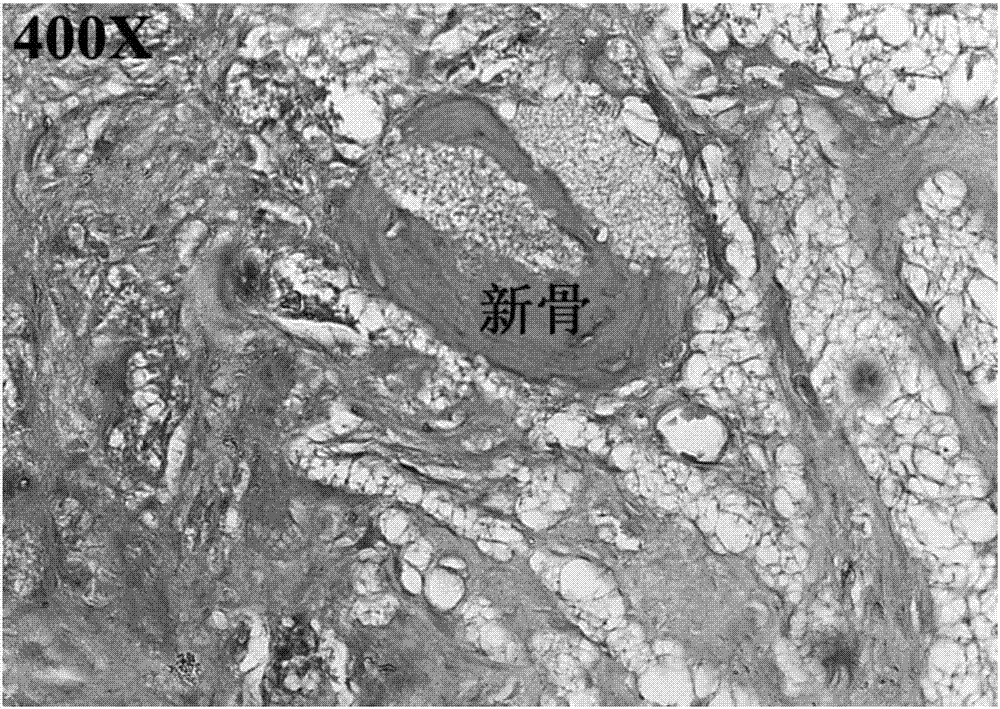

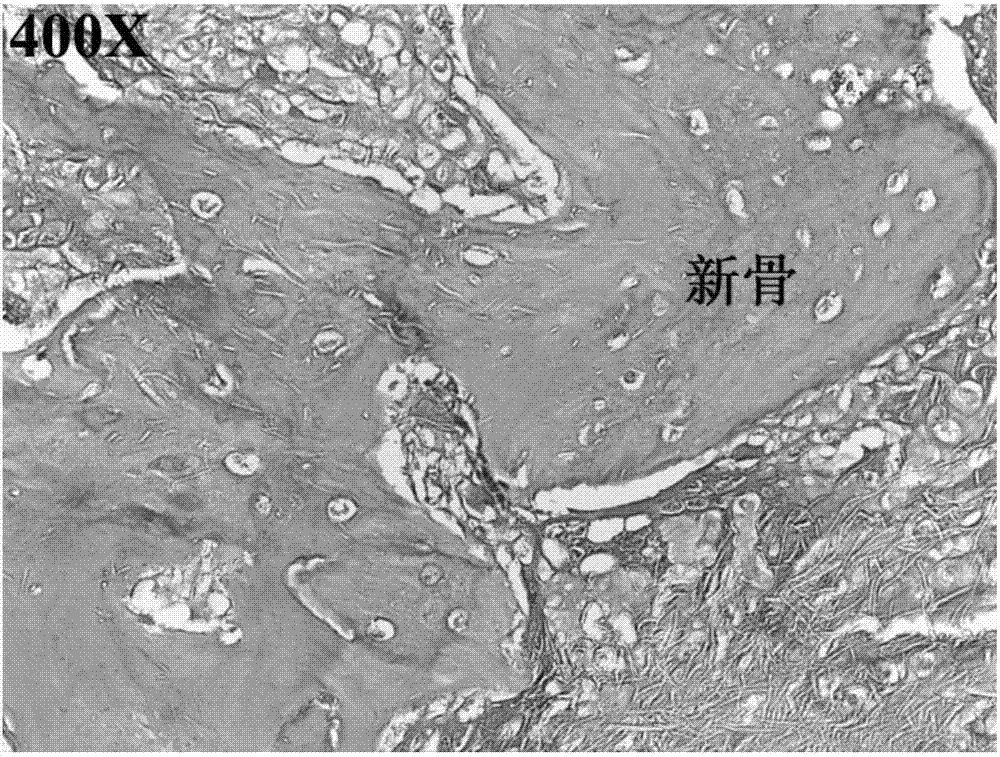

[0137] In such molded products, the presence of nanofibrous structure makes the scaffold have a significant e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com