Detachable and usable roadway filling retaining wall and construction method thereof

A technology for roadways and retaining walls, which is applied in the direction of filling, earthwork drilling, safety devices, etc., which can solve the problems of high labor intensity, one-time consumption of materials, and long construction period, etc., and achieves fast and convenient construction, simple structure, and high engineering volume. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

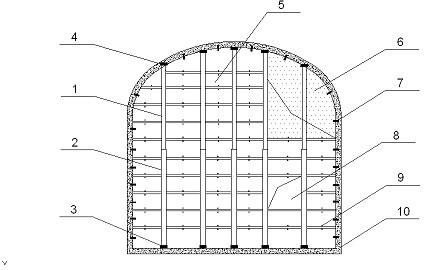

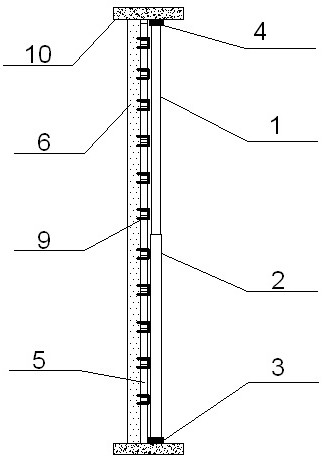

[0024] Refer to attached figure 1 , a roadway filling retaining wall that can be dismantled and utilized, including a single hydraulic prop, a bottom plate bearing plate 3, a roof plate bearing plate 4, a metal template 5, a filter cloth or a geotextile 6, and the single hydraulic prop includes a Together with the upper pillar 1 and the lower pillar 2, the single hydraulic pillars are arranged at certain intervals in the roadway, and the upper end of the upper pillar 1 and the lower end of the lower pillar 2 of the single hydraulic pillars are respectively fixed on the top plate pressure bearing plate 4 and the bottom plate pressure bearing On the plate 3, a metal template 5 is arranged between two adjacent single hydraulic props, and a filter cloth or a geotextile 6 is flatly laid on the metal template 5.

[0025] In this embodiment, as attached figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com