Liquid filling device and liquid filling system

A technology of liquid filling and liquid pressure, applied in liquid materials, packaging, transportation and packaging, etc., can solve the problems of low filling efficiency, inability to meet high-speed filling production, and inability to perform filling operations, and achieve filling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

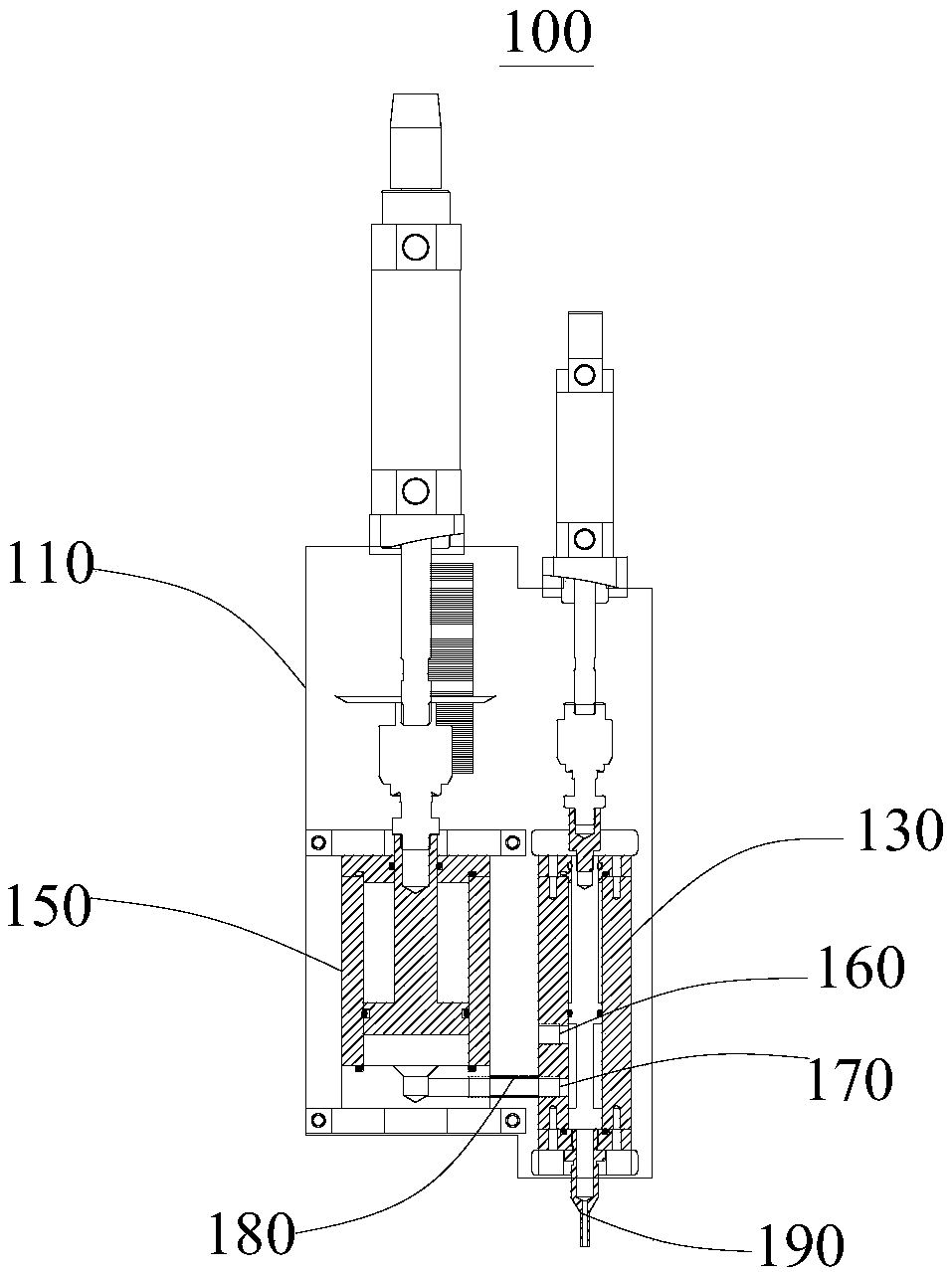

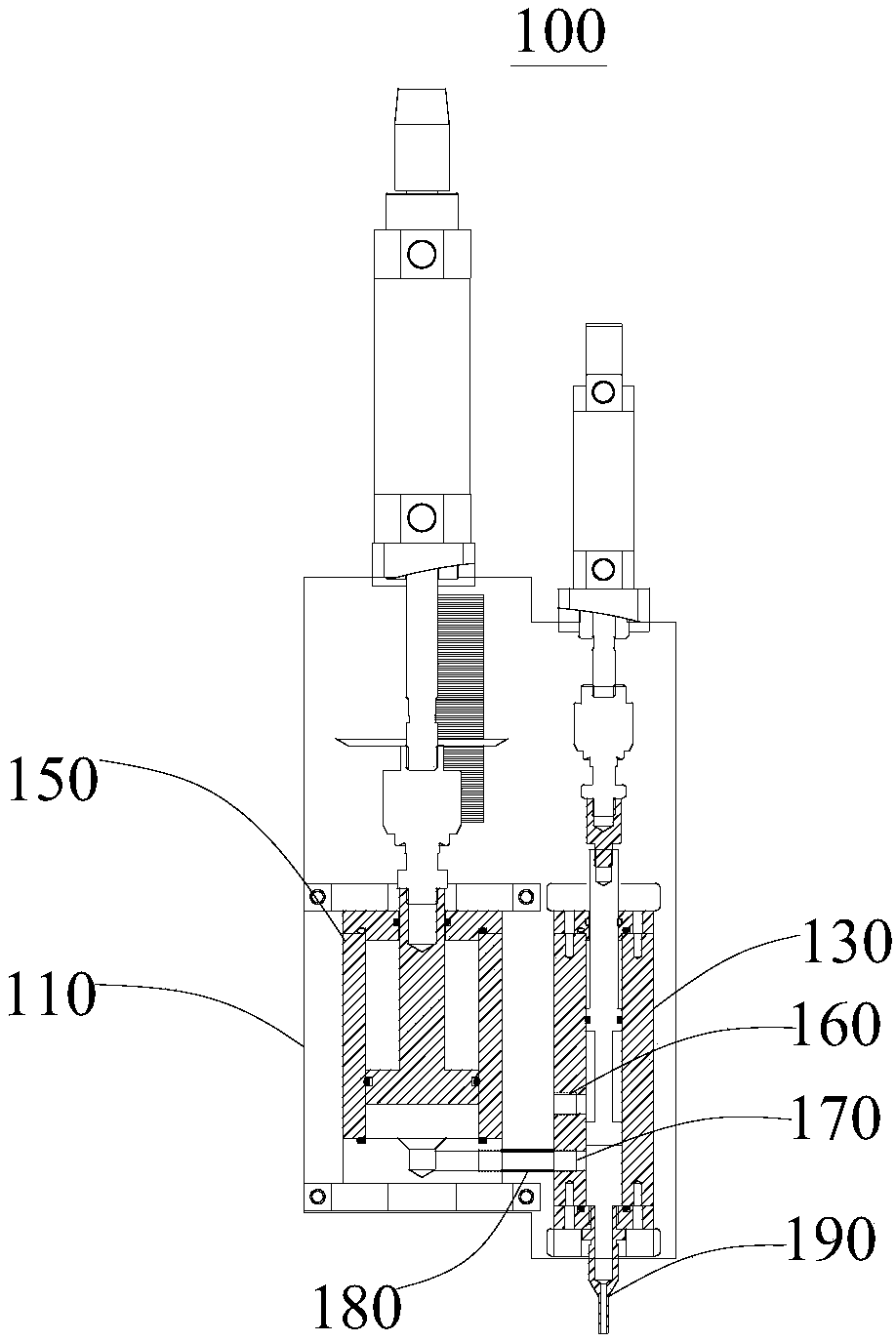

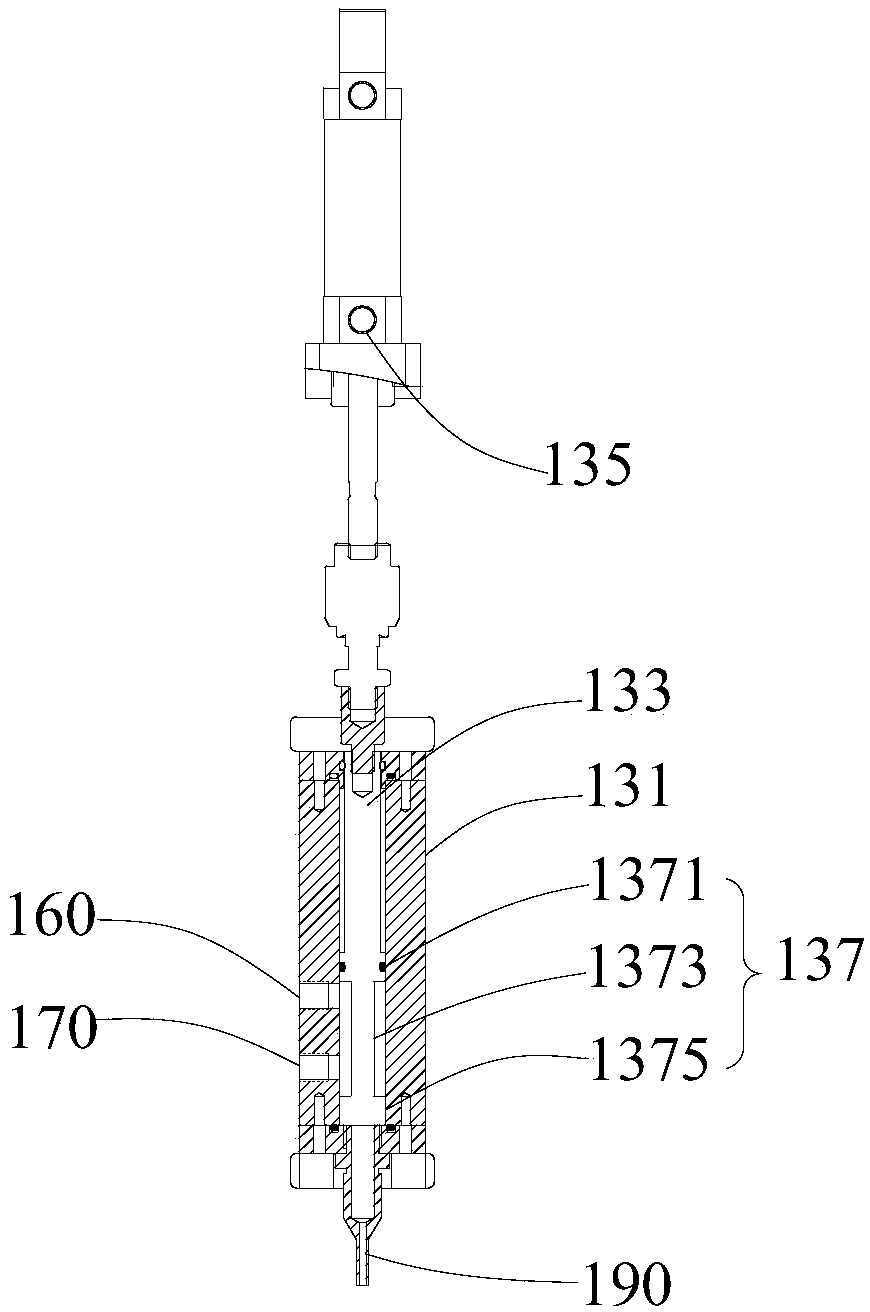

[0034] see in conjunction Figure 1 to Figure 4, the present embodiment provides a liquid perfusion device 100, including a cylinder fixed base plate 110, a first liquid injection cylinder 130 and a second liquid injection cylinder 150, the first liquid injection cylinder 130 and the second liquid injection cylinder 150 are both arranged on On the fixed base plate 110 of the cylinder body, a first interface 160 and a second interface 170 are opened on the first liquid injection cylinder 130, the first interface 160 is used to connect the liquid pressure barrel, the second interface 170 is provided with an external connection pipe 180, the first interface 160 is selectively communicated with the second interface 170, and the two ends of the external connection pipe 180 are respectively connected with the first liquid injection cylinder 130 and the second liquid injection cylinder 150, so that the inner cavity of the first liquid injection cylinder 130 and the second liquid injec...

no. 2 example

[0046] This embodiment provides a liquid perfusion system, including a liquid pressure tank (not shown in the figure) and a liquid perfusion device 100, wherein the basic structure and principle of the liquid perfusion device 100 and the technical effects produced are the same as those of the first embodiment, for brief For the description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0047] The liquid filling device 100 includes a cylinder body fixed base plate 110, a first liquid injection cylinder 130 and a second liquid injection cylinder 150, the first liquid injection cylinder 130 and the second liquid injection cylinder 150 are both arranged on the cylinder body fixed base plate 110, the second liquid injection cylinder 130 A liquid injection cylinder 130 is provided with a first port 160 and a second port 170, the second port 170 is provided with an external connection pipe 180, the first port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com