Adjustable filling valve

A filling valve, adjustable technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problem of filling work that cannot meet the high-precision requirements, it is difficult to meet the diverse requirements of small batches, and the scope of application of the filling valve is single, etc. problems, to achieve the effect of improving work precision and processing quality, simple structure and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

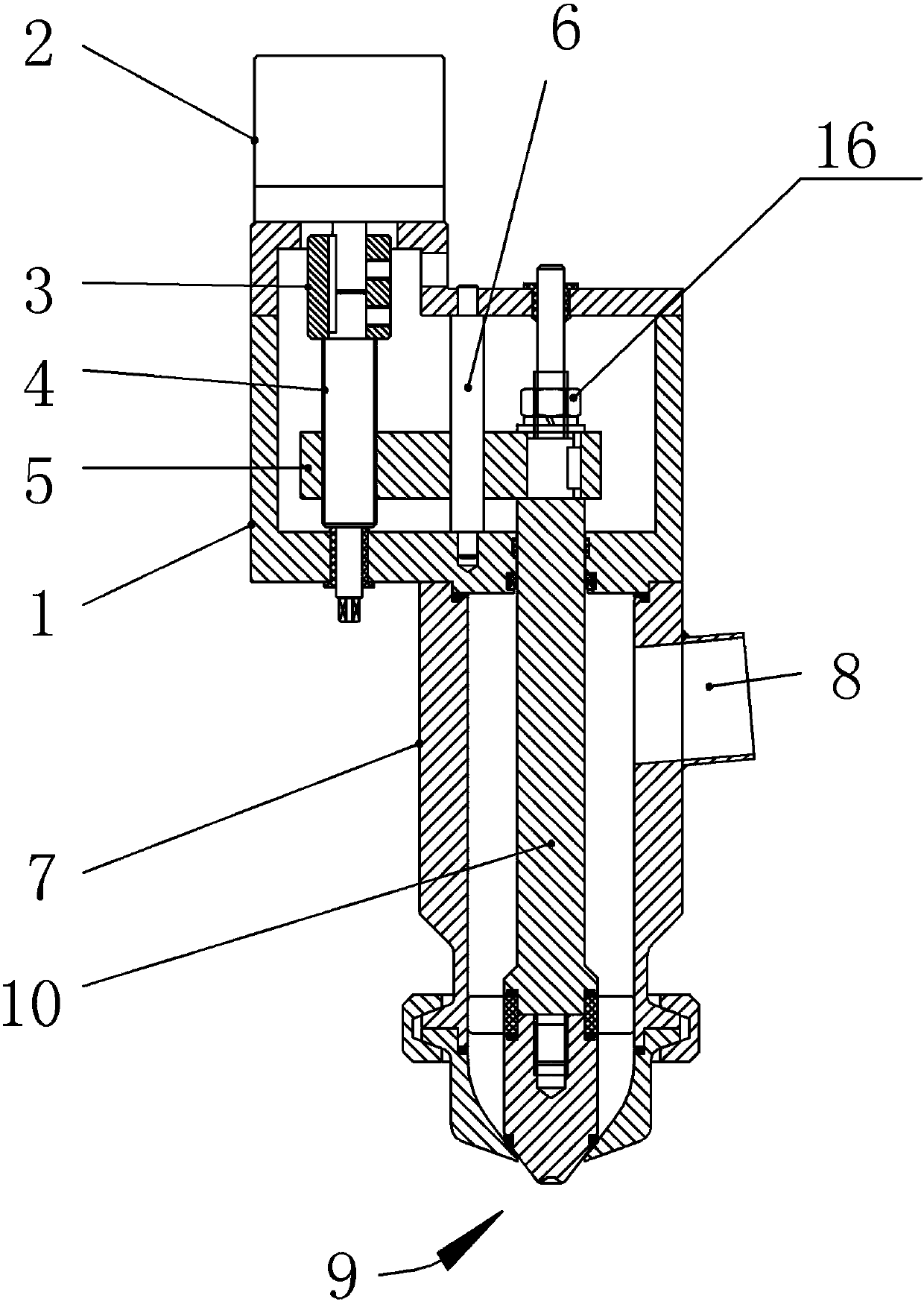

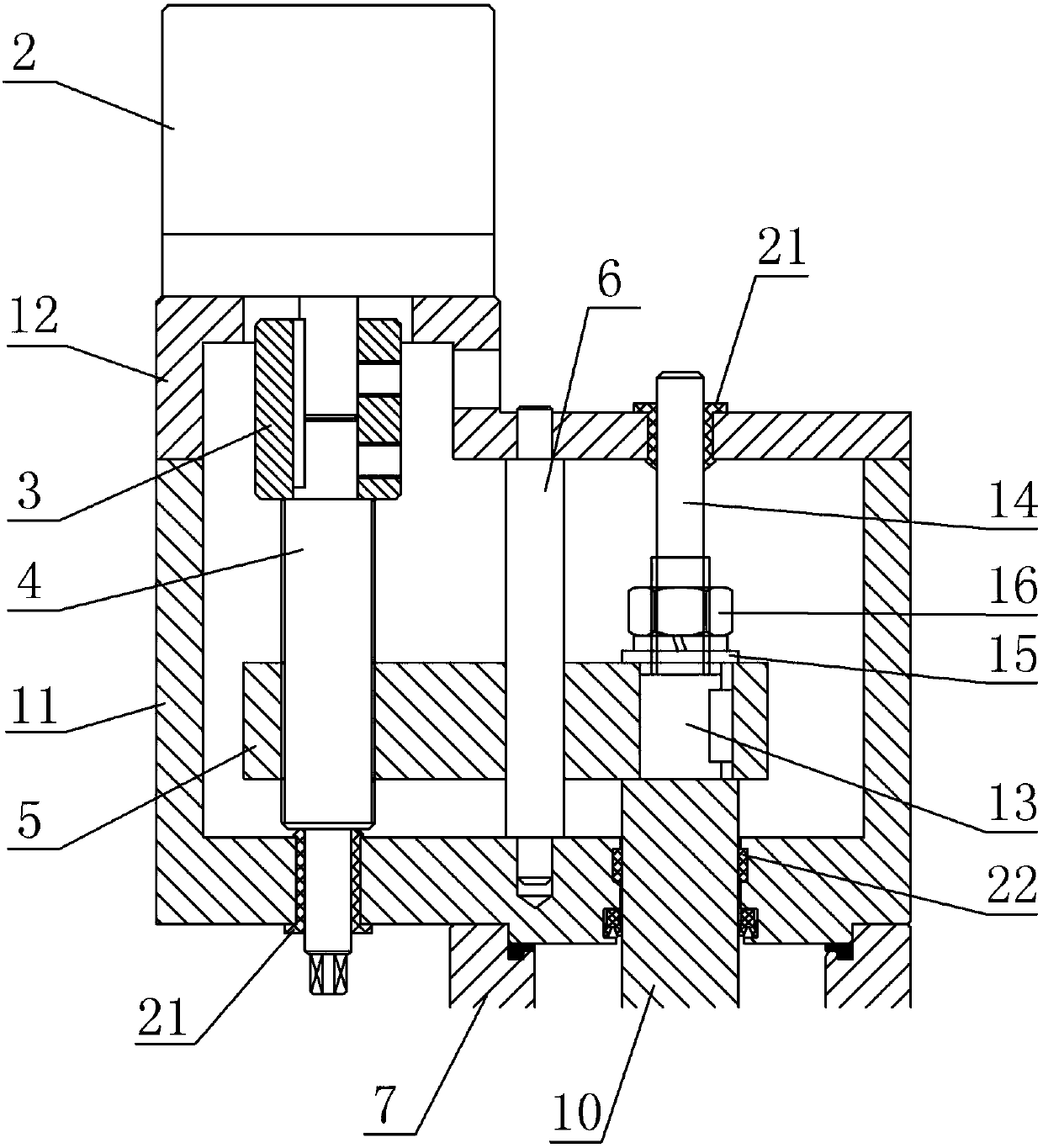

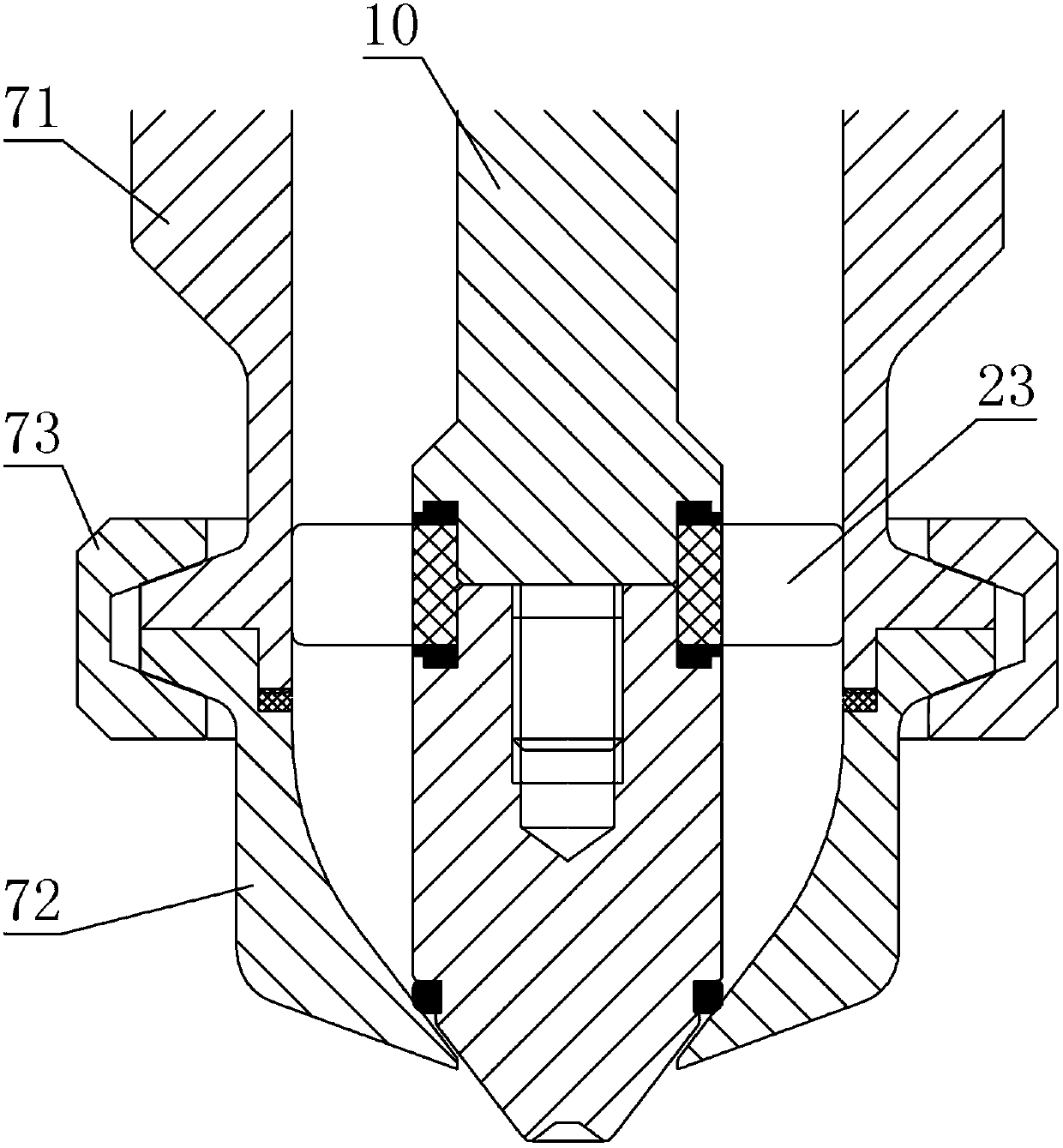

[0008] An adjustable filling valve, including a fixed seat 1 fixedly installed on the filling machine, a motor 2 is installed on the fixed seat, the output shaft of the motor is connected with a screw 4 through a coupling 3, and a sliding rod is also installed on the fixed seat 5. The axial direction of the sliding rod is parallel to the screw rod, and the two ends of the sliding rod are rotatably installed on the fixed seat, and there is another slider 6, which is set on the sliding rod and screwed with the screw rod; filling The end of the valve body 7 of the valve is fixedly installed on the fixed seat, and the end of the valve body is sealed with the fixed seat. The valve body is provided with a feed port 8 and a discharge port 9 for liquid circulation. The valve body is equipped with a valve The axial direction of the spool 10 is parallel to the screw rod, one end of the spool is movably closed or separated from the discharge port of the valve body, the other end of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com