Bone tissue repair material as well as preparation method and application thereof

A technology for repairing materials and bone tissue, which is applied in the field of bone tissue repairing materials and its preparation. It can solve the problems of high partial or complete shedding of mineralized silk protein particles, a single method for obtaining products, and large capacity. It achieves low requirements for reaction equipment, Avoid scattering or leaking, the effect of increased elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the bone tissue repair material provided by the present invention comprises the following steps:

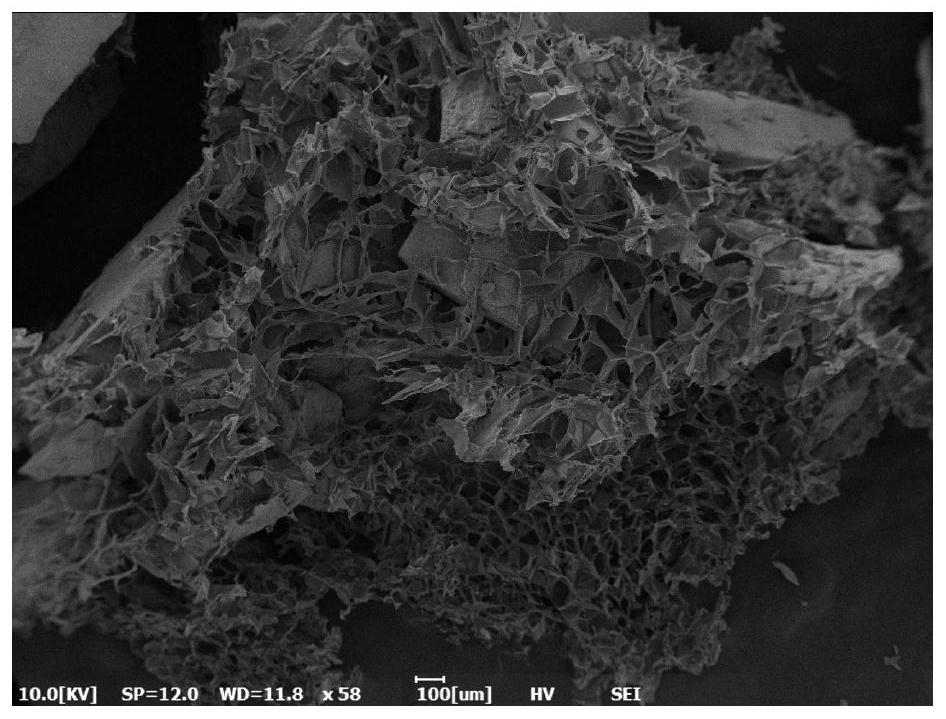

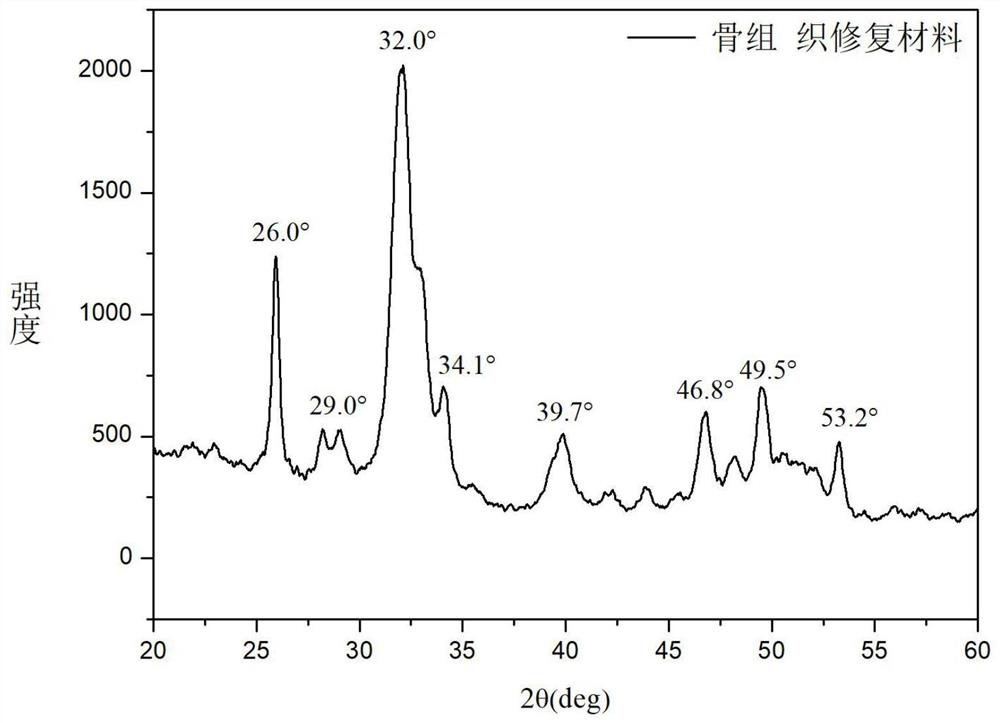

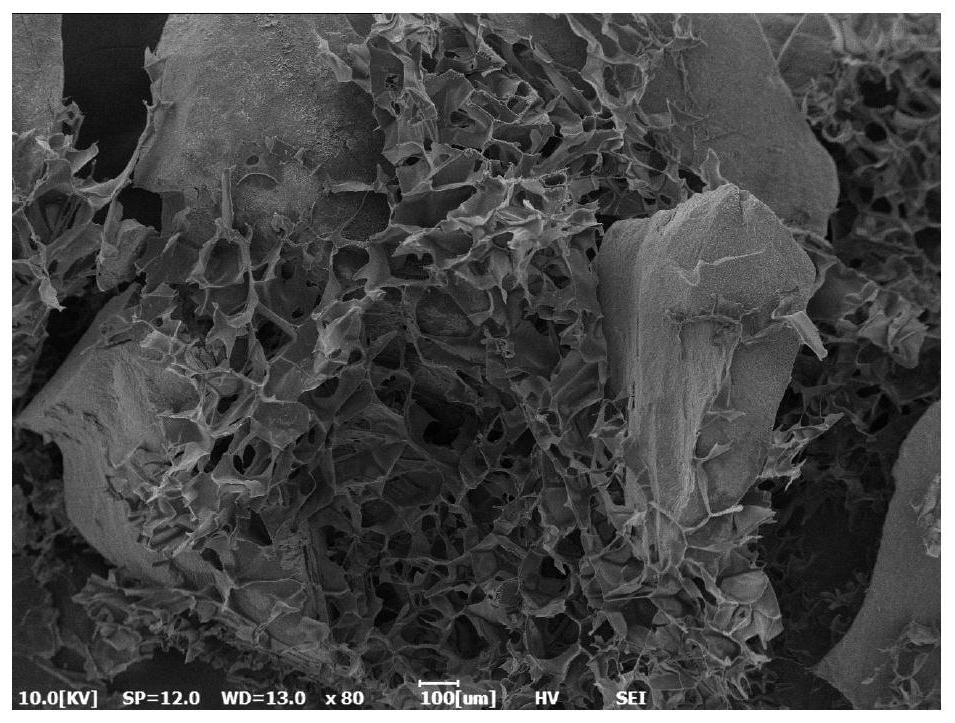

[0034] (1) In the liquid phase system of pH=10~12, the soluble calcium salt and soluble phosphate (or phosphoric acid) with the molar ratio of Ca and P of 5:3 undergo in situ co-precipitation reaction on the natural polymer A, and the precipitation reaction occurs. After cleaning, drying, grinding and sieving, the hydroxyapatite-natural polymer A nanocomposite particles of different specifications are formed;

[0035] (2) The hydroxyapatite-natural polymer A nanocomposite particles and the natural polymer B are uniformly mixed in a liquid phase system, then placed in a mold for vacuum freeze-drying, and then soaked and dried in absolute ethanol to obtain Bone tissue repair material with fixed morphology;

[0036] Among them, the natural polymer A and the natural polymer B are the same or different.

[0037] Specifically include the following ste...

Embodiment 1

[0049] (1) Weigh 75.3 g of soluble silk fibroin, put it into 3L of purified water at a constant temperature of 40°C, and dissolve for 10 minutes under stirring at 150-1500 rpm to obtain a silk fibroin solution.

[0050] (2) Weigh 342.1 g of trisodium phosphate dodecahydrate, put it into the silk fibroin solution obtained in step (1) at one time, stir at 150 to 1500 rpm until the solution is clear, put in 354.2 g of calcium nitrate tetrahydrate at one time, and continue to stir;

[0051] (3) after a large amount of milky white precipitation appears in the reaction system, add 1.5L of concentrated ammonia water (NH 3 The concentration is 25-28 wt%), ensure that the pH value of the system is about 11, and stir for 3 hours to make it fully react.

[0052] (4) After the completion of the reaction, the stirring was stopped, and the reaction product was aged for 20 hours at a constant temperature of 40°C in the reaction vessel.

[0053] (5) Pour out the aged reaction product.

[0...

Embodiment 2

[0062] (1) Weigh 60.5 g of soluble silk fibroin, put it into 3 L of purified water at a constant temperature of 37°C, and dissolve for 10 minutes under stirring at 1000 rpm to obtain a silk fibroin solution.

[0063] (2) put 342.1g potassium dihydrogen phosphate into the silk fibroin solution prepared in step (2) at one time, stir at a rotating speed of 500~1000rpm until the solution is clear, and then put 354.2g anhydrous calcium chloride into it at one time, Continue to stir the reaction.

[0064] (3) After a large amount of milky white precipitation appears in the reaction system, sodium hydroxide solution (concentration is 3M) is added in batches to ensure that the pH value of the system is about 11, and the stirring is continued for 3 hours to make it fully react.

[0065] (4) After the reaction is completed, the stirring is stopped, and the reaction product is aged for 16 hours under the constant temperature condition of 37°C in the reaction vessel.

[0066] (5) Pour ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com