Control method of food processor

A technology of a food processor and a control method, which is applied to timing control ignition mechanisms, utensils with integral electric heating devices, cooking utensils, etc., which can solve problems such as limitations, poor taste and quality of soybean milk, and poor product experience for users. Achieve the effect of reducing the risk of spillage and improving the taste of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

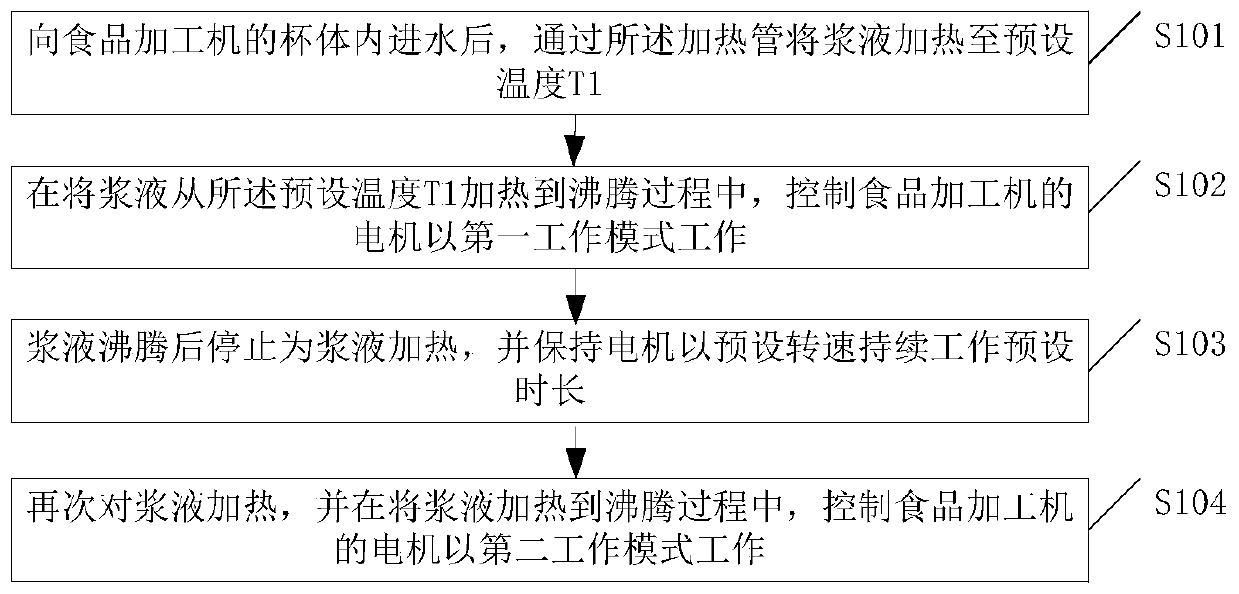

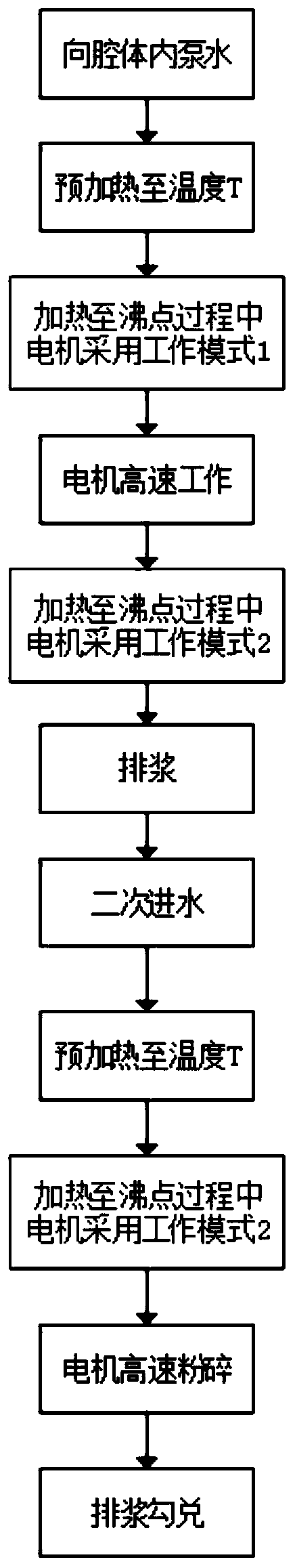

[0051] An embodiment of the present invention provides a method for controlling a food processor, the food processor includes a cup body and a heating device arranged on the cup body, and the heating device is used to heat the materials in the cup body; figure 1 As shown, the method may include S101-S104:

[0052] S101. After water is poured into the cup of the food processor, the slurry is heated to a preset temperature T1 by the heating device;

[0053] S102. During the process of heating the slurry from the preset temperature T1 to boiling, control the motor of the food processor to work in the first working mode;

[0054] S103, stop heating the slurry after the slurry boils, and keep the motor working at a preset speed for a preset time;

[0055] S104. Heating the slurry again, and controlling the motor of the food processor to work in the second working mode during the process of heating the slurry to boiling.

[0056] In an exemplary embodiment of the present invention...

Embodiment 2

[0068] On the basis of the first embodiment, this embodiment provides parameters for the preset temperature T1, the first working mode of the motor, and the second working mode of the motor.

[0069] In an exemplary embodiment of the present invention, the preset temperature T1 may satisfy: (Tf-3)°C≥T1≥(Tf-8)°C, where Tf is the boiling point temperature;

[0070] Speed M1 can meet: 5000rpm≥M1≥3000rpm;

[0071] Speed M2 can meet: 10000rpm≥M2≥8000rpm

[0072] Working hours N1 can meet: 4s≥N1≥2s;

[0073] Working hours N2 can meet: 8s≥N2≥4s;

[0074] The stop time W1 can satisfy: 8s≥W1≥4s;

[0075] The stop duration W2 can satisfy: 4s≥W2≥2s.

[0076] In an exemplary embodiment of the present invention, the preset temperature T1 is the preheating temperature point, which can satisfy (boiling point temperature Tf-3)°C≥T≥(boiling point temperature Tf-8)°C;

[0077] The first working mode: the rotational speed M1 can satisfy: 5000rpm≥M1≥3000rpm, the working length N1 can sat...

Embodiment 3

[0083] On the basis of the first or second embodiment, this embodiment provides an embodiment of adjusting the heating power as the temperature rises under different motor working modes during the heating process.

[0084] In an exemplary embodiment of the present invention, the method may further include: during the process of heating the slurry to boiling, in different working modes of the motor, adjusting the heating power as the temperature of the slurry increases.

[0085] In an exemplary embodiment of the present invention, the adjustment of the heating power may include:

[0086] When it is detected that the temperature of the slurry is lower than Tf-t1, the heating power adopts full power, 15°C≤t1≤25°C;

[0087] When it is detected that the temperature of the slurry is lower than Tf-t2, the heating power is half power, 8°C≤t2≤12°C;

[0088] When it is detected that the temperature of the slurry is lower than Tf-t3, the heating power shall be 1 / 3 full power, 4°C≤t3≤7°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com