Faucet pin combination structure

A combined structure and faucet technology, applied in the direction of valve shell structure, pipe/pipe joint/fitting, valve details, etc., can solve the problems of high production cost, high material cost, heavy metal exceeding the standard, etc., to reduce production cost and improve market competition The effect of energy saving and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

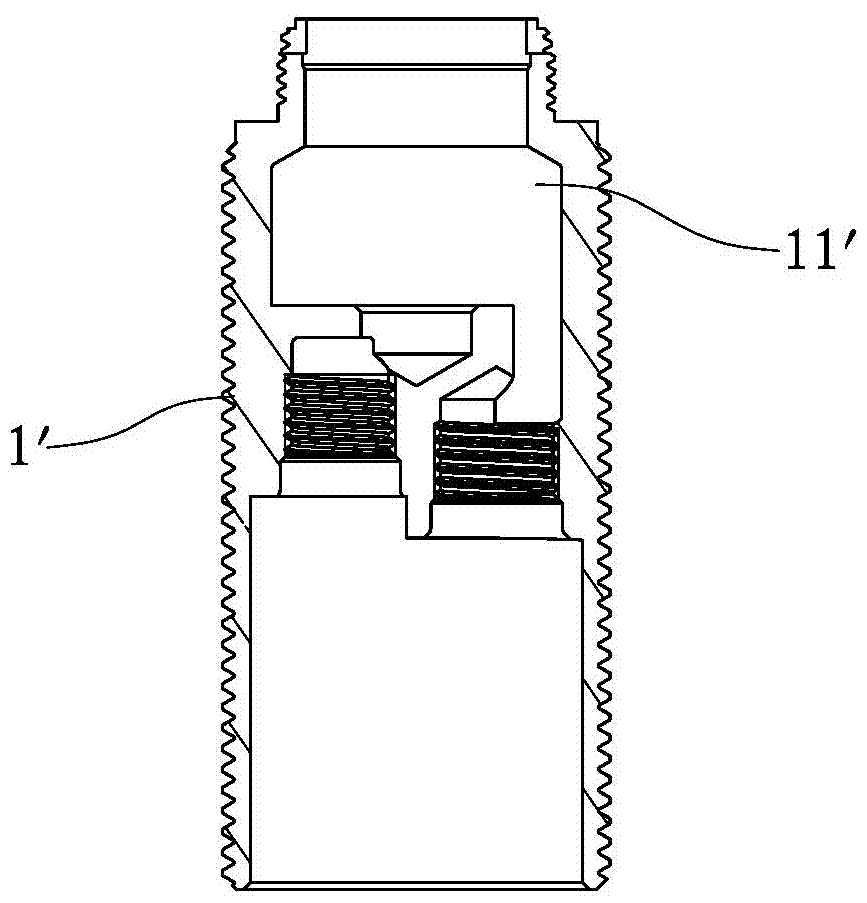

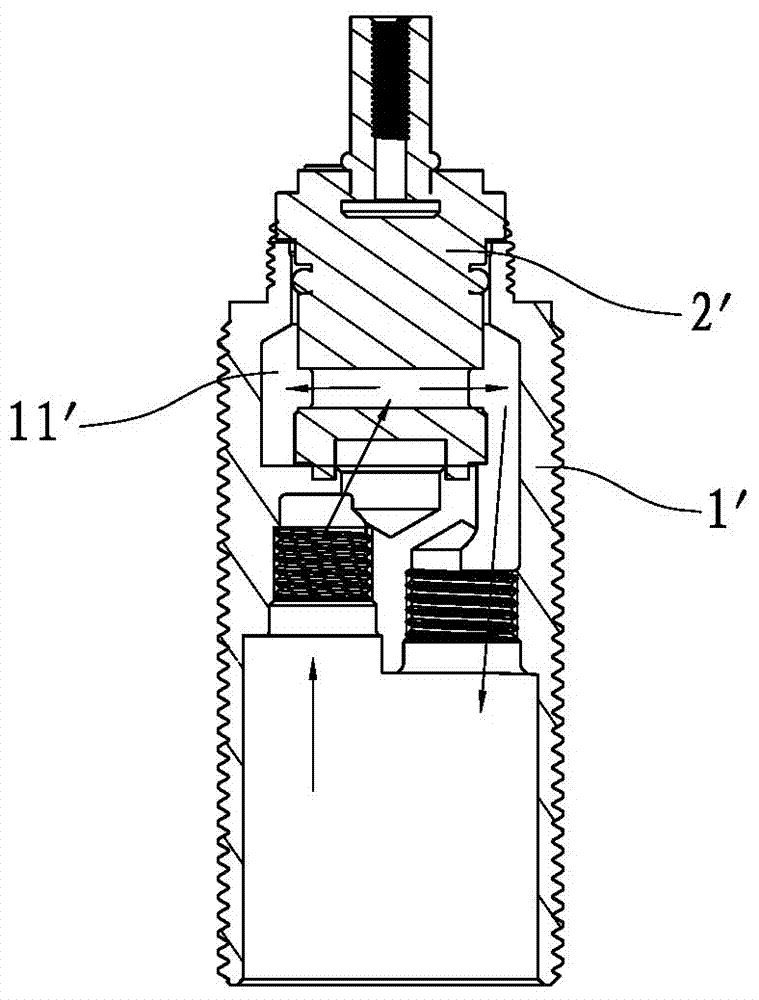

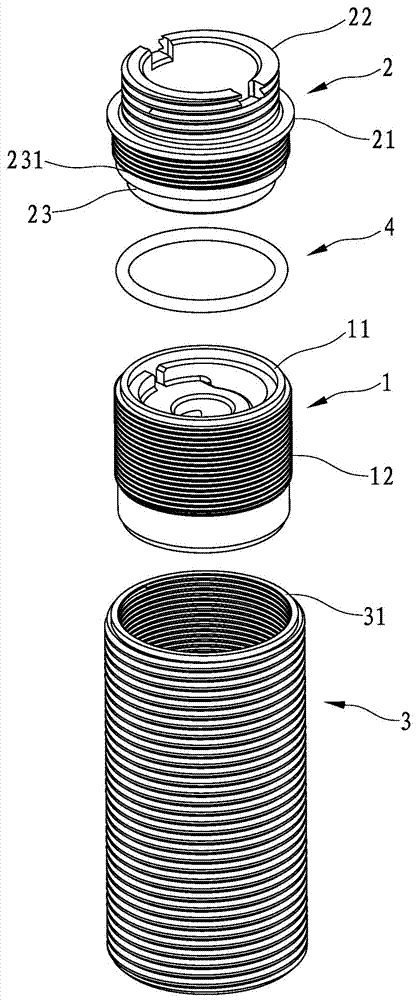

[0038] Such as Figure 3 to Figure 5F As shown, the present invention discloses a combination structure of faucet pins, in which an enlarged cavity 10 is formed to cooperate with the valve core; the key point is that the pins include an injection-molded tube body 1 and assembly 2, and Combined with the metal pipe sleeve 3 with external threads outside the tube base body 1, the tube base body 1 forms an opening 11 at the position where the pin matches the valve core's expansion cavity 10, so that the expansion cavity 10 can be smoothly penetrated. It is formed by injection molding; and the assembly 2 is molded exactly corresponding to the opening 11 of the tube base body 1, that is, when the assembly 2 is combined at the opening 11 of the tube base body 1, a complete enlarged cavity 10 is formed, and the assembly 2 cooperates to seal The part 4 is combined with the tube base body 1 in a sealed manner and is combined with the metal tube sleeve 3 at the same time.

[0039] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com