Die provided with PLC temperature control device and used for low-pressure pouring and method

A temperature control device and low-pressure technology, applied in the field of molds, can solve the problems of low efficiency, complex overall structure, and difficulty in ensuring the casting effect of the upper and lower molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

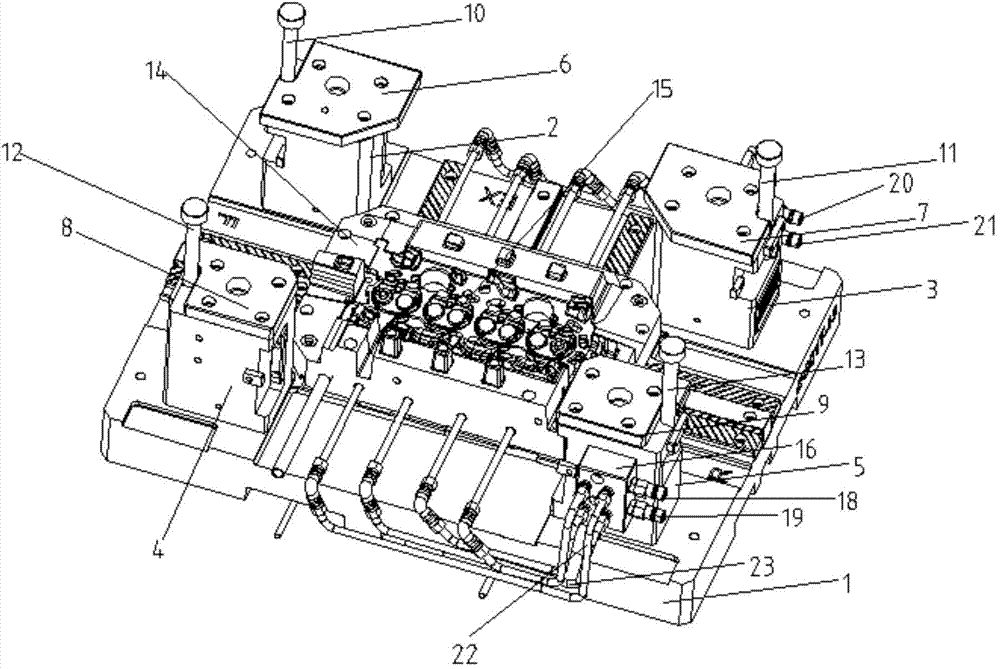

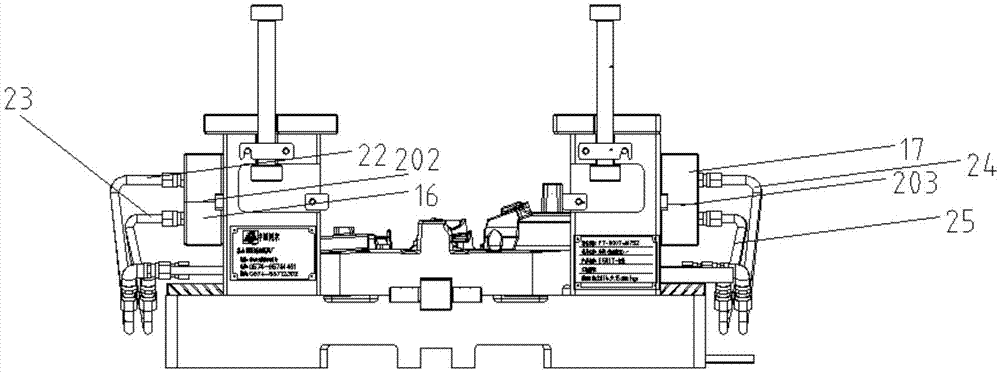

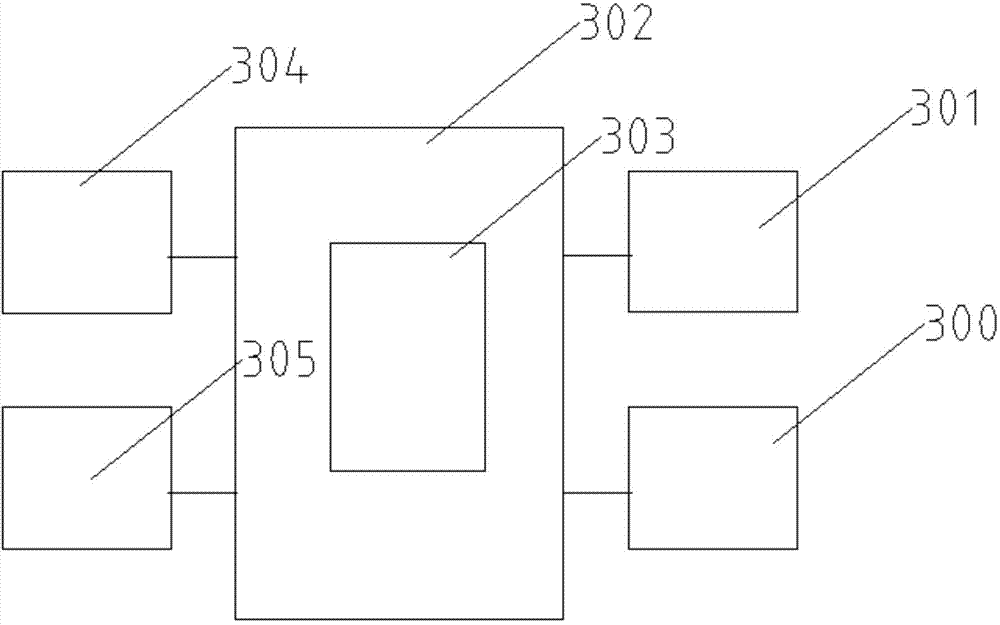

[0017] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0018] refer to figure 1 , figure 2 , image 3 As shown, the mold for low-pressure casting with a PLC temperature control device includes a base 1, the base 1 is a cuboid structure, and the upper left corner, upper right corner, lower left corner and lower right corner of the upper surface of the base 1 are The first column 2, the second column 3, the third column 4 and the fourth column 5 are respectively provided, the top of the first column 2, the top of the second column 3, the top of the third column 4 and the fourth column The top of 5 is respectively covered with the first backing plate 6, the second backing plate 7, the third backing plate 8 and the fourth backing plate 9, on the top of the first column 2, the top of the second column 3, the third The top of the column 4 and the top of the fourth column 5 are respectively provided with a vertically upward fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap