Double-opposite-direction inward-folded T-shaped groove core pulling mechanism of injection mold

A technology of core-pulling mechanism and injection mold, which is applied in the field of injection mold double-reverse retractable T-slot core-pulling mechanism, which can solve the problems of complex design and difficult structural design of the core-pulling mechanism on one side of the fixed mold, and achieve the goal of mechanism design. The effects of novelty, stable operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

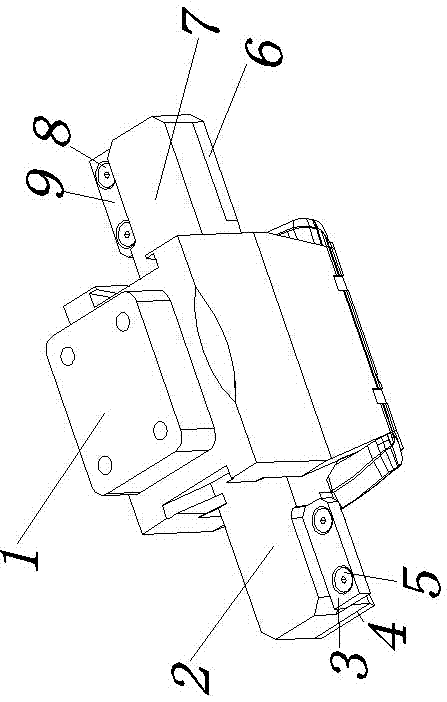

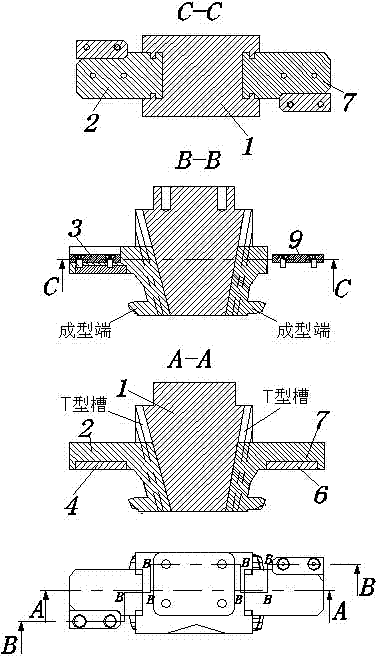

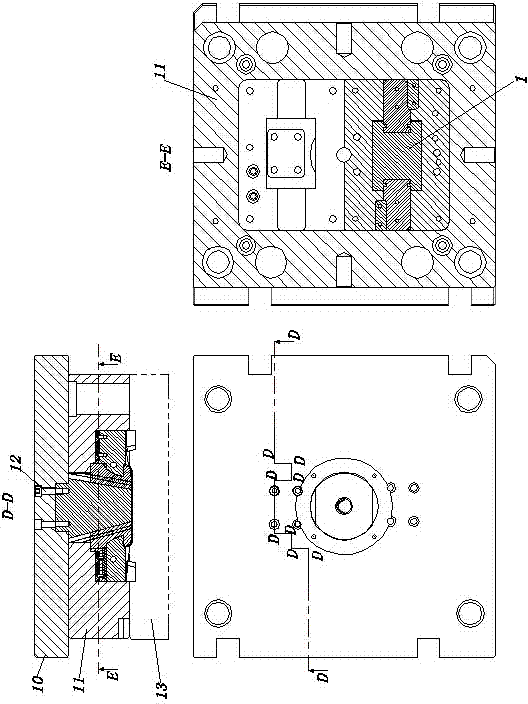

[0011] Figures 1-4 are explanatory diagrams of the structure and working principle of the present invention; figure 1 As shown, an injection mold double reverse inward T-slot core-pulling mechanism includes a central double T-slot wedge block 1, a first inner core-pulling slider body 2, a first bead 3, a first wear-resistant Plate 4, first bead screw 5, second wear-resistant plate 6, second inner core-pulling slider body 7, second bead screw 8, second bead 9;

[0012] Such as figure 2 As shown, the core-pulling power part of the core-pulling mechanism is a central double T-slot wedge block 1, and the central double T-slot wedge block 1 is installed on the fixed mold seat plate of the mold through screws; the first bead 3, the first The wear-resistant plate 4, the second wear-resistant plate 6, and the second bead 9 are installed on the mold cavity through screws; the first bead 3 guides the first inner core-pulling slider body 2, and the second bead 9 guides the second The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com