Constant current drive circuit with wire break detection

A technology of constant current drive and disconnection detection, applied in the direction of regulating electrical variables, instruments, control/regulating systems, etc., can solve the problems of difficult driving current control, long current lag time, complicated circuit design, etc., and achieve convenient driving current control. , The effect of disconnection detection is convenient and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

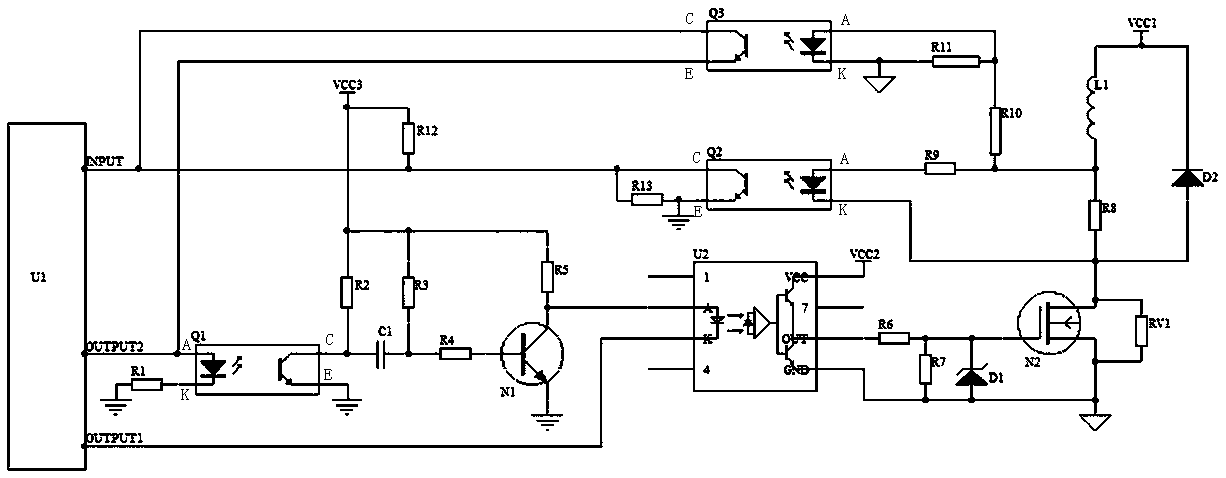

[0019] Such as figure 1 As shown, a constant current drive circuit for disconnection detection of the present invention includes a load L1, a sampling resistor R8, a sampling resistor R9, a sampling resistor R10, a freewheeling diode D2, a switch tube N2, an isolation chip U2, an isolation chip Q2, Isolate the chip Q3 and the control chip U1, one end of the load L1 is connected to the load power supply VCC1 and the cathode of the freewheeling diode D2, the other end of the load L1 is connected to one end of the sampling resistor R8, the sampling resistor R9 and the sampling resistor R10, and the sampling resistor R9 The other end is connected to the A pin of the isolation chip Q2, the other end of the sampling resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com