A reciprocating coal feeder driven by a linear motor

A technology of linear motors and coal feeders, applied in the field of electromechanical equipment and reciprocating coal feeders, can solve problems such as high failure rate, difficult maintenance, and large size, and achieve low failure rate, small maintenance workload, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] The application of a reciprocating coal feeder driven by a linear motor in the present invention is applied to a large vertical coal bunker. The feed port of the overall device is installed in parallel between the discharge port below the coal bunker and the belt conveyor, replacing the original one. reciprocating coal feeder.

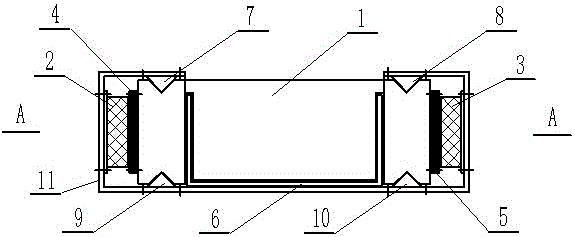

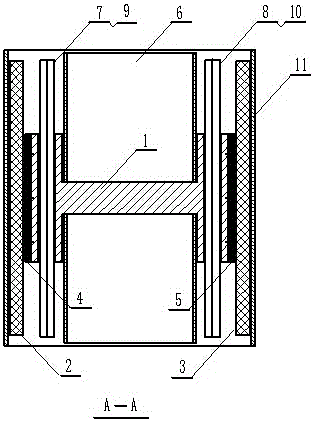

[0034] It consists of three parts: the discharge device, the drive device and the bracket (refer to the attached figure 1 And attached figure 2), the bracket 11 is welded into a cuboid with front and rear openings with thick steel plates, and the steel plate at the upper middle position of the bracket 11 is cut and removed, and its width matches the width of the discharge chute 6. At the upper steel plate on the left side of the bracket 11 Install the upper left guide rail 7 and the upper right guide rail 8 at the upper right steel plate, install the lower left guide rail 9 at the lower steel plate on the left side of the bracket 11, and insta...

Embodiment approach 2

[0041] The application of a reciprocating coal feeder driven by a linear motor in the present invention is used to regulate the coal flow in a large vertical coal bunker. The feed port of the overall device faces upwards and is installed in parallel between the discharge port below the coal bunker and the belt conveyor. , to replace the original reciprocating coal feeder. At the same time, the three-phase AC power supply supplies power to the coils of the primary 2 of the left linear motor and the primary 3 of the right linear motor through the three-phase AC frequency regulator, changing the frequency of the three-phase AC power, thereby changing the moving speed of the discharge slider 1, and achieving the adjustment of fuel consumption. Purpose of coal flow. Others are the same as Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap