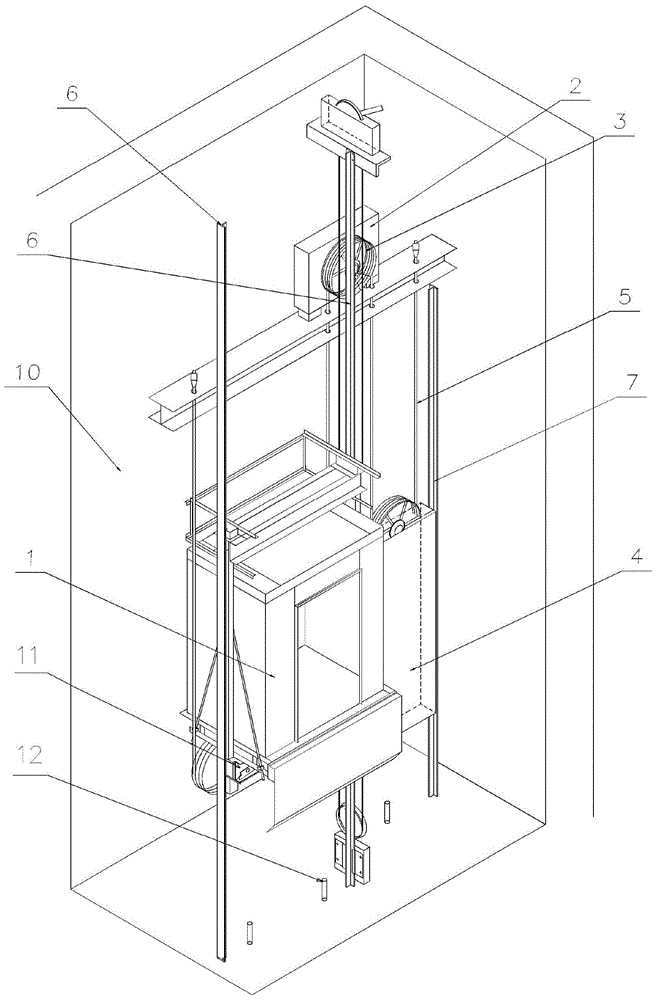

Elevator stop device with trigger mechanism

A trigger mechanism and elevator system technology, applied in the field of elevator accessories, can solve the problems that the well cannot meet the requirements of the escape space of the operators in the well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

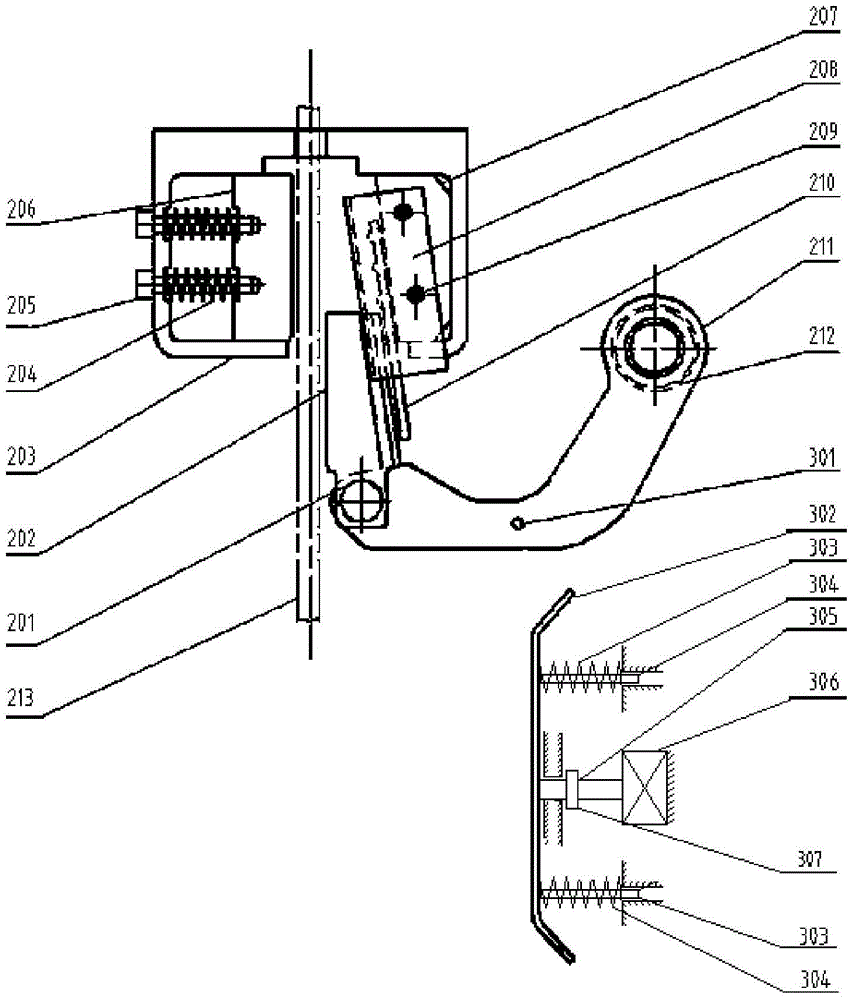

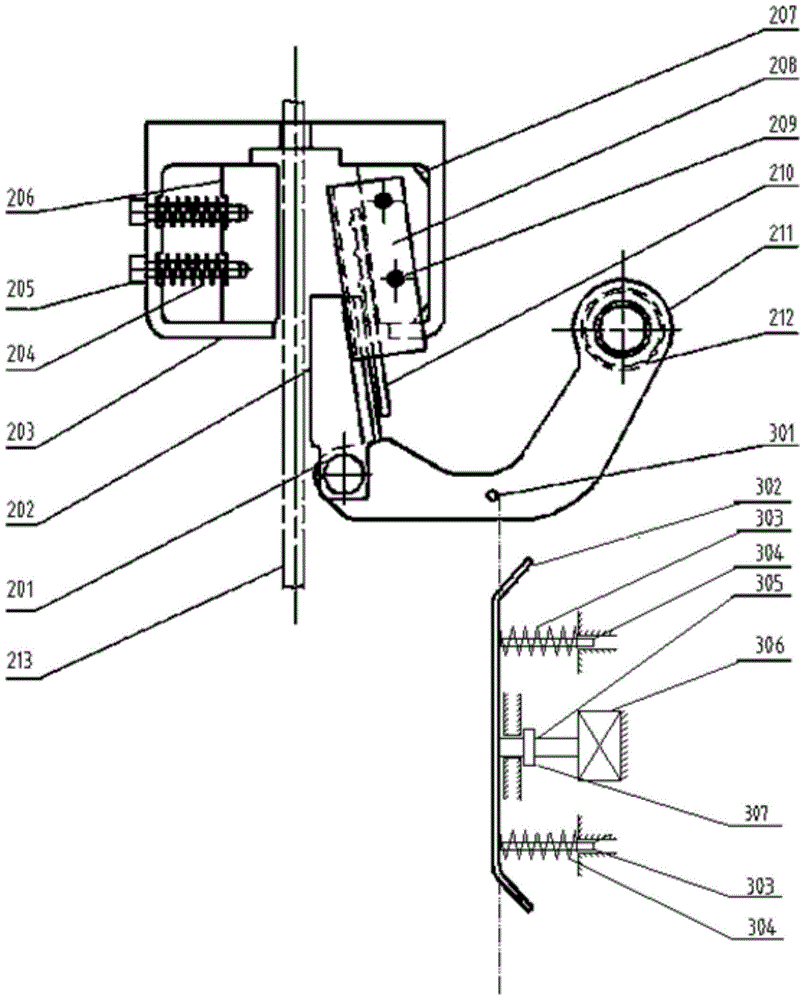

[0043] The preferred implementation of the present invention is a one-way mechanism similar to the safety gear of an elevator; taking the car (or counterweight) down-moving braking device as an example, when the elevator car (or counterweight) goes down, the braking mechanism acts It can produce a force that hinders the elevator car (or counterweight) from going down. When the elevator car (or counterweight) goes up, the force of the braking mechanism will decrease or disappear; because the elevator car (or counterweight) has already In the abnormal position of the overriding inspection operation, the maintenance personnel must first move the car (or counterweight) up to the normal position in the process of restoring the use of the elevator. If the force on the brake mechanism still exists, the up operation will become difficult; therefore, the braking mechanism should preferably act in one direction, as long as the car (or counterweight) can be stopped at a certain decelerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com