Two-layer suspension ceiling structure of integrated suspension ceiling and installation method thereof

A technology of integrated suspended ceiling and suspended ceiling, which is applied in the direction of ceiling, building components, building structure, etc., can solve the problems of long debugging time, many working hours, and difficult installation, so as to reduce the difficulty factor of installation operation, simplify the installation structure, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

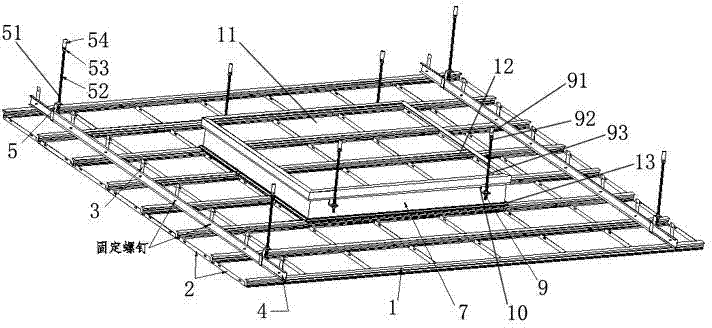

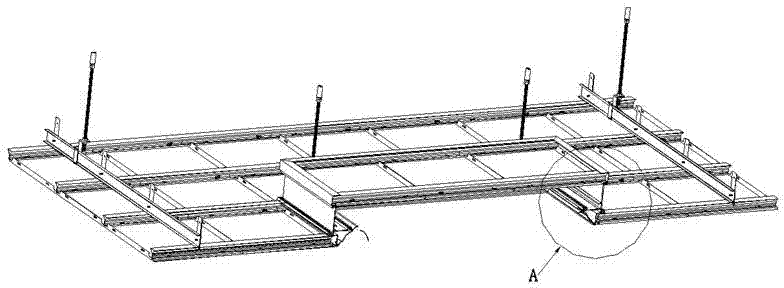

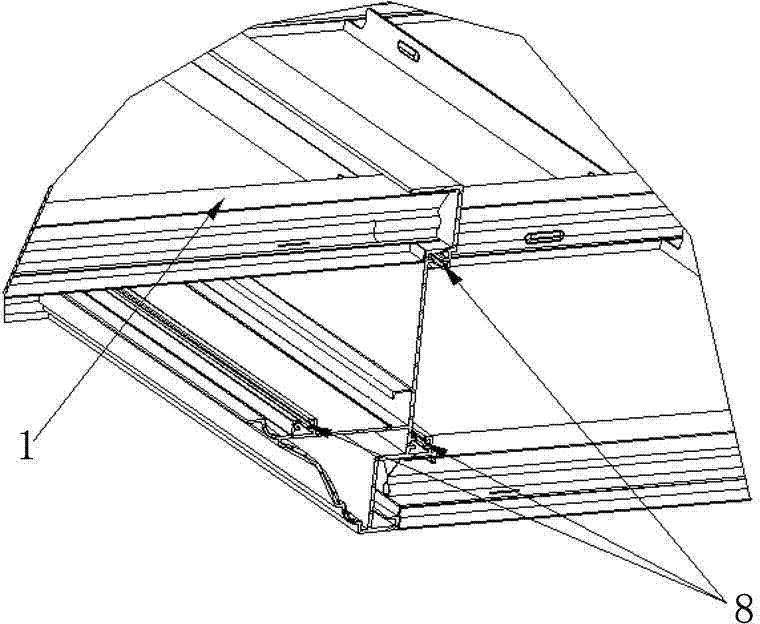

[0022] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-4 As shown, the two-story ceiling structure of an integrated ceiling in the present invention, the integrated ceiling is mainly composed of a triangular keel 1 and a plane gusset 2 buckled on the triangular keel 1, and the triangular keel 1 is connected by Part 3 is fixedly installed on the main keel 4 arranged transversely relative to the triangular keel, and the main keel 4 is fixed on the ceiling 6 of the roof through the suspender assembly 5. The two-story suspended ceiling structure mainly includes one by four two-story The top aluminum profile 7 is a two-layer ceiling frame formed by special corner codes 8 and screws, and the whole of the two-layer ceiling frame is fixedly installed on the ceiling 6 of the roof through the combined screw hanger 9; the two-layer top aluminum The upper part of the profile is provided with a transversely inner 90-degree U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com