An upright fiber cotton rimless mold cup, a forming method of the mold cup, and a split type rimless bra

A molding method and technology without rims, which can be applied to corsets, clothing, underwear, etc., can solve the problems of film being easily deformed by force, easy to move, and adverse effects, so as to improve wearing comfort, improve comfort, increase The effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

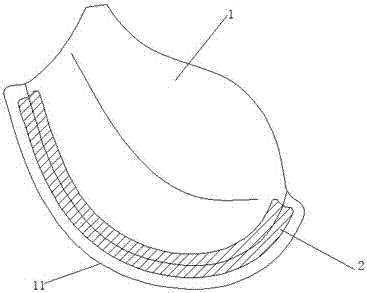

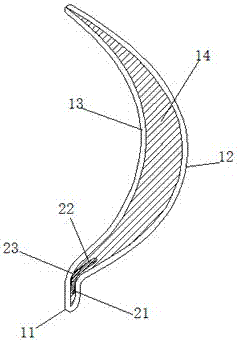

[0045] This embodiment provides a kind of upright fiber cotton mold cup without rims, such as figure 1 , including a mold cup body 1 and a 3D support 2 arranged at the bottom of the mold cup body. Such as figure 2 , the 3D support includes a longitudinally arranged reinforcing surface 21 and a concave supporting curved surface 22 formed by extending forward from the top of the reinforcing surface. The reinforcing surface and the supporting curved surface are connected by a smooth intermediate curved surface 23 .

[0046] The included angle between the reinforcing surface 21 and the lateral projection of the supporting curved surface 22 is 120°.

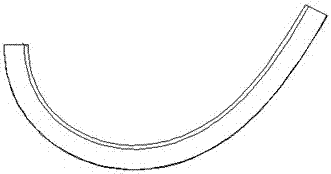

[0047] Such as image 3 , the forward projection of the supporting curved surface is a smooth concave curve, and the curvature of the curve increases from the outside of the mold cup to the inside of the mold cup. In addition, the forward projection of the supporting surface can also be set as an arc, and the 3D support can be ti...

Embodiment 2

[0063] This embodiment provides a molding method of the mold cup in Embodiment 1.

[0064] Including the following procedures:

[0065] a. Cut the sandwich fabric layer on the surface to a suitable size, and cut the inner layer and the upright cotton fiber layer to a suitable size; select a thermoplastic sheet and cut it into a strip whose curvature gradually increases from one end to the other ;

[0066] b. the sandwich fabric layer of the surface layer is put into a surface layer mould, and it is preheated and pressed;

[0067] c. covering the surfaces of the surface layer and the inner layer with thermal adhesive respectively;

[0068] d. enter the inner layer, the upright fiber cotton layer, the strip sheet, and the surface layer into a mold cup mold successively and position them;

[0069] e. hot pressing each raw material in the mold cup mold to obtain a rough mold cup;

[0070] d. Place the rough mold cup in a cold press mold cup mold for cold pressing;

[0071] e....

Embodiment 3

[0078] This embodiment provides a molding method of the mold cup in Embodiment 1.

[0079] Including the following procedures:

[0080] a. Cut the sandwich fabric layer on the surface to a suitable size, and cut the inner layer and the upright cotton fiber layer to a suitable size; select a thermoplastic sheet, and cut it into a strip whose curvature gradually increases from one end to the other ;

[0081] b. the sandwich fabric layer of the surface layer is put into a surface layer mould, and it is preheated and pressed;

[0082] c. covering the surfaces of the surface layer and the inner layer with thermal adhesive respectively;

[0083] d. Put the inner layer, the upright fiber cotton layer, the strip sheet and the surface layer into a cup mold successively and position them;

[0084] e. hot pressing each raw material in the mold cup mold to obtain a rough mold cup;

[0085] d. Place the rough mold cup in a cold press mold cup mold for cold pressing;

[0086] e. Cut of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com