Automatic rotating disc type cocoon cutting machine

A turntable, cocoon cutting technology, applied in metal processing and other directions, can solve the problems of silkworm cocoon cutting, manual operation and low efficiency for separation, and achieve the effect of high cocoon cutting efficiency, high success rate, and efficient automatic separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

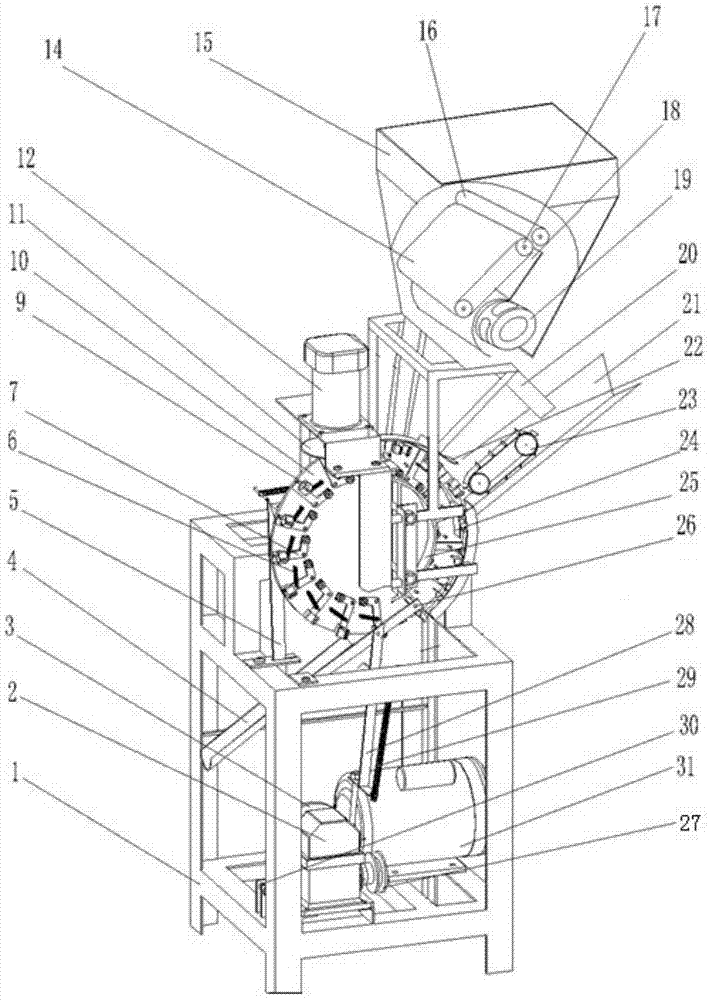

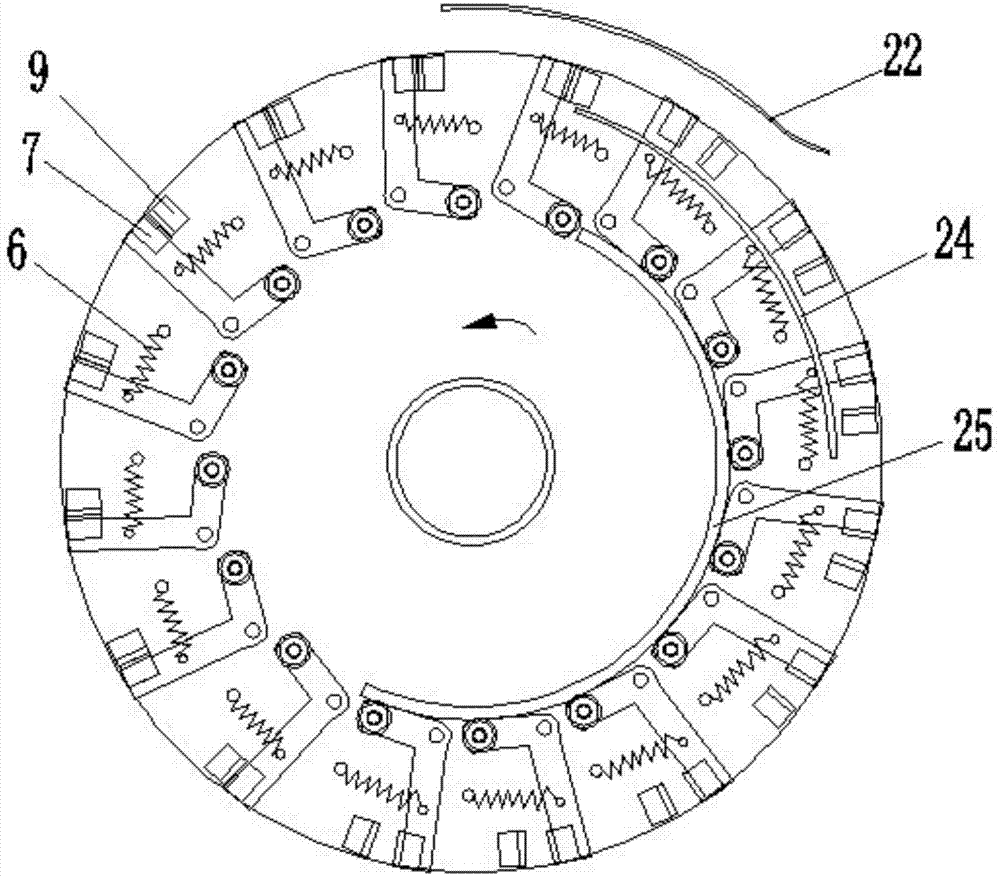

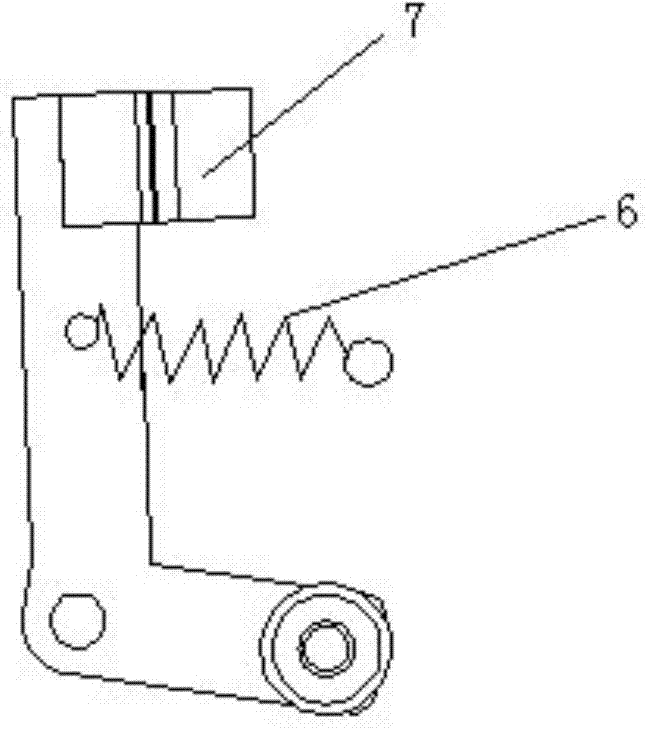

[0021] The present invention as figure 1 Shown, comprise hopper 15, be provided with the cocoon stripping belt 14 that is used to carry silkworm cocoon in the hopper 15, cocoon stripping belt 14 is attached on the driving roller shaft 17, and driven roller shaft 16 is pressed on the driving roller shaft 17 tightly, and the roller shaft two There is a bearing at the end and is connected with the hopper 15 through the bearing seat. A separation drum 19 is arranged under the driving roller shaft 17. When the driving roller shaft 17 rotates, it drives the cocoon stripping belt 14 to move, and drives the driven roller shaft 16 to reverse, and the cocoon stripping The cocoon outer layer cocoon clothing on the belt 14 is squeezed between the driven roller shaft 16 and the driving roller shaft 17, and at this moment the cocoon clothing is peeled off from the cocoon surface, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com