Method and device for sorting tobacco leaves through air blowing

A sorting device and tobacco leaf technology, applied in the field of machinery, can solve the problems of low work efficiency, high labor intensity, labor-intensive, etc., and achieve the effect of reducing labor intensity, low cost, and ideal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

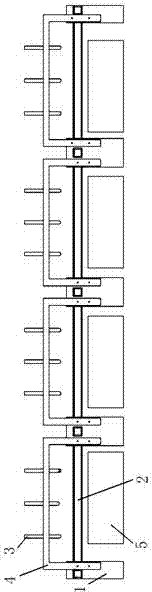

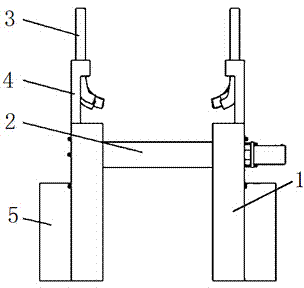

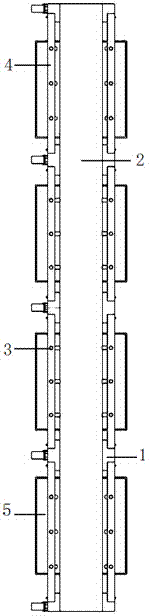

[0012] Embodiment of the present invention: use the method of sorting tobacco leaves by air blowing, set an air blowing pipe above the conveyor belt, and use the conveyor belt to transport the graded tobacco leaves. The blown air blows the tobacco leaves on the conveyor belt down to the tobacco leaf collection boxes on both sides of the conveyor belt to realize automatic tobacco leaf grading and sorting to improve the sorting efficiency of tobacco leaves.

[0013] The tobacco leaf sorting device includes a support 1 provided with a conveyor belt 2, four sets of air blowing pipes 3 connected to the air pump are arranged above the conveyor belt 2, and the same group of air blowing pipes 3 is divided into two rows on the left and right, symmetrically arranged on the conveyor belt 2 Both sides, the air blow pipe 3 on the left or right side are 3, and the vertical distance between the bottom of each air blow pipe 3 and the top surface of the conveyor belt 2 is 10cm; The other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com