Crankshaft Structure for Reducing Oil Circulation Rate of Rolling Rotor Compressor

A rolling rotor type, compressor oil technology, applied to crankshafts, rotary piston type/oscillating piston type pump components, machines/engines, etc., can solve system matching performance degradation, reduce system heat exchange capacity, refrigeration/heating The capacity does not increase accordingly, to achieve the effect of improving the system matching capacity, reducing the oil circulation rate, and ensuring the cooling/heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

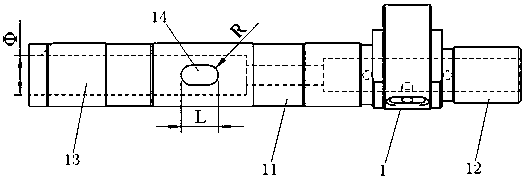

[0012] like figure 1 As shown, the crankshaft structure of the present invention that reduces the oil circulation rate of the rolling rotor compressor includes a crankshaft body 1, and the crankshaft body 1 includes a long axis section 11 and a short axis section 12, and the long axis section 11 of the crankshaft body 1 is along the axis A central exhaust hole 13 is provided in the direction, and the long axis section 11 of the crankshaft body 1 is provided with a transverse through hole 14 communicating with the central exhaust hole 13 in the radial direction.

[0013] In this crankshaft structure, a central exhaust hole is provided in the axial direction on the long axis section of the crankshaft body, and at the same time, a transverse through hole connecting the central exhaust hole is opened in the radial direction, so that the air flow is exhausted from the horizontal through hole in the long axis section of the crankshaft body and the center of the long axis section. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com