Rotary piston type compressor pump assembly

A rotary piston and compressor technology, which is applied in the direction of rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc., can solve the problem of unsatisfactory effects, insufficient noise reduction, and complex shapes and other problems to achieve the effect of eliminating fatigue fracture, smooth flow channel and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

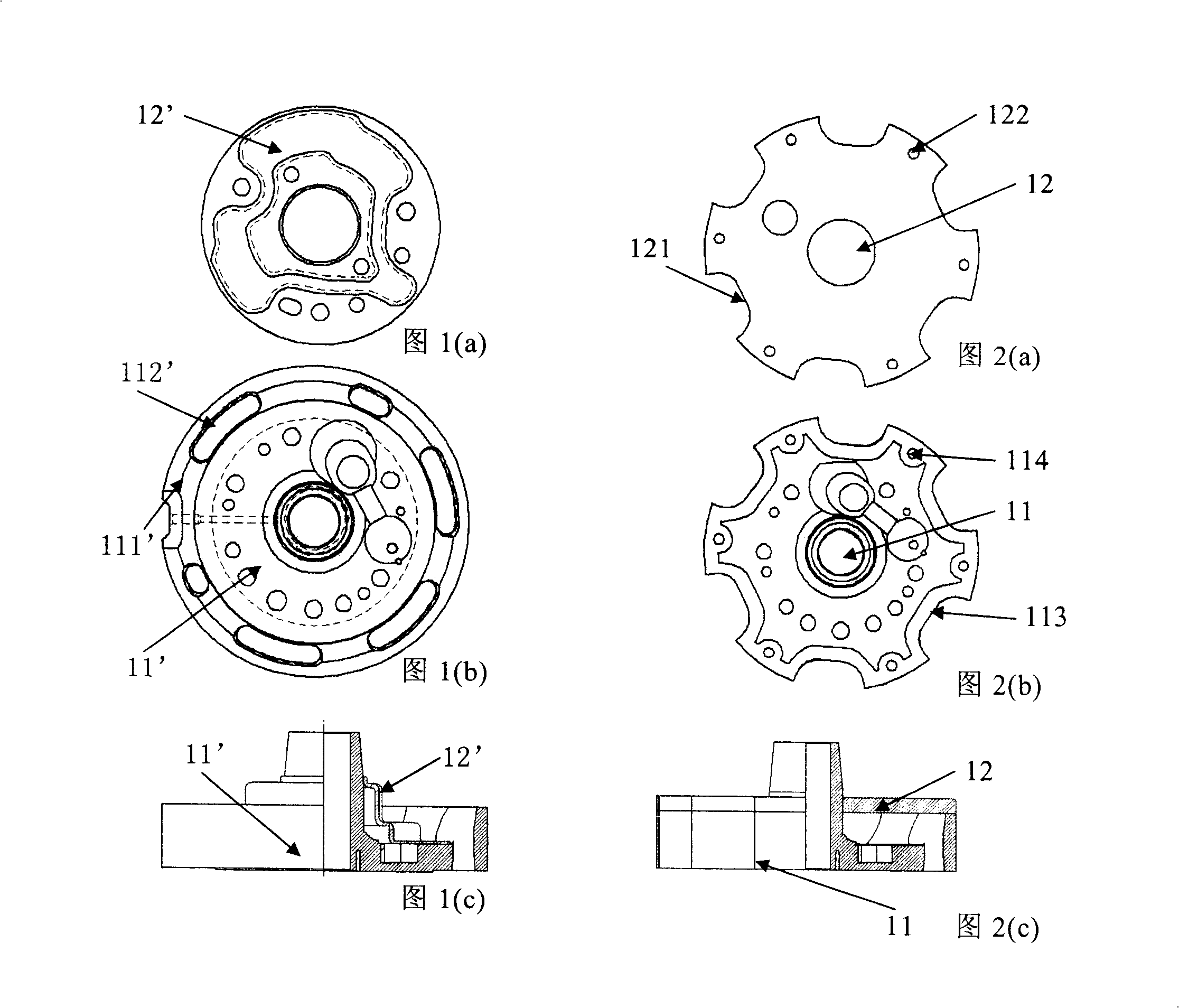

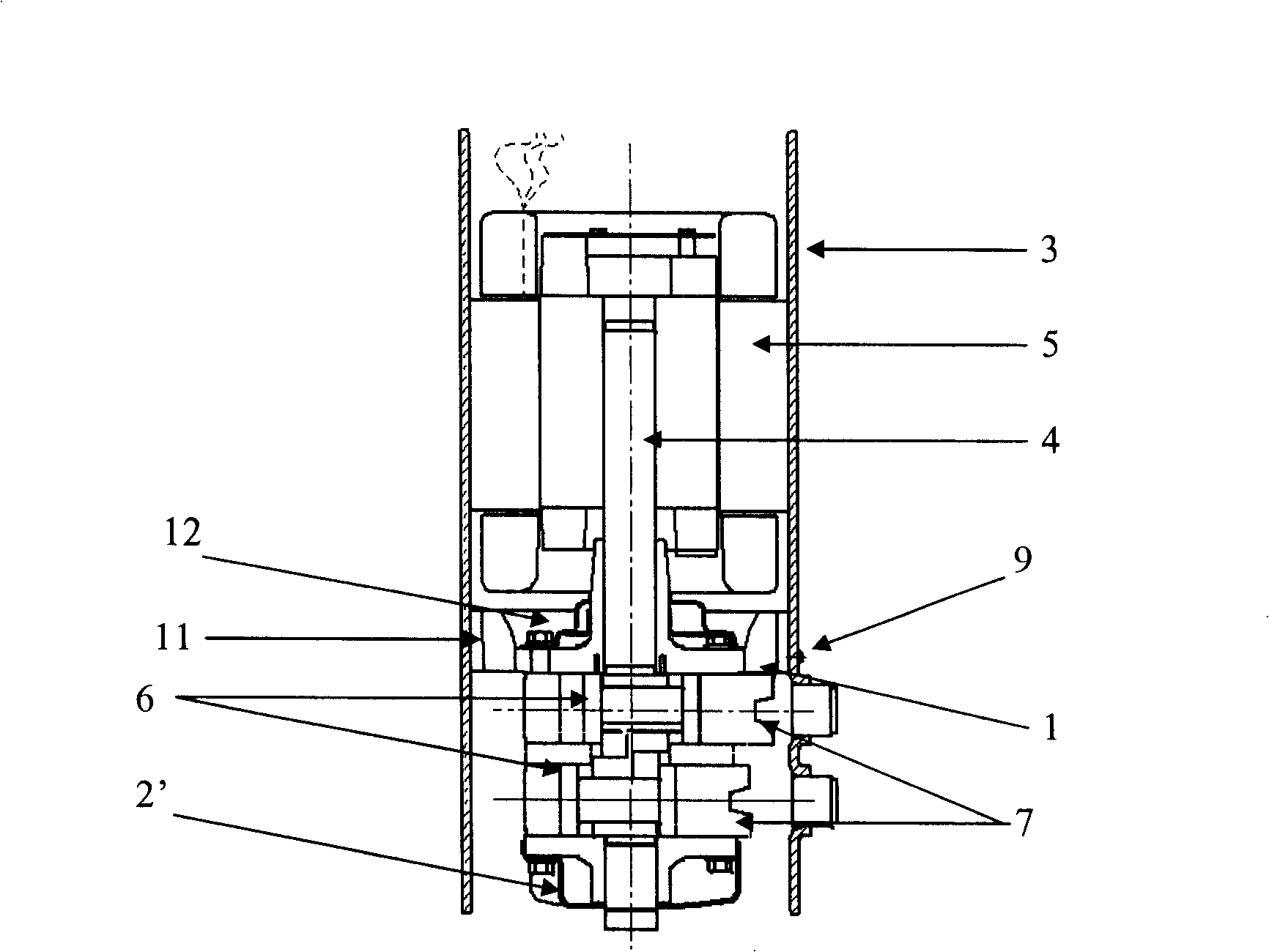

[0027] Such as image 3 As shown, the rotary piston compressor using the pump body assembly of the present invention includes a housing 3, a motor with a trimmed stator 5, and a pump body assembly located below the motor. The pump body assembly includes a crankshaft 4, an upper and a lower cylinder The head assembly 1, 2' and the working chamber of the rotary piston compressor constituted by the upper and lower cylinder head assemblies 1, 2' together with the piston 6 and the blade 7.

[0028] The pump body assembly is fixed by welding (welding point 9) with the casing 3 through its upper cylinder head assembly 1 .

[0029] Referring to Figure 2(a)~(c), the upper cylinder head assembly is composed of an upper cylinder head 11 and an upper muffler 12, and its features are:

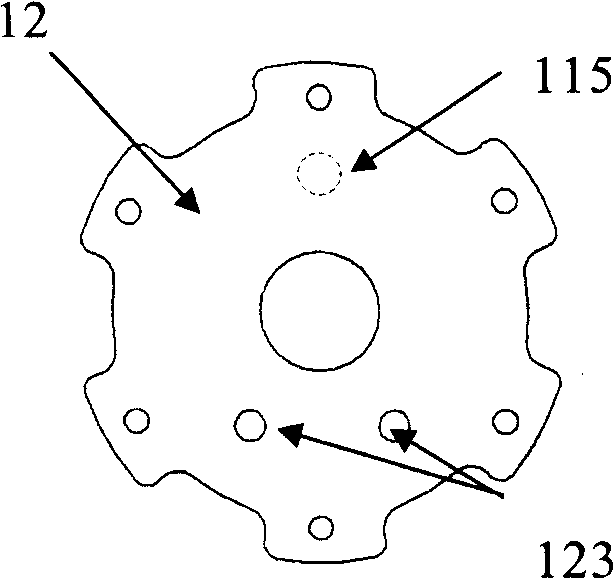

[0030] The outer ring of the upper cylinder head 11 has a groove 113 at the position corresponding to the cutting edge of the motor stator; the upper muffler 12 is a cover plate, and the outer ring of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com