Bearing seat and horizontal scroll compressor

A technology for scroll compressors and bearing housings, which is applied in the field of compressors, can solve the problems of reduced refrigeration efficiency of compressors, liquid shock and easy oil absorption of scroll disks, etc., and achieves the reduction of oil circulation rate, lower oil circulation rate, Avoid the effect of oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

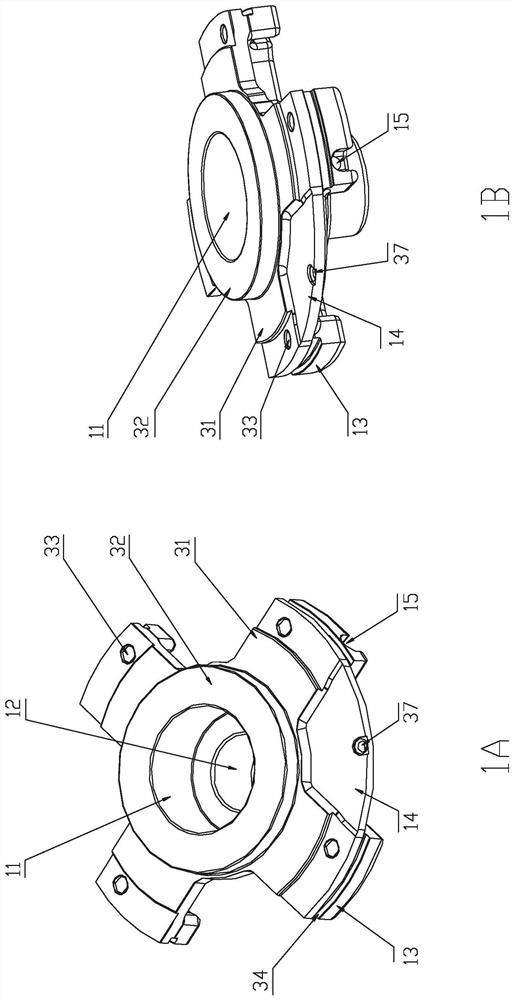

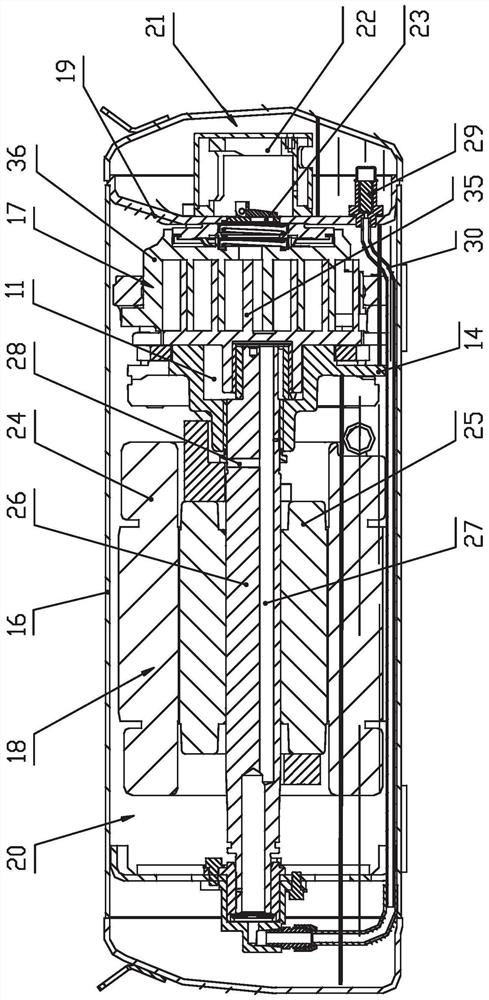

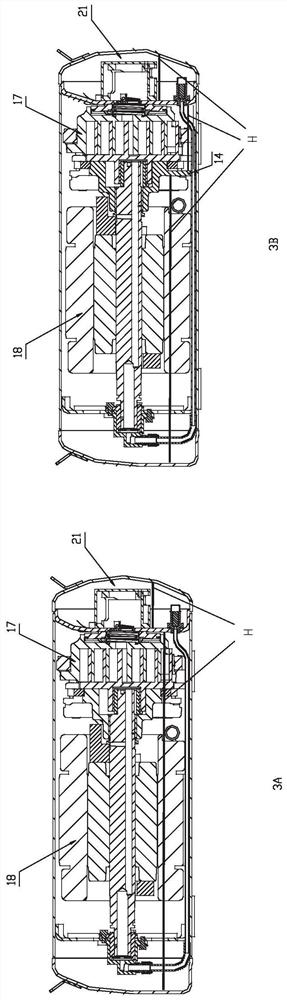

[0032] This embodiment proposes a bearing seat, such as figure 1 As shown in 1A and 1B, the bearing seat includes: a base, one end of the base is provided with a bearing chamber 11, and the other end of the base is provided with a bearing hole 12 penetrating into the bearing chamber 11; multiple mounting arms 13, multiple mounting arms 13 The arms 13 are respectively fixed on the peripheral surface of the base at intervals; the oil deflecting panel 14 is seamlessly fixed between two adjacent mounting arms 13 .

[0033] Wherein, a plurality of mounting arms 13 are provided at intervals for better interference fit of the bearing seat in the housing 16 of the horizontal compressor, and at the same time, can effectively prevent deformation of the housing 16 of the horizontal compressor. The oil baffle plate 14 blocks the lubricating oil on both sides of the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com